Nickel series hydrogenation catalyst, preparation method thereof and application thereof

A hydrogenation catalyst and catalyst technology, applied in chemical instruments and methods, through selective hydrogenation refining, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of impurity resistance needs to be improved, catalyst price is high, Short regeneration cycle and other issues, to achieve the effect of long regeneration cycle, strong resistance to impurities and sol, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

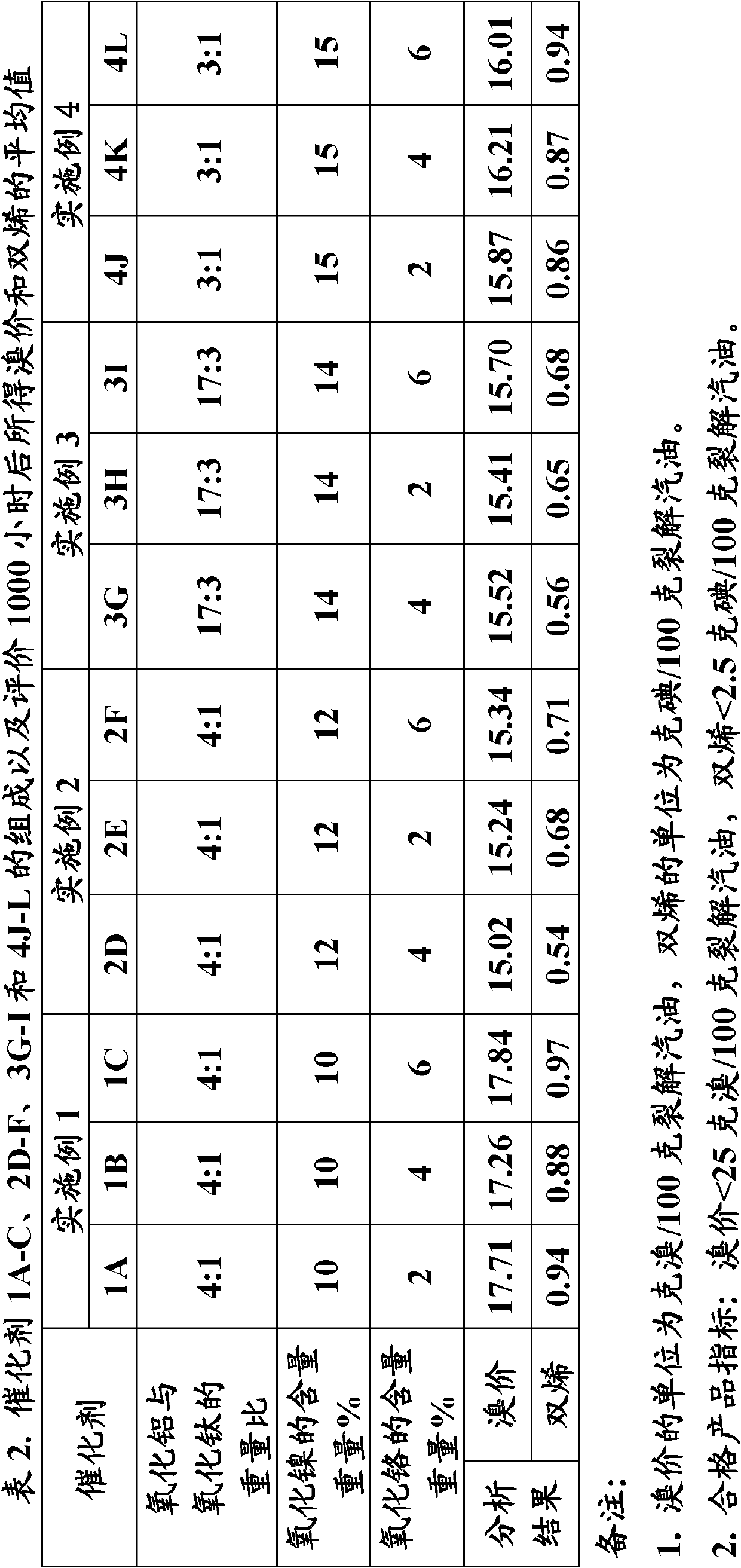

Embodiment 1

[0042] Preparation of vector

[0043] The specific surface area of 100g is 176m 2 / g and a clover-shaped alumina with a pore volume of 0.54mL / g was impregnated with 50mL of titanium sulfate in a 0.6g / mL dilute sulfuric acid solution for 2 hours, dried at 110°C for 10 hours, and calcined at 700°C for 4 hours , 125 g of alumina-titania composite carrier 1 was obtained, wherein the weight ratio of alumina to titania was 4:1.

[0044] Catalyst preparation

[0045] Add 5.02g of nickel nitrate to 5mL of water, stir to dissolve, add 0.56g of chromium nitrate while stirring, adjust the pH value to 5 with dilute nitric acid, impregnate 10g of alumina-titania composite carrier 1 in it for 3 hours, filter out and impregnate The composite carrier 1 was dried at 120°C for 6 hours and calcined at 600°C for 5 hours to obtain 11.4g of catalyst 1A with a specific surface area of 162m 2 / g, the pore volume is 0.52mL / g.

