Silicon two-way transient voltage suppression diode and manufacture method thereof

A technology of transient voltage suppression and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., to achieve the effects of good reliability, small size, and large instantaneous power absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

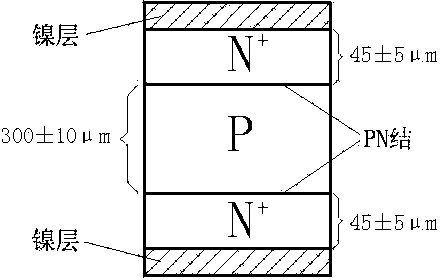

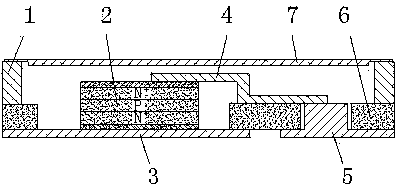

[0019] Embodiments of the present invention: a method of manufacturing a silicon bidirectional transient voltage suppressor diode of the present invention is to diffuse two N regions on both sides of a P-type silicon chip, plate nickel on the surface of the two N regions, and obtain positive hexagons after slicing. Form the chip, package the chip in the tube shell, and lead out the electrode to obtain a silicon bidirectional transient voltage suppression diode. The diffusion uses a diffusion mesa process for phosphorus diffusion. The P-type silicon wafer is a P-type dislocation-free silicon single wafer, the resistivity is between 0.09-0.15Ω.cm, and the thickness is between 290-310 μm. The thickness of the N region is between 40-50 μm. The surface of the N region is nickel-plated after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com