Method for realizing nanominiaturization of metal material surface crystal grain

A metal material, micro-nano technology, applied in the field of material processing, can solve the problems of high internal stress, unfavorable material corrosion resistance, large surface roughness of nano-layer, etc., and achieve the effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In this example, the typical and widely used hypoeutectoid 45# carbon steel is selected as the research material, and its chemical composition is C: 0.4~0.5wt / %, Si: ≤0.35wt / %, Mn: ≤0.40wt / %, S: ≤0.030wt / %, P: ≤0.035wt / %, the rest is iron.

[0017] After the sample is conventionally quenched and tempered (heated to 780°C for 30 minutes, water quenched, and tempered at 200°C for 5 hours), it is processed into a sample of 15mm×10mm×5mm, and cold rolled on a rolling mill by 30% to 50%. Then mechanically ground and polished to roughness R a ≈0.07μm, wash with acetone;

[0018] Place the sample in the above-mentioned high-current pulsed electron beam device, and evacuate to 10 -3 ~10 -4 Pa, and then electron beam bombardment treatment, the processing parameters are as follows: accelerating voltage 18 ~ 25kV, target source distance 80 ~ 160mm, magnetic field strength 800 ~ 1200Oe, energy density 3 ~ 5J / cm 2 , The number of pulses is 2 to 25 times, and the time interval of...

Embodiment 2

[0021] In this example, 316L stainless steel, a typical medical metal material, is selected as the research material, and its chemical composition is: C: 0.02wt%, Cr: 16-18wt%, Ni: 12-15wt%, Mn: 1.63wt%, Mo: 2wt%, Si 0.41wt%, P 0.02wt%, S: 0.03wt%, and the rest is iron.

[0022] The 316L steel sample is made into 20×10×4mm thin slices, which are cold rolled by 40% to 60% on a rolling mill, and the surface is ground and polished to roughness R a ≈0.07μm, washed with acetone;

[0023] Place the sample in the above-mentioned high-current pulsed electron beam device, and evacuate to 10 -3 ~10 -4 Pa, and then electron beam bombardment treatment, the processing parameters are as follows: accelerating voltage 20 ~ 25kV, target source distance 80 ~ 160mm, magnetic field strength 800 ~ 1200Oe, energy density 2 ~ 4J / cm 2 , The number of pulses is 2 to 25 times, and the time interval of each pulse is about 5 to 20s.

