Extraction method of mineral concentrate for environmental restoration and application thereof

An extraction method and a concentrated liquid technology, which are applied in the field of extraction of mineral concentrated liquids for environmental remediation, can solve problems such as narrow restoration of the environmental surface and a single object of action, and achieve the effects of wide application, simple operation, and rich sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of Environmental Mineral Concentrates

[0030] 1) Sieve the andesite after crushing and drying, pour 5.5 parts by weight of the sieved andesite powder into 7 parts by weight of dilute sulfuric acid with a concentration of 20%, stir well and let stand for 24 hours.

[0031] 2) Add 3.5 parts by weight of citric acid to the mixture obtained in step 1), stir well and let stand for 24 hours.

[0032] 3) 15 parts by weight of liquid obtained after filtering the mixture obtained in step 2) is mineral concentrate. Add 85 parts by weight of distilled water to the mineral concentrate, mix it evenly and put it into an acid-proof container for dark preservation.

Embodiment 2

[0034] Environmental mineral concentrate is used to make super humus to inhibit the dissolution of heavy metals in soil

[0035] (1) Cow dung and straw are mixed in a ratio of 1:1 by weight, and the mineral concentrate that yeast and example 1 are made is added thereto, and every 1 cubic meter of mixed material adds 200g yeast and 30ml mineral concentrate , the concentrated mineral solution needs to be diluted with water and then added to the mixture, the water content of the mixture is adjusted to 60-65%, and fully stirred and mixed.

[0036](2) Pile at least 10 cubic meters of mixed material sprayed with mineral liquid into a heap with a height of 1.5 m and a width of 2.5 m, and carry out aerobic fermentation and decomposition. After three fermentations, about three months. The first fermentation takes one month, and the temperature will exceed 70°C on the third day after the pile is completed. Therefore, the pile needs to be turned for the first time on the fifth day. Afte...

Embodiment 3

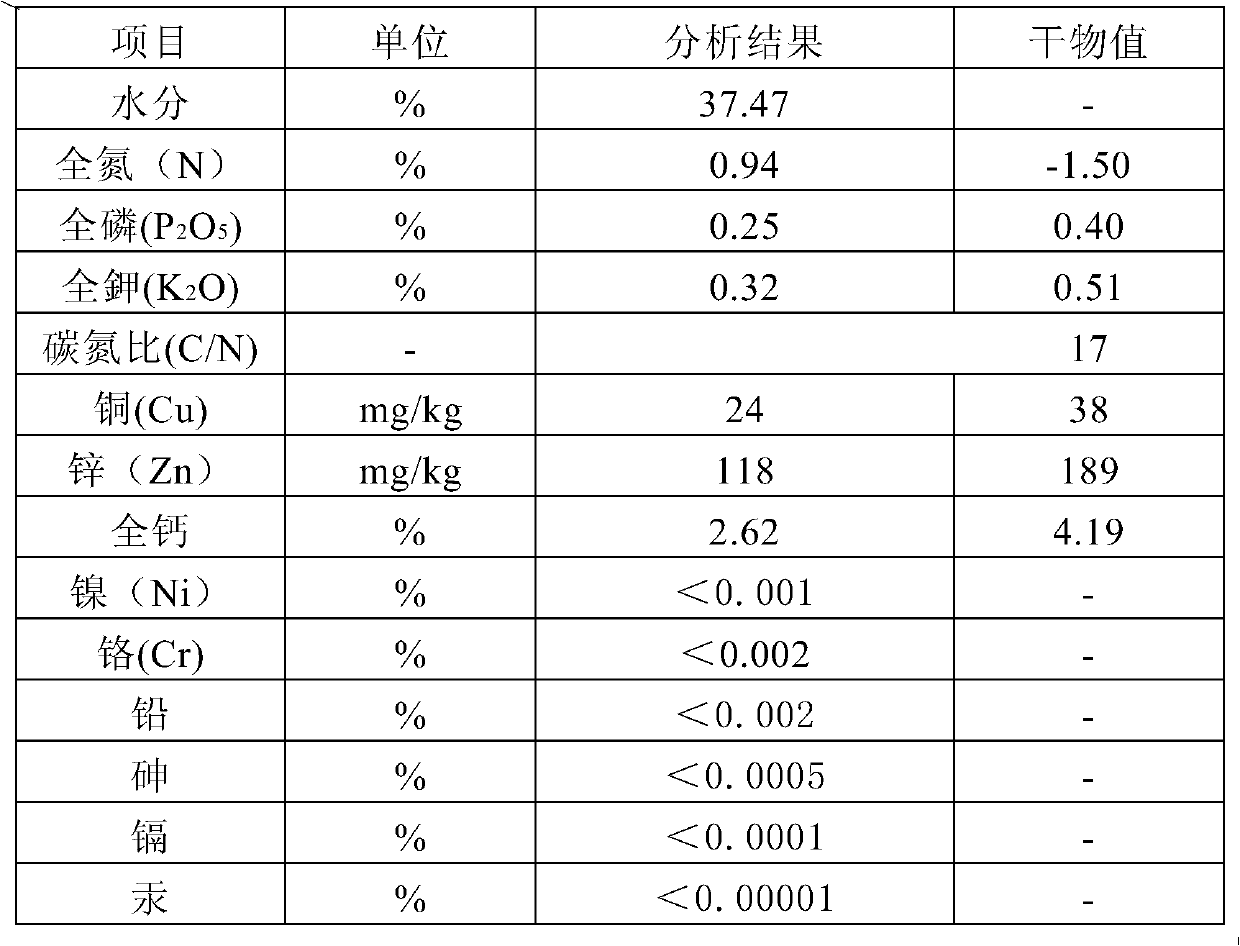

[0041] Test of Mineral Concentrate Used in Domestic Sludge Removal of Heavy Metals

[0042] (1) Mix the sludge and rice straw at a volume ratio of 1:3. The content of lead and its compounds in the sludge is 0.11 mg / L, and the content of arsenic and its compounds is 0.015 mg / L. Add 200g yeast and the mineral concentrated solution of 30ml embodiment 1 in the mixed material of cubic meter, this mineral concentrated solution needs to add after diluting with water, the water content of mixed material is adjusted to 60%, carry out sufficient stirring and mixing.

[0043] (2) At least 10 cubic meters (maintaining temperature) of the mixture sprayed with mineral liquid are piled up into a pile with a height of 1.5m and a width of 2.5m for aerobic fermentation and decomposition. After three fermentations, about three months. The first fermentation takes one month, and the temperature will exceed 70°C on the third day after the pile is completed. Therefore, the first turning over is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com