Lithium ion battery anode material layered lithium manganese oxide and manufacturing method thereof

A positive electrode material layer, lithium-ion battery technology, applied in battery electrodes, manganate/permanganate, circuits, etc., can solve the problems of difficult control of air pressure, high specific capacity, difficult preparation, etc., and achieve easy temperature adjustment, The effect of mild reaction conditions and high initial capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of layered lithium manganese oxide as positive electrode material of lithium ion battery is characterized in that: its preparation method is as follows:

[0028] The first step, the precursor (Mn 1-x m x ) 2 o 3 Preparation of:

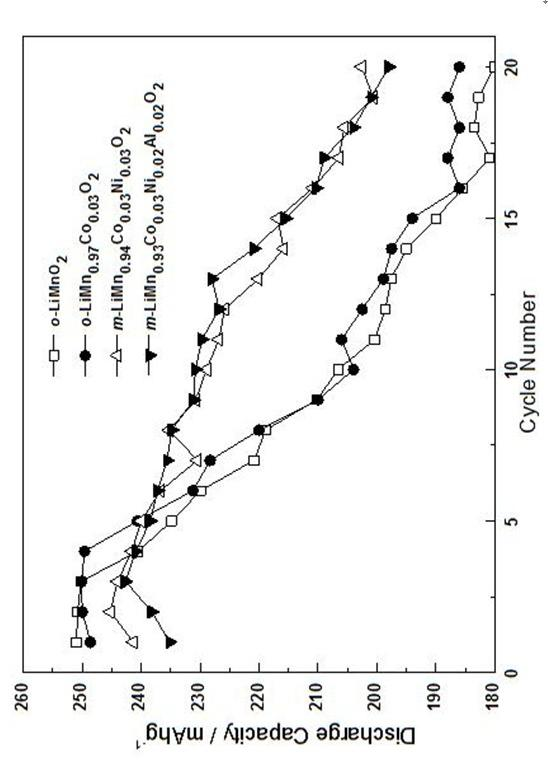

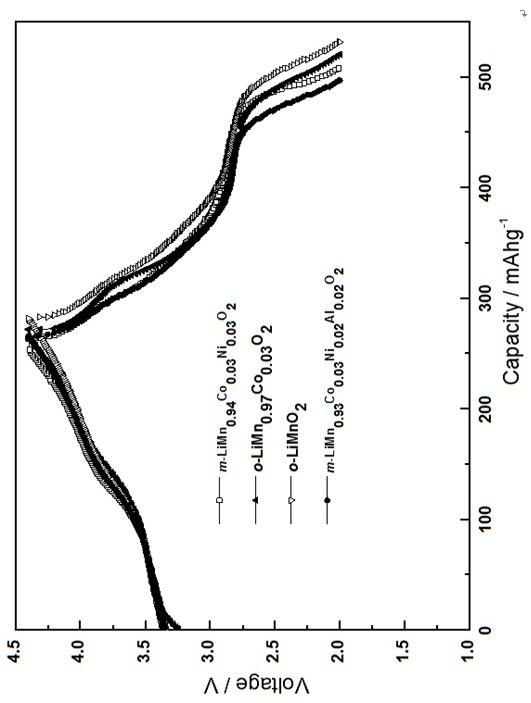

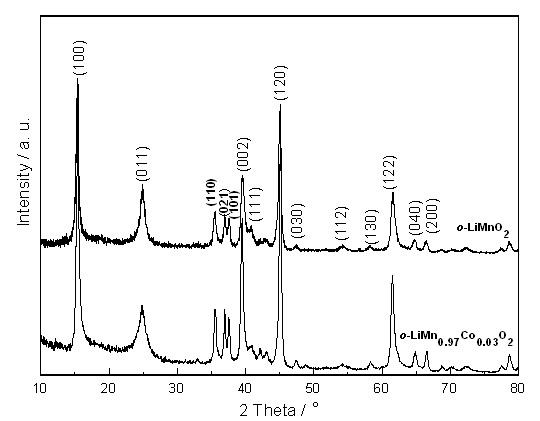

[0029] (1): Put soluble manganese sulfate, cobalt sulfate, nickel sulfate, aluminum sulfate, and chromium chloride in the ratio of metal atomic ratio Mn / M=(1-x) / x, where Mn is manganese, M is Co, Ni, One or more of Al and Cr, the range of x is 0≤x≤0.15, and when 0≤x≤0.05, the obtained layered lithium manganate is an orthorhombic structure, when 0.05<x≤0.15, The obtained layered lithium manganate has a monoclinic structure; then it is dissolved in deionized water to prepare a mixed solution with a total concentration of 1-4mol / L for later use;

[0030](2): Use ammonia water or ammonium salt as a complexing agent, add NaOH or KOH to prepare an ammonia-alkali solution with a molar concentration of 1~4mol / L, and set asid...

Embodiment 1

[0040] The preparation method of layered lithium manganese oxide as positive electrode material of lithium ion battery is characterized in that: its preparation method is as follows:

[0041] The first step, the preparation of the precursor:

[0042] (1): Dissolve soluble manganese sulfate in deionized water to prepare a mixed solution with a total concentration of 2mol / L for later use;

[0043] (2): Use ammonia water or ammonium salt as a complexing agent, add NaOH or KOH to prepare an ammonia-alkali solution with a molar concentration of 2mol / L, and set aside;

[0044] (3): First add the ammonia-alkali solution and deionized water described in (2) into the reactor, so that the pH value of the solution in the reactor is 9-12, and the volume of the solution accounts for 1 / 6-1 of the volume of the reactor. / 5, then evenly add the mixed solution described in (1) and the ammonia-alkali solution described in (2) into the reaction kettle described in (3), and control the temperatu...

Embodiment 2

[0053] The preparation method of layered lithium manganese oxide as positive electrode material of lithium ion battery is characterized in that: its preparation method is as follows:

[0054] The first step, the preparation of the precursor:

[0055] (1): Dissolve soluble manganese sulfate and cobalt sulfate in deionized water according to the ratio of atomic ratio Mn:Co =0.975:0.025, and prepare a mixed solution with a total concentration of 3mol / L for later use;

[0056] (2): Use ammonia water or ammonium salt as a complexing agent, add NaOH or KOH to prepare an ammonia-alkali solution with a molar concentration of 3mol / L, and set aside;

[0057] (3): First add the ammonia-alkali solution and deionized water described in (2) into the reactor, so that the pH value of the solution in the reactor is 9-12, and the volume of the solution accounts for 1 / 6-1 of the volume of the reactor. / 5, then evenly add the mixed solution described in (1) and the ammonia-alkali solution descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com