[0046] Add 5.02g of nickel nitrate into 5mL of water, stir to ...

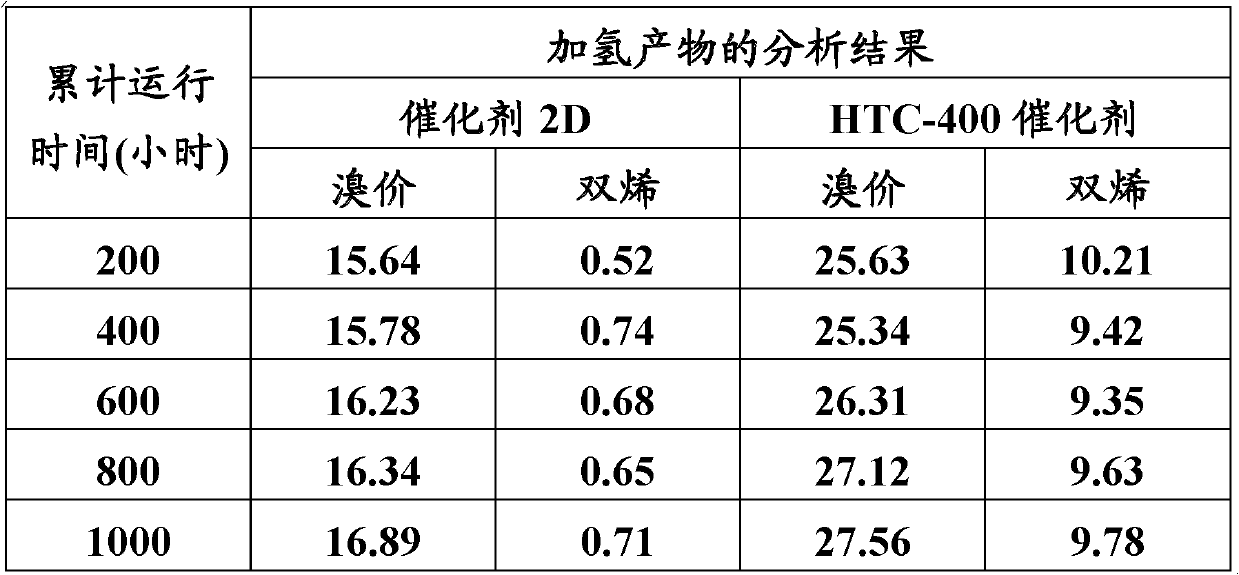

Embodiment 2

[0050] Preparation of vector

[0051] The specific surface area of 95g is 176m 2 / g and clover-shaped alumina with a pore volume of 0.54mL / g was impregnated with 50mL tetraethyl titanate in 0.526g / mL cyclohexane solution for 2 hours, dried at 120°C for 8 hours, and then dried at 700°C Calcined at lower temperature for 5 hours, 119 g of alumina-titania composite carrier 2 was obtained, wherein the weight ratio of alumina to titania was 4:1.

[0052] Catalyst preparation

[0053] Add 5.8g of nickel nitrate into 5mL of water, stir to dissolve, add 1.02g of chromium nitrate while stirring, adjust the pH value to 5 with dilute nitric acid, impregnate 10g of alumina-titania composite carrier 2 in it for 4 hours, filter out and impregnate The composite carrier 2 was dried at 120°C for 6 hours and calcined at 600°C for 5 hours to obtain 11.9g of catalyst 2D with a specific surface area of 178m 2 / g, the pore volume is 0.53mL / g.

[0054] Add 5.8g of nickel nitrate into 5mL ...

Embodiment 3

[0058] Preparation of vector

[0059] The specific surface area of 175g is 176m 2 / g and a clover-shaped alumina with a pore volume of 0.54mL / g was impregnated with 108mL tetraethyl titanate in 0.81g / mL cyclohexane solution for 3 hours, dried at 120°C for 8 hours, and then dried at 600°C Calcined at the bottom for 4 hours to obtain 205 g of alumina-titania composite carrier 3, wherein the weight ratio of alumina to titania was 17:3.

[0060] Catalyst preparation

[0061] Add 6.8g of nickel nitrate to 5mL of water, stir to dissolve, add 1.12g of chromium nitrate while stirring, adjust the pH value to 5 with dilute nitric acid, impregnate 10g of alumina-titania composite carrier 3 in it for 4 hours, filter out and impregnate The composite carrier 3 was dried at 120°C for 6 hours and calcined at 500°C for 5 hours to obtain 12.2g of catalyst 3G with a specific surface area of 184m 2 / g, the pore volume is 0.52mL / g.

[0062] Add 6.8g of nickel nitrate to 5mL of water, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com