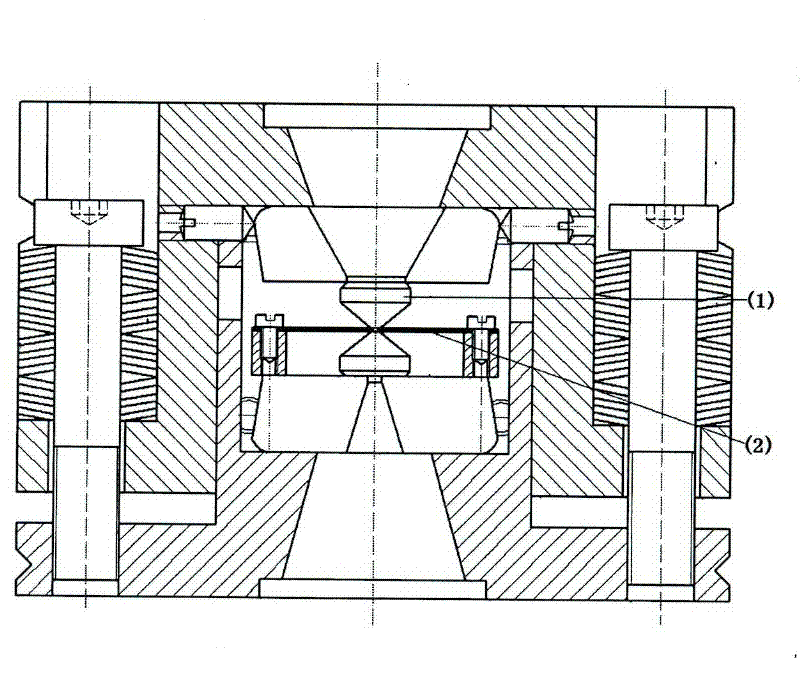

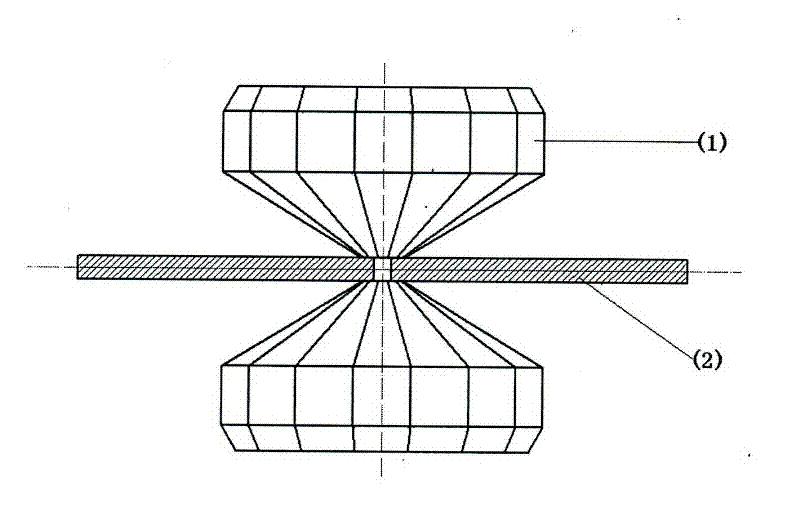

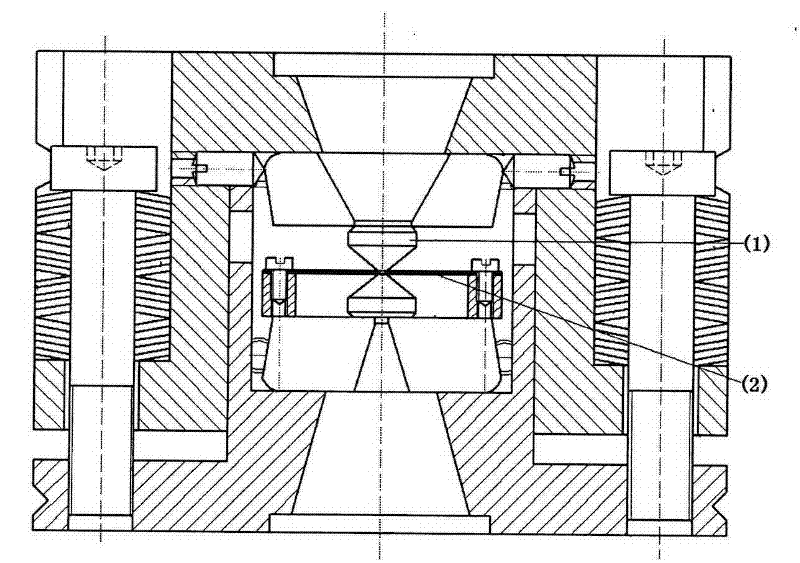

Diamond anvil cell zirconium-base amorphous alloy seal pad and preparation method thereof

A zirconium-based amorphous alloy, diamond topping technology, applied in the application of ultra-high pressure process and other directions, can solve the problems of difficult to find the position of the hole, time-consuming, limit the application of high-pressure experiments, etc., to achieve excellent mechanical properties, operation Simple, high-intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Get zirconium 50g, aluminum 2.69g, nickel 2.93g, copper 19g, the purity of above-mentioned metal raw material is 99.9%. Put the above-mentioned raw materials into a non-consumable electric arc furnace, and under the protection of argon, heat to 2000°C to melt into an alloy ingot, and repeat the melting twice to obtain an alloy ingot with uniform composition. A copper wire with a diameter of 50 μm is used as the core of the amorphous alloy to be suction-cast, fixed in the middle of the copper mold, and the surface of the copper wire is polished with high-grade sandpaper. Then put the above alloy ingot into a quartz tube, heat and remelt it through a high-frequency electromagnetic induction furnace, and inject it into the above copper mold equipped with a copper wire core. After cooling under the protection of argon, separate the copper mold and take out the copper wire core. After cutting, an amorphous alloy sealing gasket with a diameter of 50 μm and a thickness of 50 μ...

Embodiment 2

