Multiple epitaxial growth method for realizing big length-to-diameter ratio ZnO nanowire array film based on low-temperature hydrothermal method

A nanowire array, large aspect ratio technology, applied in liquid phase epitaxy layer growth, polycrystalline material growth, single crystal growth and other directions, can solve the problem of high growth temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Concrete implementation steps of the present invention are as follows:

[0025] 1. Silicon substrate cleaning. The cleaning of the silicon substrate follows the principle of cleaning the organic matter first, and then cleaning the inorganic matter, and proceeds according to the process of supersonication (ultrasonic), boiling (acid boiling), and rinsing (rinsing).

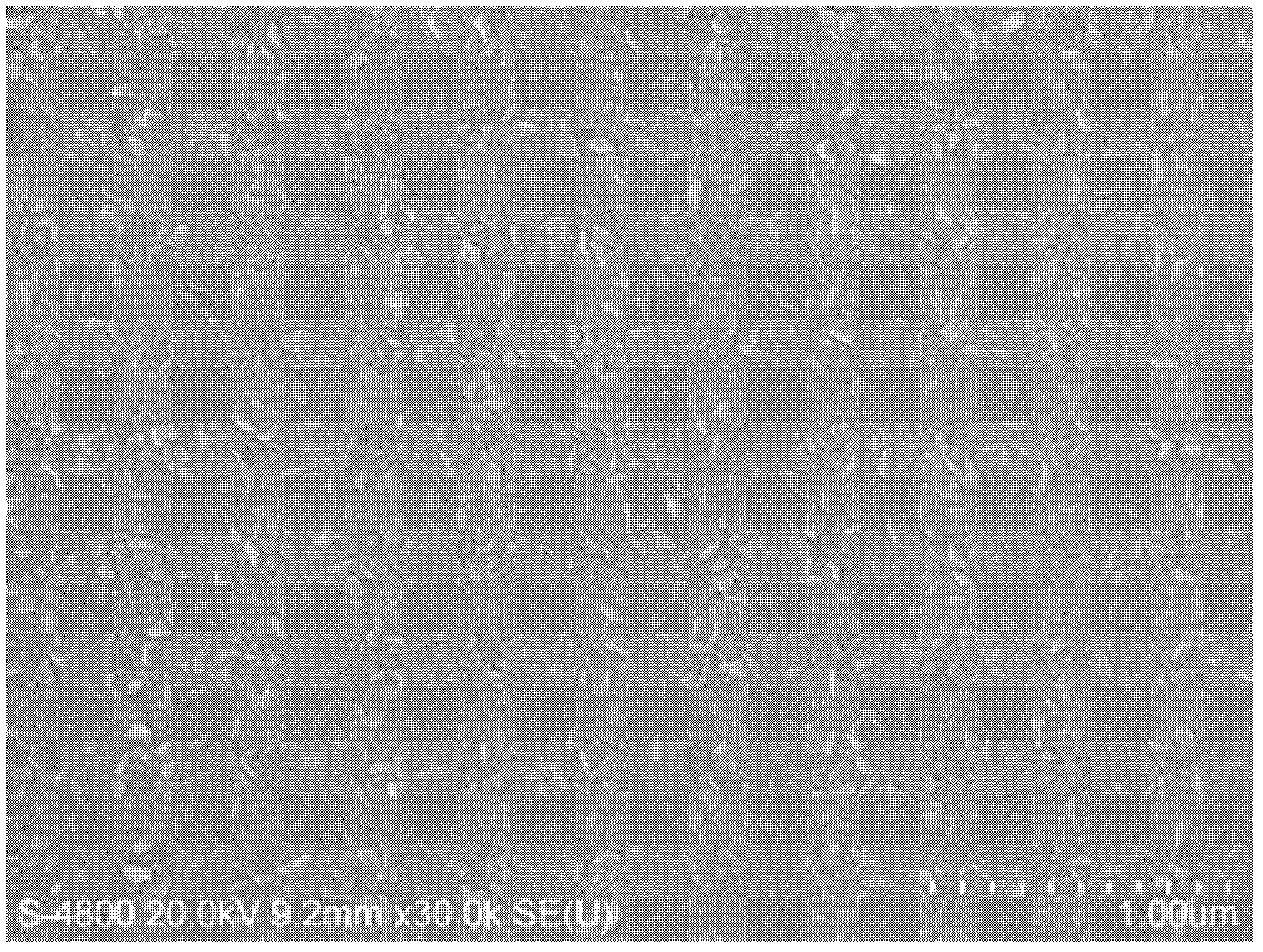

[0026] 2. Sputtering deposition of ZnO nano-seed layer. ZnO nano-seed layer was deposited by radio frequency magnetron sputtering process of ZnO ceramic target. The main process parameters are: vacuum degree 6E -4 Pa, oxygen flow: 5sccm, argon flow: 10sccm, radio frequency power: 120W, sputtering pressure: 1.0Pa, substrate heating temperature: 25080°C, sputtering time: 30min.

