Super-micro powder composite impervious ceramic precast block for refining furnace and preparation method

A ceramic prefabricated block and superfine powder technology, which is applied in the field of prefabricated refractory materials, can solve the problems of increasing enterprise costs, energy consumption, and environmental pollution, and achieve the effects of reducing pollution and inclusions, strong wear resistance, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

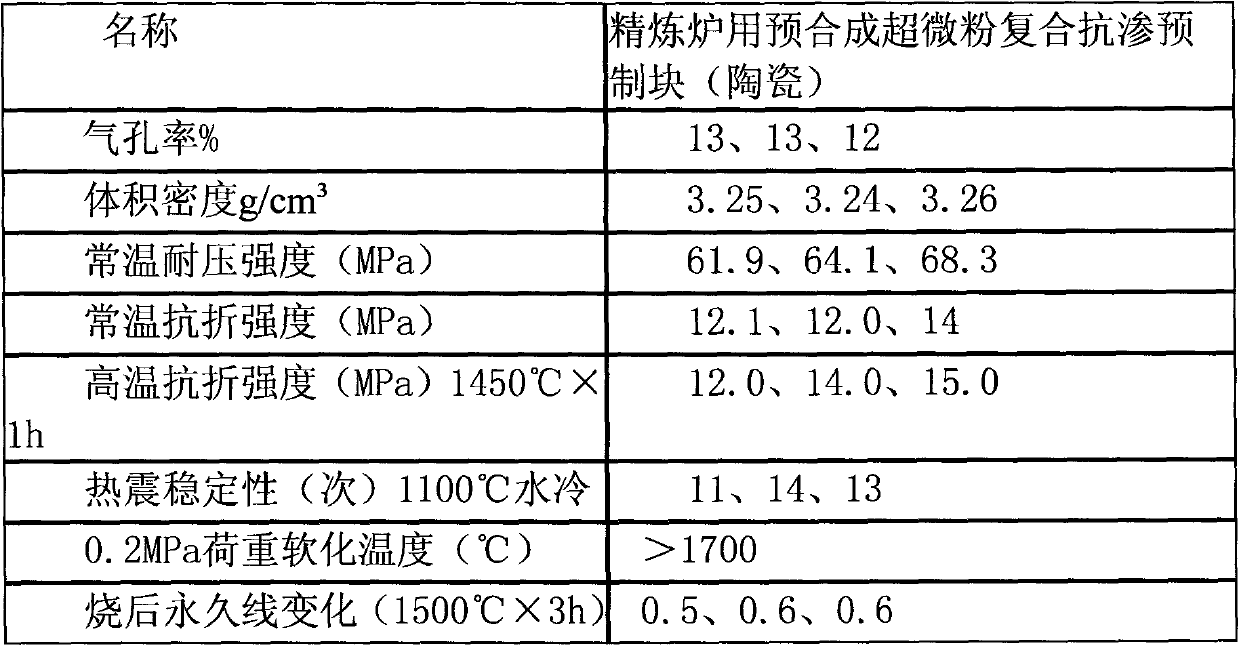

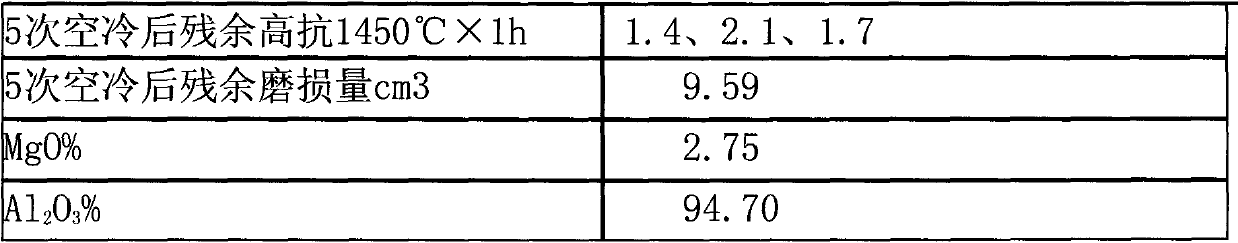

Embodiment 1

[0026] Preparation method of ultrafine powder composite anti-permeability ceramic prefabricated block for refining furnace, electro-fused aluminum-rich spinel (Al 2 o 3% content ≥ 90%) 70 parts, pre-synthesized spinel powder (electrically fused and sintered spinel single-or composite) 16 parts, alumina powder 8 parts; high-performance alumina water reducer 2 parts, pure 4 parts of calcium aluminate cement, plus 0.015 parts of the total weight of electro-fused pre-synthesized alumina-rich spinel, alumina micropowder, pre-synthesized spinel, high-performance alumina water reducer, and pure calcium aluminate cement coagulant The organic explosion-proof fiber is put into a strong sand mixer for pre-mixing for 13 minutes, and the mixed material is used for later use; the mixed material is added to 5% water, and the stirring is continued for 6 minutes to make the raw material into a concrete slurry; the vibration and decompression molding method is adopted That is - inject the prep...

Embodiment 2

[0028] Fused alumina-rich spinel (Al 2 o 3 % content ≥ 90%) 72 parts, pre-synthesized spinel powder (single or composite use of fused and sintered spinel) 15 parts, alumina powder 8 parts; high-performance alumina water reducer 2 parts, pure aluminum 3 parts of calcium aluminate cement, plus 0.013 parts of the total weight of electric fusion pre-synthesized aluminum-rich spinel, alumina micropowder, pre-synthesized spinel, high-performance alumina water reducer, and pure calcium aluminate cement coagulant Organic explosion-proof fiber, put it into a strong sand mixer for pre-mixing for 14 minutes, and the mixed material is ready for use; add the mixed material to 5.5% water, continue stirring for 5 minutes, and make the raw material into concrete slurry; adopt the vibration decompression molding method -Inject the prepared concrete slurry into the pre-assembled mold, perform high-frequency vibration and vacuum treatment to remove air bubbles; wet heat preservation and mainten...

Embodiment 3

[0030] Fused alumina-rich spinel (Al 2 o 3 % content ≥ 90%) 73 parts, pre-synthesized spinel powder (single or composite use of fused and sintered spinel) 17 parts, alumina powder 7 parts; high-performance alumina water reducer 1 part, pure aluminum 2 parts of calcium aluminate cement, plus electrofusion pre-synthesized aluminum-rich spinel, alumina micropowder, pre-synthesized spinel, high-performance alumina water reducer, pure calcium aluminate cement coagulant 0.014 of the total weight 100% organic explosion-proof fiber, put it into a strong sand mixer for pre-mixing for 13 minutes, and the mixed material is ready for use; add 6% water to the mixed material, continue stirring for 6 minutes, and make the raw material into concrete slurry; use vibration and decompression molding to form The method is - inject the prepared concrete slurry into the pre-assembled mold, perform high-frequency vibration and vacuum treatment to remove air bubbles; wet heat preservation and curing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com