High solid epoxy paint formula and preparation process as well as application thereof

A technology of epoxy coating and preparation process, which is applied in the direction of epoxy resin coating, anti-corrosion coating, anti-fouling/underwater coating, etc., can solve the problem of low coating quality, achieve good coating film quality, good surface adaptability, and energy saving high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

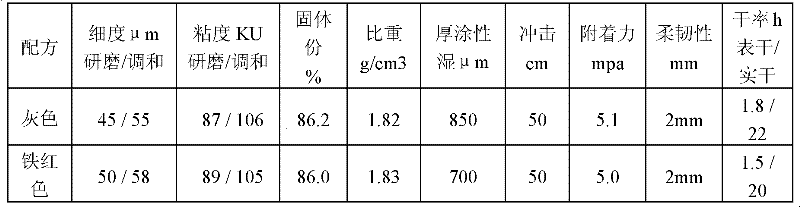

Embodiment 1

[0048] The mass ratio formula of gray high solid epoxy paint is as follows:

[0049] The specific composition and content of the main agent are as follows:

[0050] Epoxy resin: 23.7 parts

[0051] Reactive diluent E10P: 1 part

[0052] Titanium dioxide BA01-01: 5 parts

[0053] Epoxy diluent n-butanol: 10 parts

[0054] Bentonite 908: 1.0 parts

[0055] Dispersant ATU: 0.30 parts

[0056] Barite powder 500 mesh: 13 parts

[0057] Talcum powder 600 mesh: 15 parts

[0058] Superfine barium sulfate: 28 parts

[0059] Anti-sagging agent 3300: 2.5 parts

[0060] Black epoxy color paste: 0.5 parts

[0061] The specific composition and content of curing agent are as follows:

[0062] Epoxy diluent n-butanol: 15 parts

[0063] Polyamide curing agent: 10 parts

[0064] Mannich alkali curing agent: 75 parts

[0065] When in use, the mass ratio of the main agent and the curing agent is 84:16.

[0066] The preparation process of this gray high solid epoxy paint is as follow...

Embodiment 2

[0076] The mass ratio formula of iron red high solid epoxy paint is as follows:

[0077] The specific composition and content of the main agent are as follows:

[0078] Epoxy resin E-51: 23.9 parts

[0079] Reactive diluent E10P: 2 parts

[0080] Epoxy diluent n-butanol: 10 parts

[0081] Bentonite 908: 0.8 parts

[0082] Dispersant ATU: 0.3 parts

[0083] Barite powder 500 mesh: 12 parts

[0084] Talcum powder 600 mesh: 14 parts

[0085] Iron oxide red: 6 parts

[0086] Superfine barium sulfate: 28 parts

[0087] Anti-sagging agent 3300: 3.0 parts

[0088] The specific composition and content of curing agent are as follows:

[0089] Epoxy diluent n-butanol: 12 parts

[0090] High molecular polyamide: 10 parts

[0091] Mannich alkali curing agent: 78 parts

[0092] When in use, the mass ratio of the main agent and the curing agent is 84:16.

[0093] The preparation process of this gray high solid epoxy paint is as follows:

[0094] The preparation process steps o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com