Growth method and equipment of sapphire crystal

A technology of sapphire crystal and growth method, which is applied in the field of crystal growth, can solve the problems of low processing efficiency and high wafer production cost, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

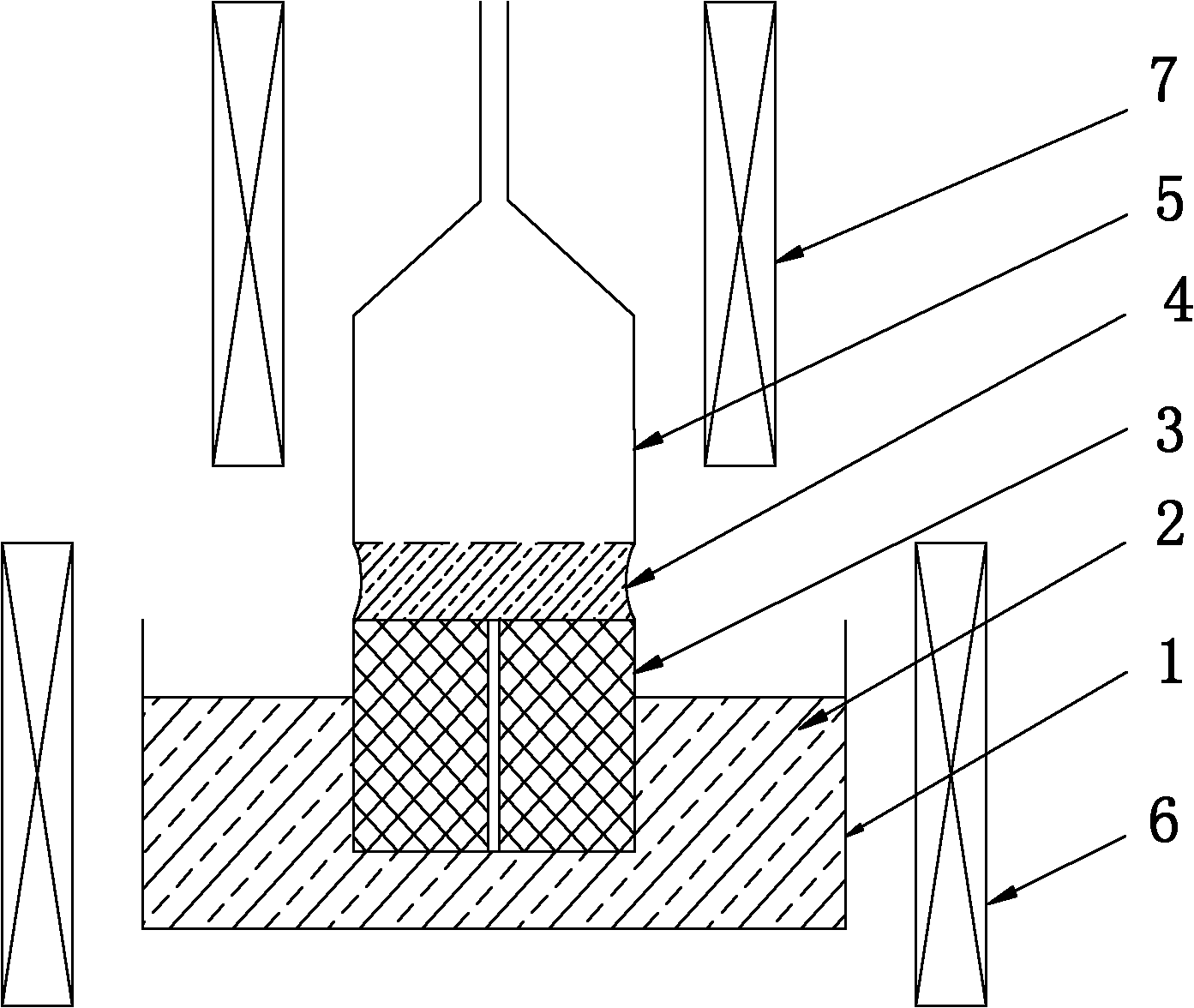

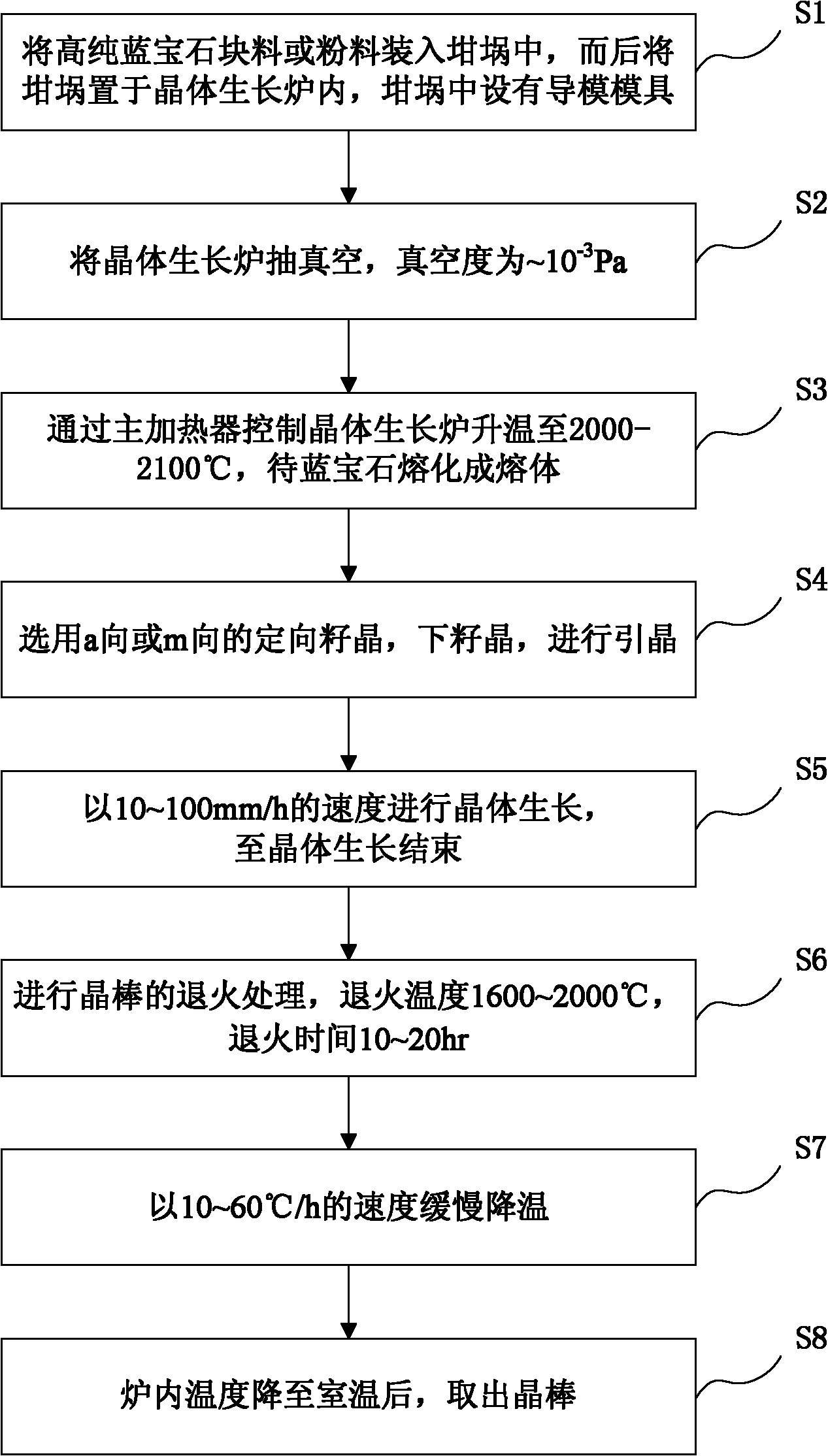

[0048] The present invention is a kind of growth method of sapphire rod-like crystal, selects high temperature resistance, and the material that has wettability to sapphire melt is used as guide mould, by carrying out structural design to this kind of material (as the top surface of mould has specific Shapes, such as square, rectangular, etc., use the capillary principle to guide the sapphire melt into its top surface; or use the edge of the mold to limit part of the melt) to ensure that it forms a melt film of a certain thickness or restricts a melt film of a certain thickness through it. A seed crystal with a certain crystal orientation is selected, and rod-shaped sapphire crystals are drawn from the melt film, and the drawn crystal rods meet the requirements of the LED and LD industries. The growth method of the present invention is called the TaVi method, which is an improved method based on TPS technology (Technique of Pulling from Shapers), and is a novel method for growi...

