Method for quickly extracting herbaceous fibers in factory fermentation mode by using full-function strains

A herbal fiber, factory-like technology, applied in the field of functional strains and the use of microorganisms to treat herbal fiber raw materials, can solve the problems of not being able to completely get rid of the negative effects of chemical catalysts, complicated bacteria preparation technology, and high cost of enzyme preparations. The effect of low production cost and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

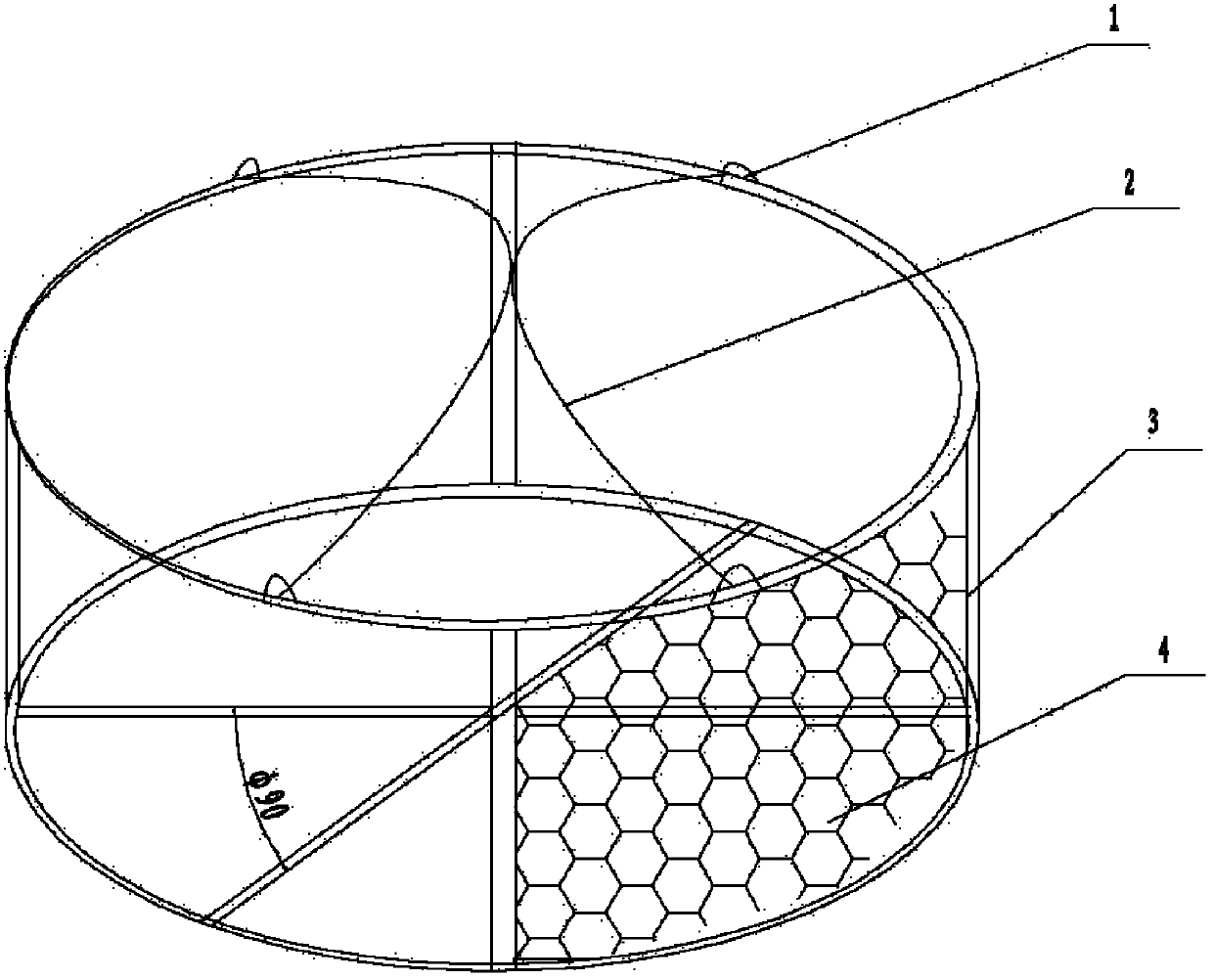

Image

Examples

Embodiment 1

[0055] Using the Chinese Academy of Agricultural Sciences hemp processing enzyme preparation pilot workshop and some equipment of Hunan Yuanjiang Star Hemp Industry Co., Ltd., the hemp bast of different varieties and origins purchased from hemp producing areas such as Yunnan and Anhui were subjected to a biological test with a batch size of 300kg. Degumming, specifically includes the following steps:

[0056] (1) Pretreatment of hemp bast: Unbundle hemp bast, straighten it and divide it into hemp handles, each with a mass of 0.8kg, and feed it to the roller rolling device for rolling, so that the raw material structure is evenly damaged but not pulled Broken fiber, undamaged area of raw material structure ≤ 150mm 2 .

[0057] (2) Activated bacterial suspension: first, inoculate the long-term preserved Dickeya dadanti strain into the improved broth culture solution for activation for 5 hours, so that the dormant strain becomes the activated bacterial suspension, and take 1.0...

Embodiment 2

[0062] Using the pilot plant of hemp processing enzyme preparation of the Chinese Academy of Agricultural Sciences and some of the test equipment of Changsha University of Science and Technology, the kenaf bast of different varieties and origins purchased from kenaf producing areas such as Zhejiang and Anhui were subjected to biopulping with a batch size of 300kg. Specifically include the following steps:

[0063] (1) Pretreatment of kenaf bast: Unbundle kenaf bast, straighten it and divide it into hemp handles, each with a mass of 1.2kg, and feed it into a cutting machine for shearing. The length of the cut fragments of raw materials is 200- 400mm.

[0064] (2) Activated bacterial suspension: same as Example 1.

[0065] (3) Factory fermentation: including the following steps,

[0066] a. Put the sheared kenaf bast evenly into the hanging basket, and at the same time, use 32-36°C surface water to dilute the active bacteria suspension until the live bacteria content is 8×10 ...

Embodiment 3

[0073] Under laboratory conditions, ramie, kenaf bast, jute bast, hemp bast, flax raw stem, asparagus, wheat straw and other herbal fiber raw materials were biologically tested in batches of 30-1000g by using Dickeya dadanti strain. Degumming or biopulping test, specifically including the following steps:

[0074] (1) Activated bacterial suspension: same as Example 1.

[0075] (2) Pretreatment of herbal fiber raw materials: divide herbal fiber raw materials such as ramie, kenaf bast, jute bast, hemp bast, flax stem into small pieces and straighten them, then feed them into roller rolling device or similar machinery for grinding Press to make the raw material structure evenly damaged but not to break the fiber, wherein, the undamaged area of the raw material structure is ≤150mm 2 or, the herbaceous fiber raw materials such as kenaf bast, jute bast, hemp bast, asparagus grass, wheat straw, etc. are divided into small pieces and straightened and then fed into the cutting machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com