Highly-antibacterial polypropylene composite material and preparation method thereof

A technology of antibacterial polypropylene and composite materials, applied in the field of high antibacterial polypropylene composite materials and their preparation, and high antibacterial polypropylene composite materials, can solve the problems of difficult generation of active groups, high surface energy of particles, and high cost of silver, and achieve Effects of maintaining photocatalytic activity, improving antibacterial ability, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

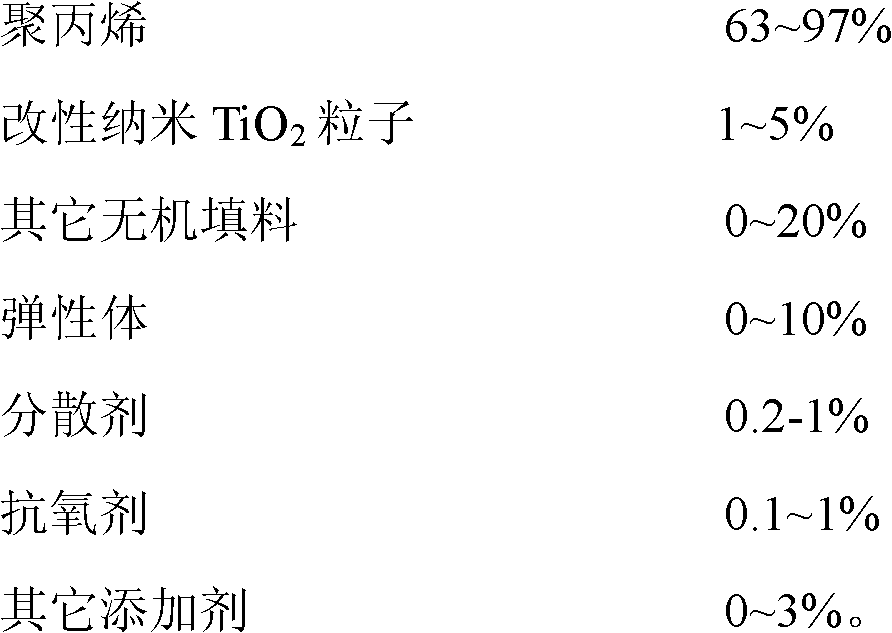

Method used

Image

Examples

Embodiment Construction

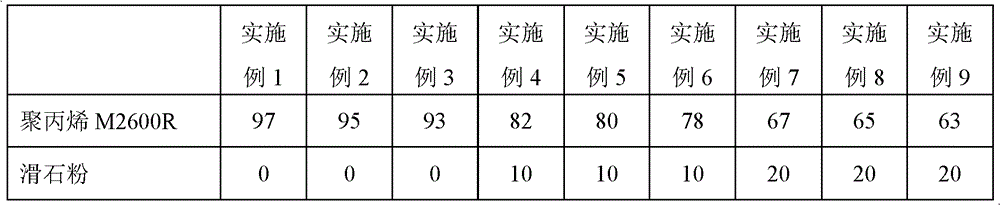

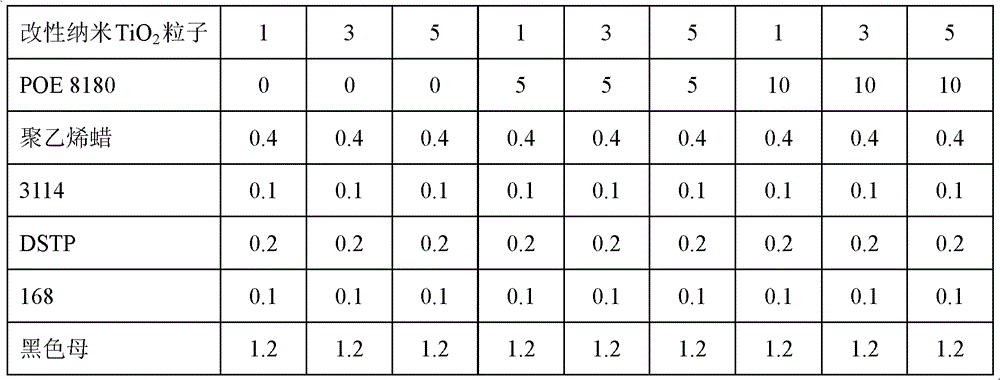

[0027] Below in conjunction with embodiment, the present invention is described in further detail:

[0028] In the composite material formulations of Examples and Comparative Examples, polypropylene is a copolymerized polypropylene with a melt flow rate of 28 g / 10 min (test conditions: 230° C.×2.16 kg) produced by Shanghai Petrochemical Company, and its trade name is M2600R. Nano-TiO 2 The particles are anatase titanium dioxide, the particle size is ≤5nm, and the specific surface area is more than 200m 2 / g. doped nano TiO 2 Particles: Nano TiO by ball milling 2 The particles are obtained by doping 5% nanometer zinc oxide (ZnO, produced by Shanghai Chemical Co., Ltd.). Modified Nano TiO 2 Particles: Nano-TiO will be doped 2 The particles are prepared by modifying with silane coupling agent (KH550, commercially available). As other inorganic fillers, talcum powder with a particle size of 5 microns is selected. The elastomer is a linear ethylene-octene copolymer produced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com