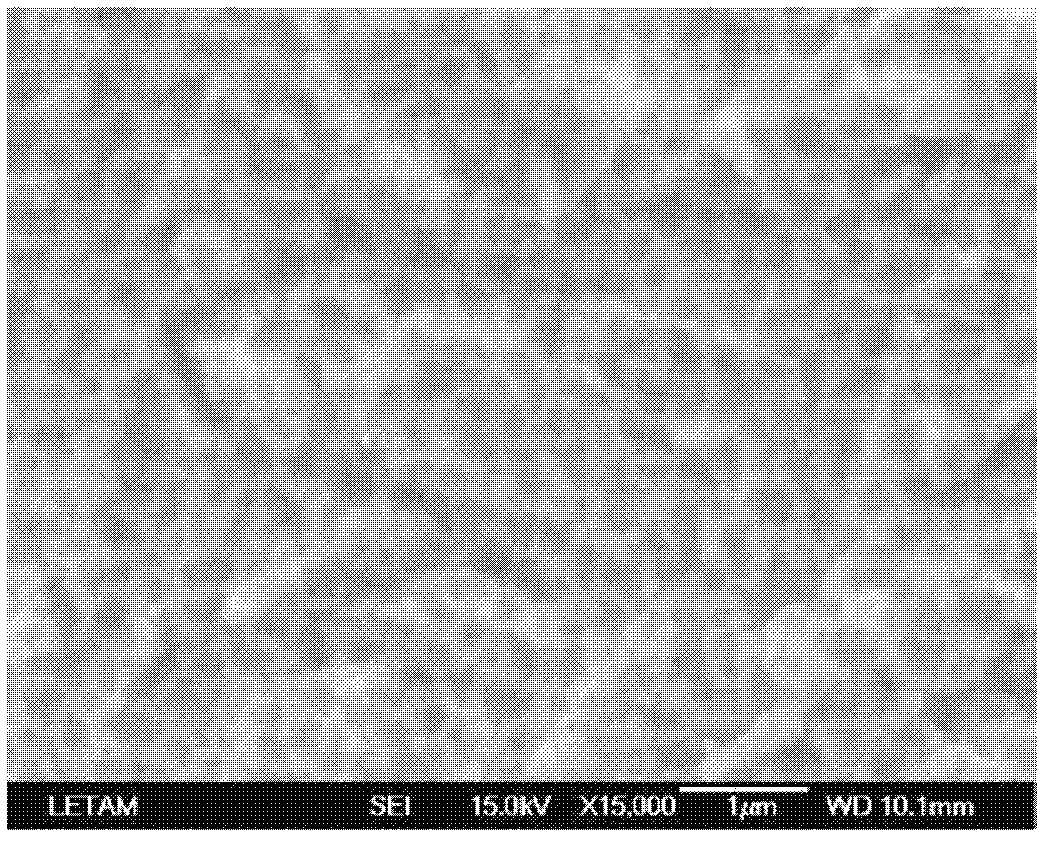

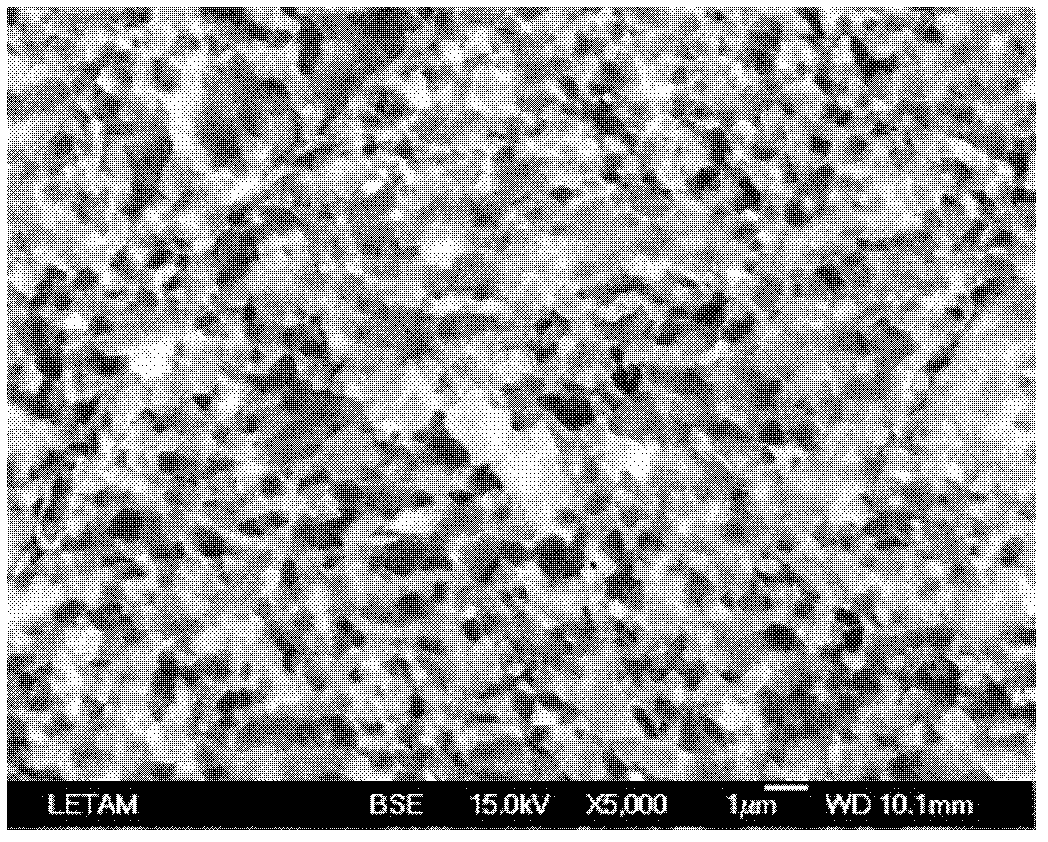

[0024] figure 2 It is the surface morphology of 316L stainless s...