Embodiment 2

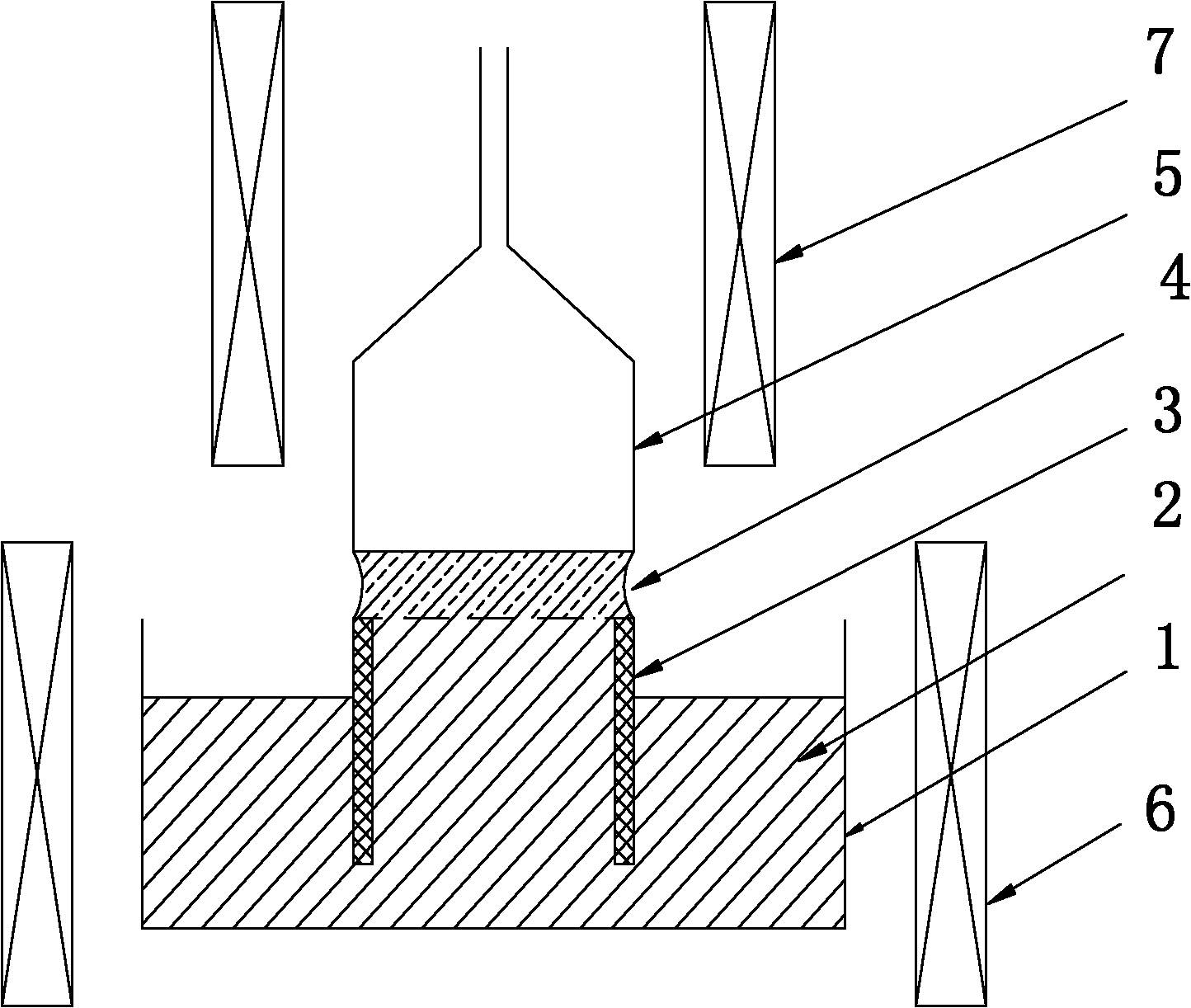

[0061] see figure 2 The difference between this embodiment and Embodiment 1 is that in this embodiment, the guide mold 3 is an annular mold with a square or rectangular cross-section; the material of the guide mold and the sapphire melt have a high-temperature-resistant material with wettability or its alloy material;

[0062] The difference between the growth method of the sapphire crystal of the present embodiment and the method described in the first embodiment is that in the third step of the present embodiment, part of the sapphire melt is confined in the annular guide mold 3, and the material of the guide mold 3 and the sapphire Wettability, the confined melt is pulled by the seed crystal with set crystal orientation, so as to grow rod-shaped crystals.

[0063] In summary, the sapphire crystal growth method and equipment proposed in the present invention can produce rod-shaped sapphire crystals, which can effectively improve the production efficiency of sapphire crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com