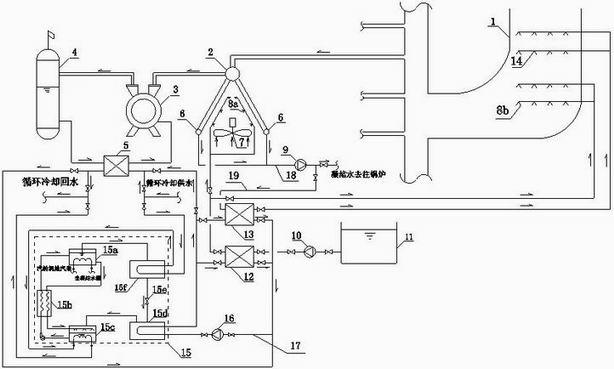

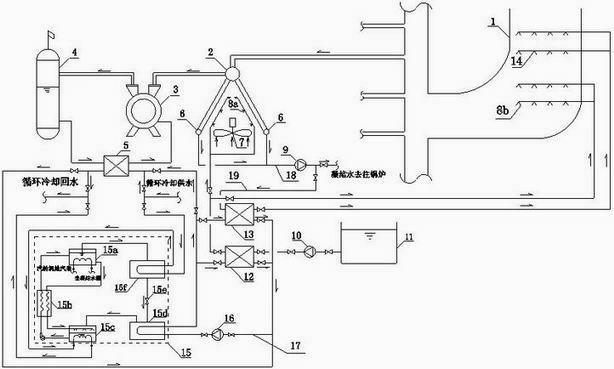

Energy-saving cooling method and system for reducing exhaust steam pressure of air-cooled unit in power plant

A technology of air-cooling unit and exhaust pressure, which is applied to steam/steam condensers, lighting and heating equipment, etc., which can solve the problems of reducing heat exchange effect, poor vacuum, and affecting the safe operation of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method of the present invention is as follows: installing refrigeration equipment in the air-cooling unit, dividing the frozen water produced by the refrigeration equipment into three paths to cool the relevant parts of the air-cooling unit. First: the working fluid of the water ring vacuum pump is cooled by chilled water through the cooler, and the temperature is reduced to the design value, which can increase the output of the vacuum pump; second: the industrial desalted water is cooled by the chilled water through the cooler, and pressurized by the water pump. The outlet air of the axial flow fan of the air-cooling unit is evaporatively cooled through the nozzle to reduce the inlet air temperature of the air-cooled radiator, thereby reducing the exhaust steam pressure; the other part enters the steam turbine exhaust pipe, directly mixes with the exhaust steam, and absorbs the latent heat of vaporization; the third : The condensed water is divided into two parts by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com