Embodiment 3

[0026] In this embodiment, a typical and widely used medical alloy material NiTi alloy is selected as the research material, and its chemical composition is Ni: 50.6wt%, Ti: 49.4wt%.

[0027] The NiTi alloy sample is made into a 20×10×4mm thin sheet, which is cold rolled by 40% to 60% on a rolling mill, and the surface is ground and polished to a roughness of R a ≈0.07m, wash with acetone;

[0028] Place the sample in the above-mentioned high-current pulsed electron beam device, and evacuate to 10 -3 ~10 -4 Pa, and then electron beam bombardment treatment, the processing parameters are as follows: accelerating voltage 18 ~ 23kV, target source distance 80 ~ 160mm, magnetic field strength 800 ~ 1200Oe, energy density 2 ~ 4J / cm 2 , The number of pulses is 2 to 20 times, and the time interval of each pulse is about 5 to 20s.

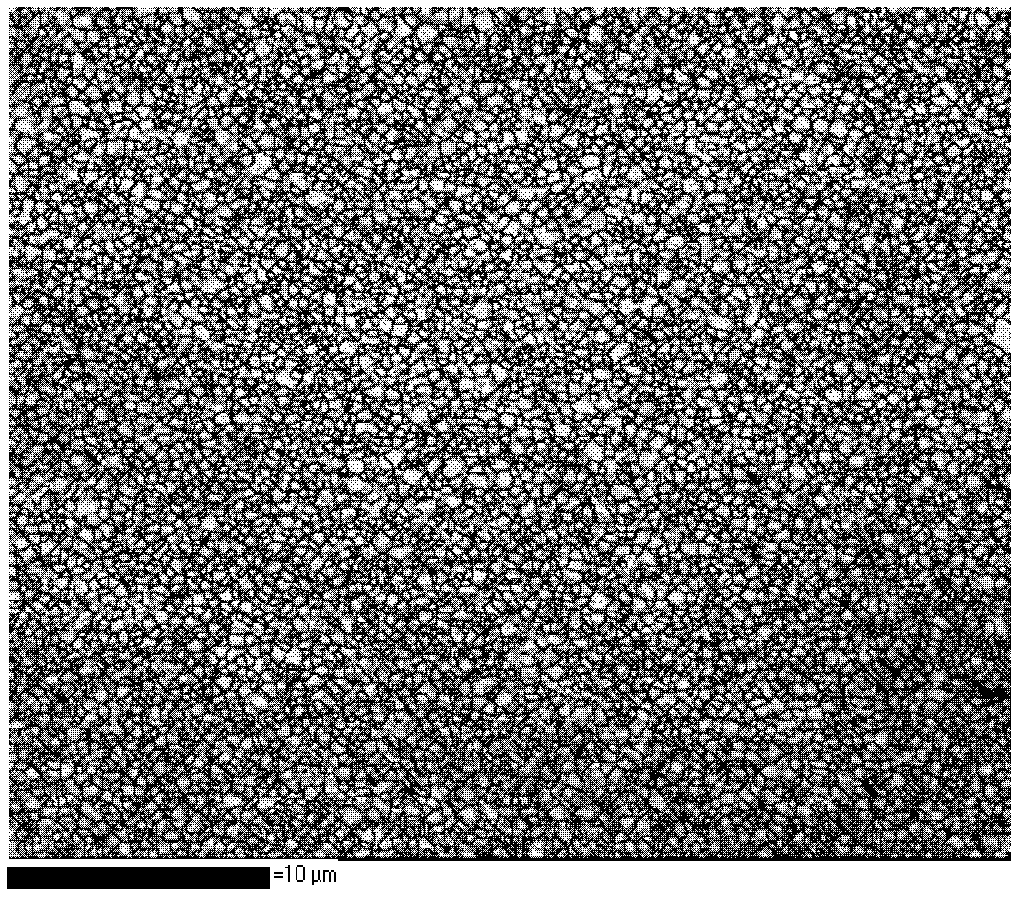

[0029] image 3 It is the surface backscattering diffraction morphology of the NiTi alloy sample after 5 pulse treatments. It can be clearly seen that f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com