Preparation method of zirconic acid yttrium transparent ceramics

A technology of transparent ceramics and zirconic acid, which is applied in the field of preparation of yttrium zirconate transparent ceramics, can solve the problems of transparent ceramics without yttrium zirconate, and achieve the effects of simple process, high sintering density and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

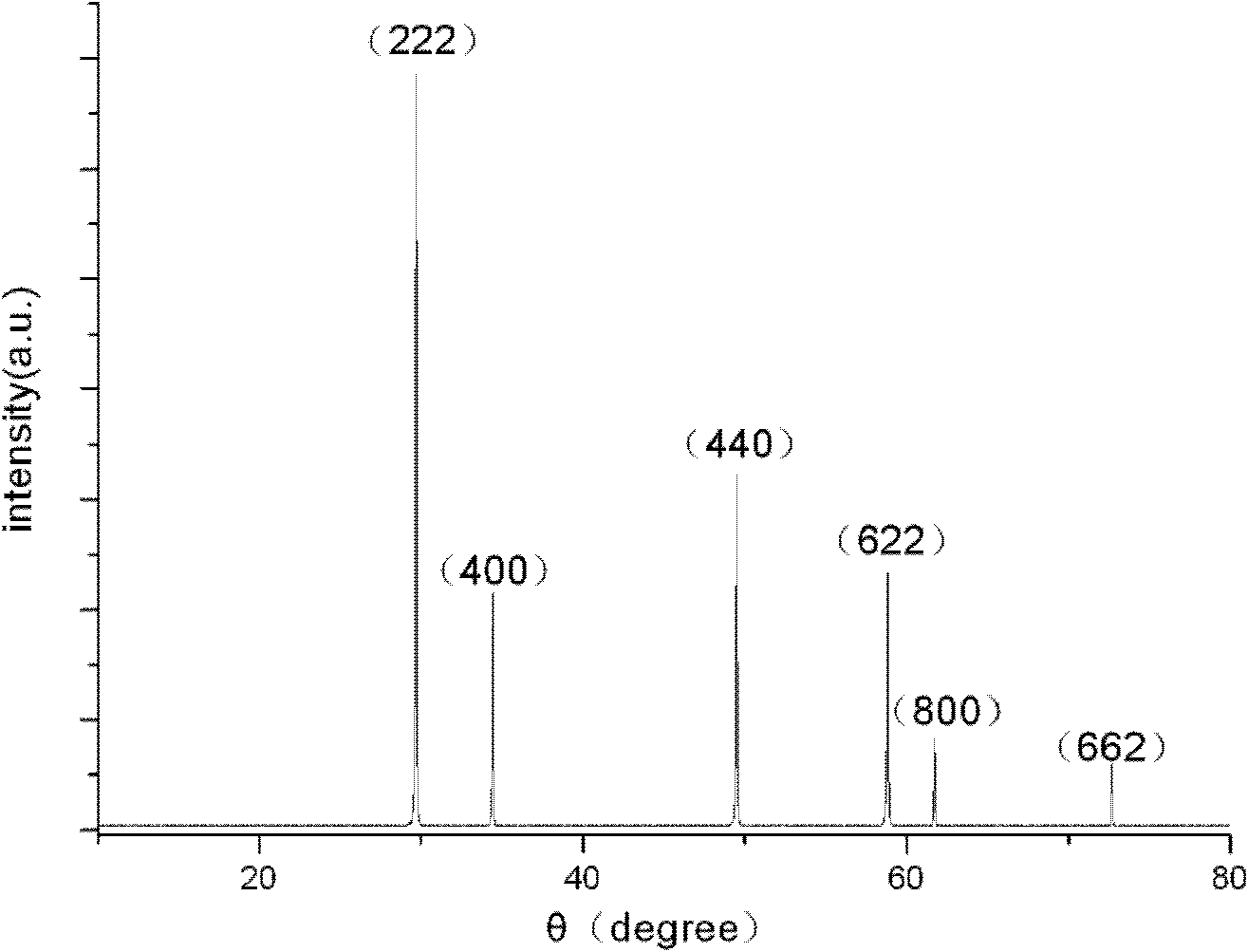

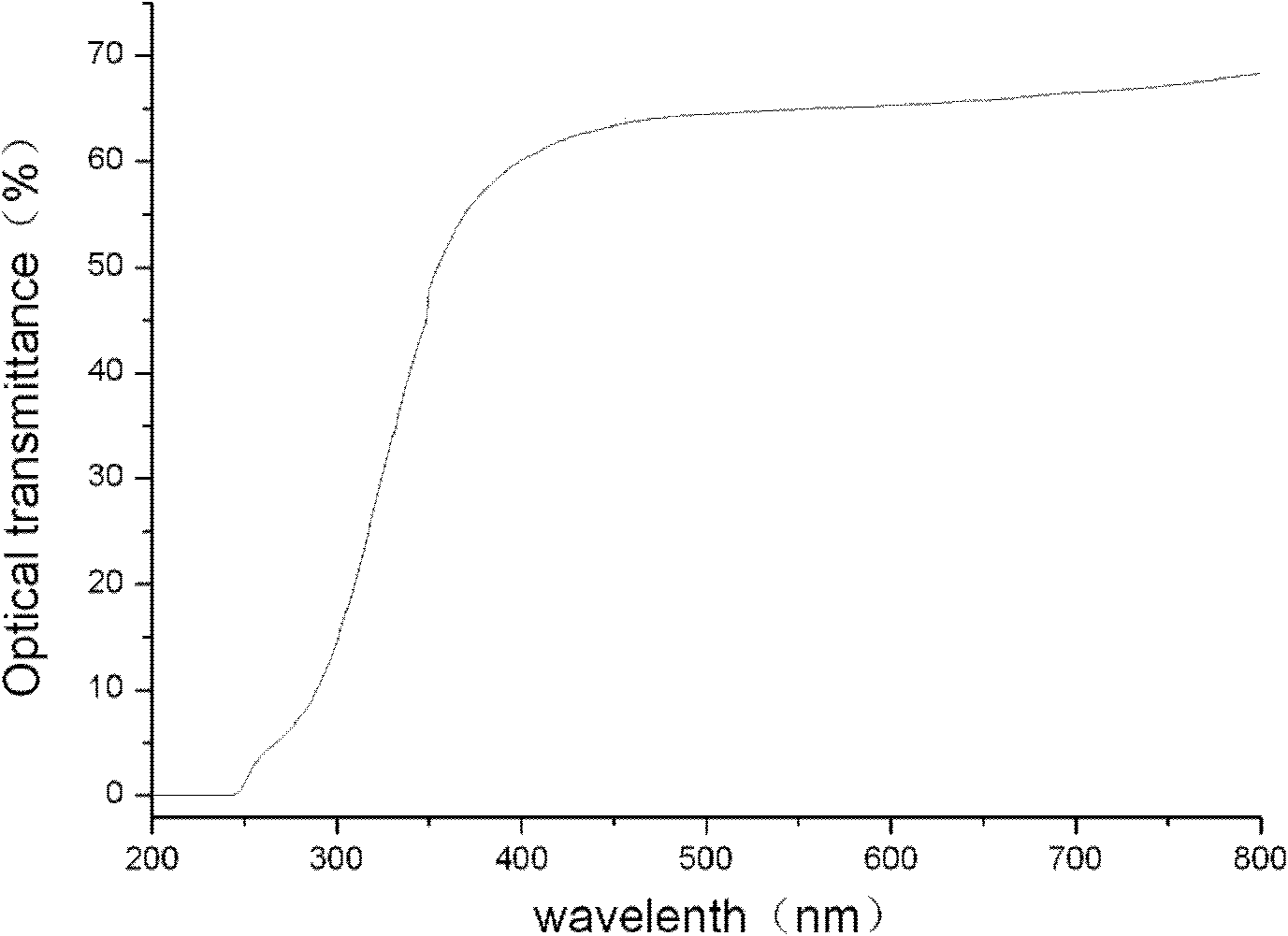

Embodiment 1

[0025] In this example, yttrium zirconate powder was synthesized by combustion method. Zirconium nitrate (Zr(NO 3 ) 4 ·XH 2 O, 99.9%) and yttrium nitrate (Y(NO 3 ) 3 , 99.995%) is configured into a solution according to the molar ratio of Zr and Y as 1:1, then add fuel glycine, and adjust the pH value of the solution to 3 to 5 with ammonia water, heat the solution on a magnetic stirrer, and wait until the water in the solution After a short period of time, the combustion reaction is carried out on the electric furnace, and then the obtained precursor powder is placed in a muffle furnace for heat treatment of the powder, and the particle size of the powder after ball milling and sieving is 50-100nm. Then dry pressing (5MPa, holding pressure 1min) and cold isostatic pressing (200MPa, holding pressure 3min), and successively through processes such as pre-calcination, vacuum sintering, annealing heat treatment, obtain yttrium zirconate (Y 2 Zr 2 o 7 ) transparent ceramics. ...

