Rare-earth modified aluminum nitrogen swing spout castables

A swing nozzle and rare earth modification technology, which is applied in the field of rare earth modified aluminum nitrogen swing nozzle castables, can solve the problems of short service life, easy cracking, poor erosion resistance, etc., to reduce costs and save energy consumption , The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

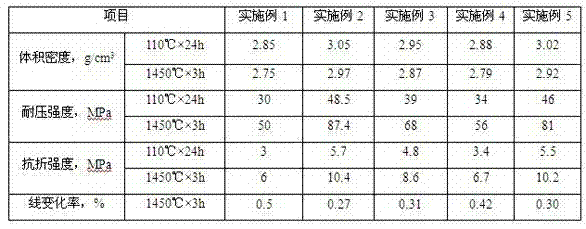

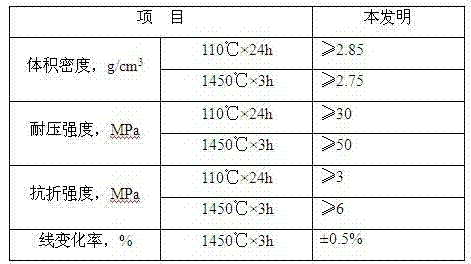

Examples

Embodiment 1

[0026] A rare earth modified aluminum nitrogen swing nozzle castable, the weight percentage of the components contained in it is:

[0027] Corundum aggregate 65%, of which the mass ratio of fused corundum to sintered tabular alumina is 15:85, silicon carbide 15%, rare earth oxide 5% including La 2 o 3 , Y 2 o 3 , NdF 3 ,Nd 2 o 3 , 7% metal silicon, 8% binder, and 5% of the above total admixture, wherein the binder is α-Al 2 o 3 Micropowder 5%, cement 2% and silica fume 1%.

Embodiment 2

[0029] A rare earth modified aluminum nitrogen swing nozzle castable, the weight percentage of the components contained in it is:

[0030] Corundum aggregate 75%, of which the mass ratio of fused corundum to sintered tabular alumina is 22:78, 8% of silicon carbide with a particle size of less than 0.088mm and 0.5mm, 2% of rare earth oxides, and metallic silicon with a particle size of 35μm 7%, binder 8%, and additives accounting for 7% of the above total amount, of which the rare earth oxide is 0.5% La 2 o 3 , 0.5%Y 2 o 3 , 0.13%NdF 3 , 0.87%Nd 2 o 3 ; The binder is α-Al with a particle size of 0.5 μm 2 o 3 Micropowder 5%, cement 2% and silica fume 1%.

Embodiment 3

[0032] A rare earth modified aluminum nitrogen swing nozzle castable, the weight percentage of the components contained in it is:

[0033] Corundum aggregate 70%, of which the mass ratio of fused corundum to sintered tabular alumina is 18:82, 11% of silicon carbide with a particle size of less than 0.088mm and 0.5mm, 4% of rare earth oxides, and metallic silicon with a particle size of 50μm 3%, binder 12%, and admixtures of metal aluminum and sodium tripolyphosphate accounting for 6% of the above total amount, of which the rare earth oxide is 2.5% La 2 o 3 , 1.0%Y 2 o 3 , 0.37%NdF 3 , 0.13%Nd 2 o 3 ; The binder is α-Al with a particle size of 1.5 μm 2 o 3 Micropowder 5%, cement 4% and silica fume 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com