[0026] Get zirconium 60g, aluminum 3.34g, nickel 9.9g, copper 8.64g, the purity of above-mentioned metal raw material is 99.9%. Put the above-mentioned raw materials into a non-consumable electric arc furnace, and under the protection of argon, heat to 2000°C to melt into an alloy ingot, and repeat the melting 4 times to obtain an alloy ingot with uniform composition. A copper wire with a diameter of 120 μm is used as the core of the amorphous alloy to be suction-cast, fixed in the middle of the copper mold, and the surface of the copper wire is polished with high-grade sandpaper. Then put the above alloy ingot into a quartz tube, heat and remelt it through a high-frequency electromagnetic induction furnace, and inject it into the above copper mold equipped with a copper wire core. After cooling under the protection of argon, separate the copper mold and take out the copper wire core. After cutting, an amorphous alloy gasket with a diameter of 120 μm and a thickness of 50 μm i...

Embodiment 3

[0028] Get 66g of zirconium, 2.78g of aluminum, 12.21g of nickel, and 4.88g of copper. The purity of the above-mentioned metal raw materials is 99.9%. Put the above raw materials into a non-consumable electric arc furnace, under the protection of argon, heat to 2000°C to melt into an alloy ingot, and repeat the melting 7 times to obtain an alloy ingot with uniform composition. A copper wire with a diameter of 200 μm is used as the core of the amorphous alloy to be suction-cast, fixed in the middle of the copper mold, and the surface of the copper wire is polished with high-grade sandpaper. Then put the above alloy ingot into a quartz tube, heat and remelt it through a high-frequency electromagnetic induction furnace, and inject it into the above copper mold equipped with a copper wire core. After cooling under the protection of argon, separate the copper mold and take out the copper wire core. After cutting, an amorphous alloy gasket with a diameter of 200 μm and a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com