Embodiment 2

[0027] In this example, yttrium zirconate powder was synthesized by a combustion method. Zirconium nitrate (Zr(NO 3 ) 4 ·XH 2 O, 99.9%) and yttrium oxide (Y 2 o 3 , 99.995%) according to the molar ratio of Zr and Y is 1: 1 metering dissolved in nitric acid solution, then add fuel glycine, and adjust the pH value of the solution with ammonia water to be 3 ~ 5, the solution is heated on a magnetic stirrer, until the solution When there is less water, move it to an electric furnace for combustion reaction, and then place the obtained precursor powder in a muffle furnace for powder heat treatment, and the particle size of the powder after ball milling and sieving is 50-100nm. Then dry pressing (5MPa, holding pressure 1min) and cold isostatic pressing (200MPa, holding pressure 3min), and successively through processes such as pre-calcination, vacuum sintering, annealing heat treatment, obtain yttrium zirconate (Y 2 Zr 2 o 7 ) transparent ceramics. The process conditions of ...

Embodiment 3-4

[0029] The preparation process is the same as in Example 1, and the process conditions such as powder heat treatment, molding, pre-calcination, vacuum sintering and annealing are shown in Table 1.

[0030] Table 1. Synthesis process conditions of yttrium hafnate transparent ceramics

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com