Heat treatment reinforcement process for plasma arc

A technology of plasma arc and plasma arc, which is applied in the field of plasma arc heat treatment strengthening technology, can solve the problems of many production processes and high production costs, and achieve the effects of saving processes, increasing service life and increasing processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

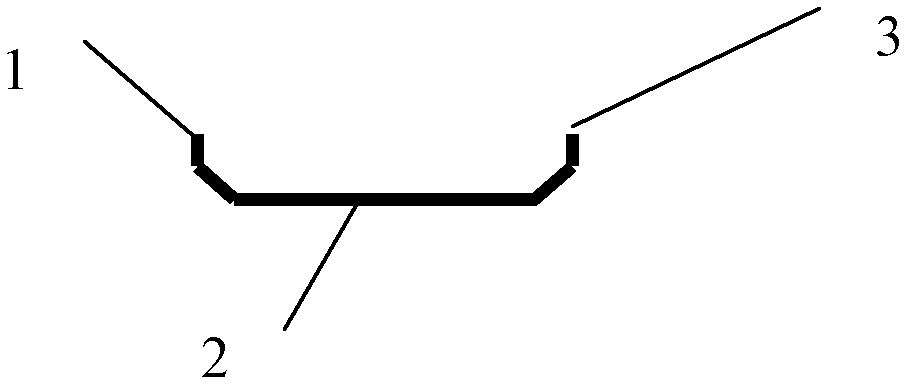

Image

Examples

Embodiment 1

[0026] For a wok with a 200 mm diameter rim, a nozzle diameter of 2.5 mm, a current of 25 amperes, a scanning speed of 28 mm / sec, a plasma arc length of 4.5 mm, and an argon flow rate of 0.3 cubic meters per minute are used for the wok. The pot is subjected to plasma arc heat treatment along the upper plane. The plasma arc makes the surface of the workpiece reach the melting temperature of the material. The heat treatment time is 30 seconds, and the crystal grains are refined by self-cooling to achieve surface quenching.

[0027] The pressure deformation test of the wok after the treatment shows that compared with the conventional treatment technology, the deformation resistance is equivalent, the heat treatment speed is increased by 30%, and the production cost is reduced. The surface hardness of the rim of the wok is HB=180, and the thickness of the surface hardening layer is 2 mm.

Embodiment 2

[0029] For a frying pan with a 250 mm diameter rim, a nozzle diameter of 3 mm, a current of 20 amperes, a scanning speed of 25 mm / sec, a plasma arc length of 4 mm, and an argon flow rate of 0.2 cubic meters per minute are used for the frying pan. The pot is subjected to plasma arc heat treatment along the upper plane. The plasma arc makes the surface of the workpiece reach the melting temperature of the material. The heat treatment time is 35 seconds, and the crystal grains are refined by self-cooling to achieve surface quenching.

[0030] The pressure deformation test is performed on the wok after the treatment. Compared with the conventional treatment technology, the deformation resistance is equivalent, the heat treatment speed is increased by 30%, and the production cost is reduced. The surface hardness of the rim of the wok is HB=150, and the thickness of the surface hardening layer is 0.5 mm.

Embodiment 3

[0032] For a wok with a 300 mm diameter rim, a nozzle diameter of 3 mm, a current of 30 amperes, a scanning speed of 40 mm / sec, a plasma arc length of 5 mm, and an argon gas flow rate of 0.5 cubic meters per minute are used for the wok. The pot is subjected to plasma arc heat treatment along the upper plane. The plasma arc makes the surface of the workpiece reach the melting temperature of the material. The heat treatment time is 40 seconds, and the crystal grains are refined by self-cooling to achieve surface quenching.

[0033] The pressure deformation test of the wok after the treatment shows that compared with the conventional treatment technology, the deformation resistance is equivalent, the heat treatment speed is increased by 30%, and the production cost is reduced. The surface hardness of the rim of the wok is HB=200, and the thickness of the surface hardening layer is 1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com