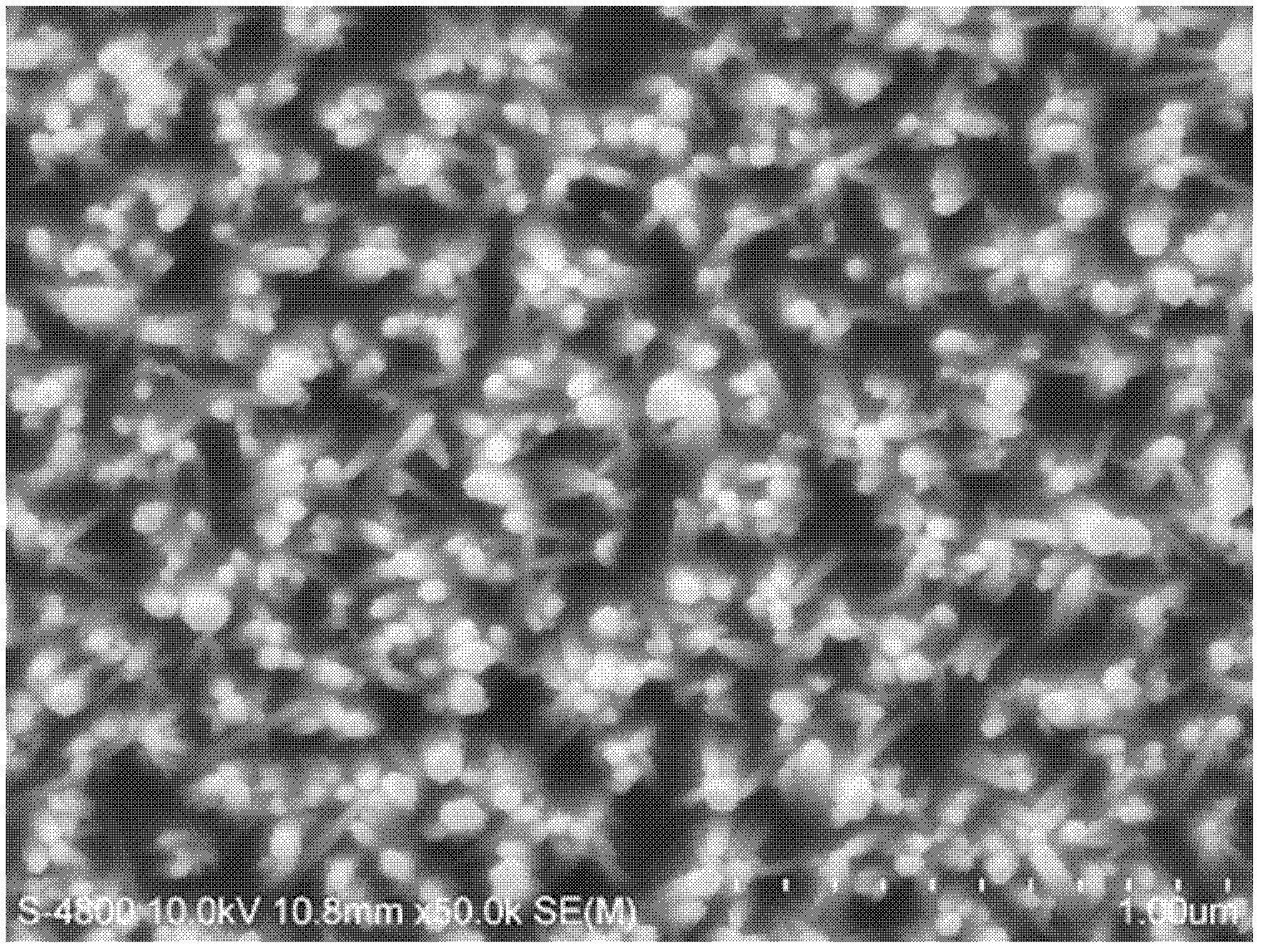

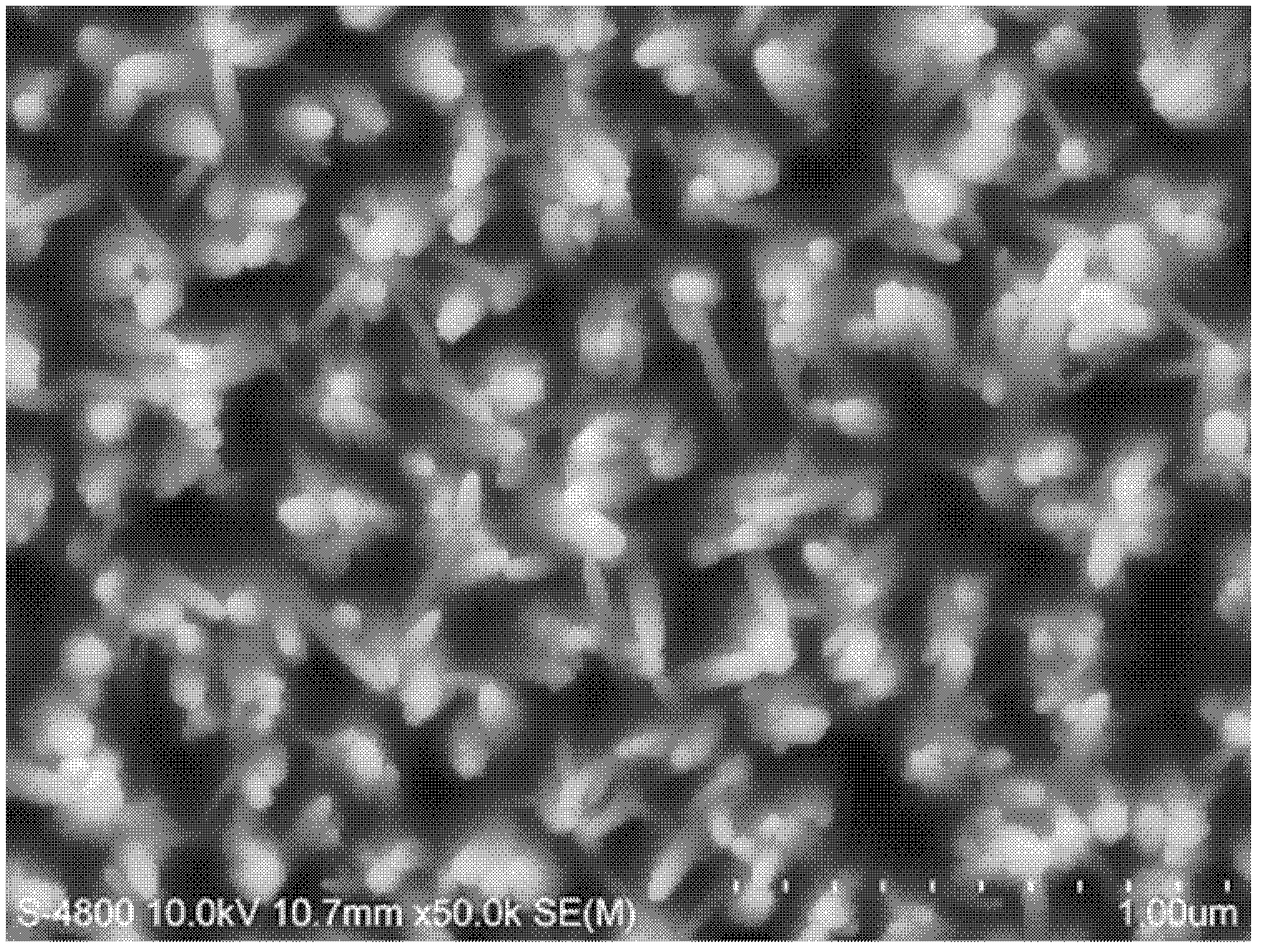

[0027] 3. Single self-assembly growth of ZnO nanowires. Form a mixed solution of 0.025mol / L zinc acetate dihydrate solution and hexamethylenetetraammonium solution at a volume ratio of 1:1, suspend the seed crystal film obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com