Analytical method for single substance calcium in core-spun calcium line

An analysis method and simple substance technology, which is applied in the field of testing and analysis, can solve the problems of no cored calcium wire, etc., and achieve the effects of wide applicability, simple and fast operation, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

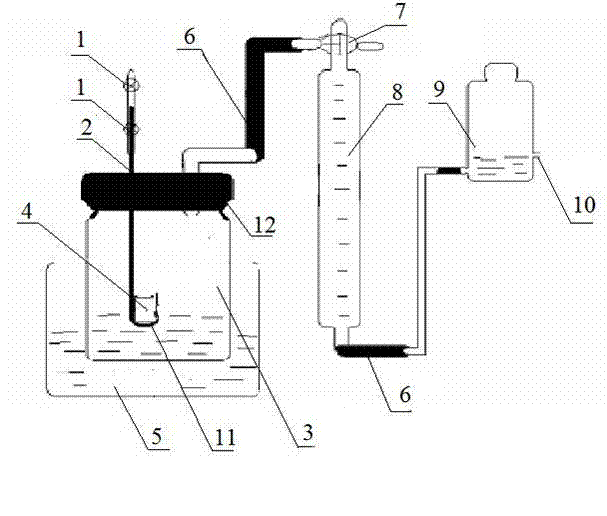

Method used

Image

Examples

Embodiment 1

[0022] The core-clad calcium wire sample is an analysis sample before the steel plant furnace, and the analysis includes the following steps:

[0023] Cut off a core-spun calcium wire sample with a length of about 5cm, quickly pour out the inner filling material (material to be analyzed) into a sealed bag, weigh the total weight with a ten-thousandth balance, and then put 15.7097g of the material to be analyzed into the small test Transfer the sample cup to a 2000 mL reaction bottle filled with water and saturated with hydrogen in advance, and tighten the rubber stopper; turn the two-way piston of the trachea to connect the trachea to the vent hole of the piston; raise the level bottle to exhaust as much as possible Air, turn the trachea piston to connect the trachea to the reaction bottle, and place it for 2 minutes; immerse the sample cup fixing ring in water, shake the reaction bottle gently to make the sample fully react with the water, and place the reaction bottle in a co...

Embodiment 2

[0025] The core-clad calcium wire sample is another batch of samples before the furnace of the iron and steel plant. The analysis includes the following steps:

[0026] Cut a core-spun calcium wire sample with a length of about 6cm, quickly pour out the inner filling material (material to be analyzed) into a sealed bag, weigh the total weight with a ten-thousandth balance, and then put 18.3640g of the material to be analyzed into the small test Transfer the sample cup to a 2000 mL reaction bottle filled with water and saturated with hydrogen in advance, and tighten the rubber stopper; turn the two-way piston of the trachea to connect the trachea to the vent hole of the piston; raise the level bottle to exhaust as much as possible Air, turn the trachea piston to connect the trachea to the reaction bottle, and place it for 2 minutes; immerse the sample cup fixing ring in water, and shake the reaction bottle gently to make the sample fully react with the water; then place the reac...

Embodiment 3

[0028] The core-spun calcium wire samples are samples from different manufacturers in front of the steel plant furnace, including the following steps:

[0029] Cut off a core-spun calcium wire sample with a length of about 7cm, quickly pour out the inner filling material (material to be analyzed) into a sealed bag, weigh the total weight with a ten-thousandth balance, and then put 18.1378g of the material to be analyzed into the small test Transfer the sample cup to a 2000 mL reaction bottle filled with water and saturated with hydrogen in advance, and tighten the rubber stopper; turn the two-way piston of the trachea to connect the trachea to the vent hole of the piston; raise the level bottle to exhaust as much as possible Air, turn the trachea piston to connect the trachea to the reaction bottle, and place it for 2 minutes; immerse the sample cup fixing ring in water, and shake the reaction bottle gently to make the sample fully react with the water; then place the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com