Preparation method of carboxylic acid betaine modified non-woven fabric for hemofiltration

A technology of blood filtration and non-woven fabrics, applied in the field of biomedical materials, can solve the problems of cumbersome cleaning process, high economic cost, and time-consuming, and achieve the effect of simple preparation process and good blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

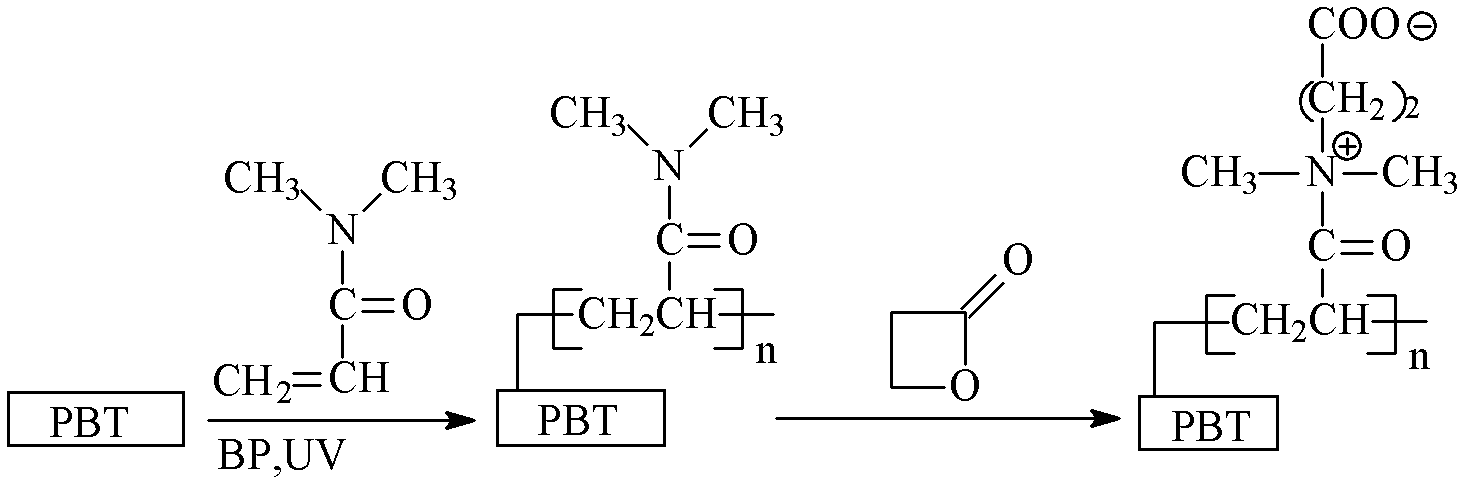

Method used

Image

Examples

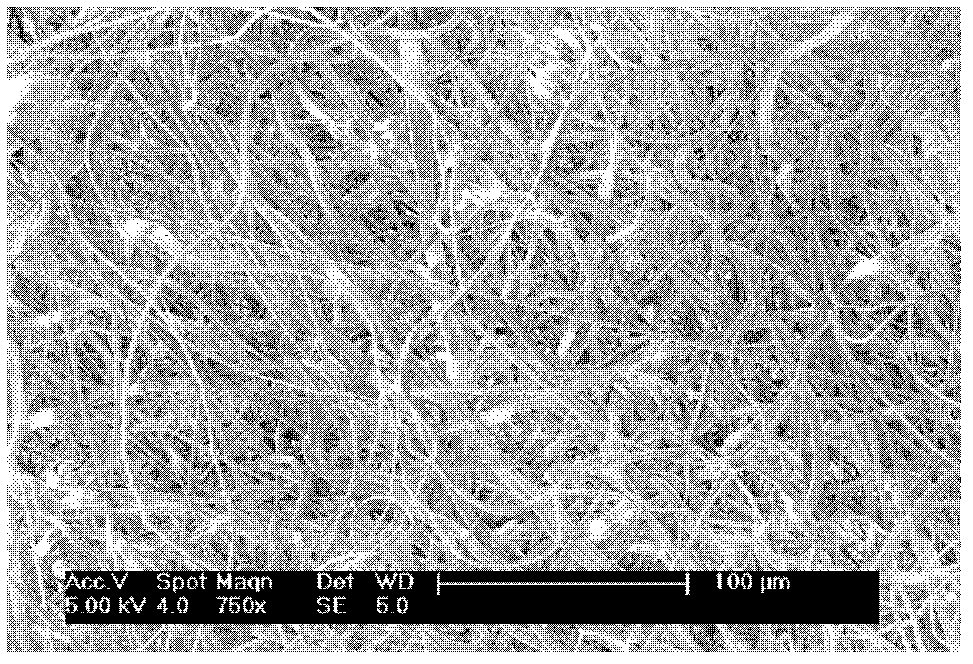

Embodiment 1

[0027] Set the areal density to 120g / m 2 , the average fiber diameter is 2.5 μm, the average pore size is 15 μm, the thickness is 1 mm, and the area is 10 × 10 cm 2 The PBT non-woven block was put into a 4% ethanol solution of photosensitizer benzophenone in 80 ml, soaked for 30 minutes, taken out and air-dried to obtain a non-woven fabric coated with photosensitizer on the surface. The non-woven fabric was immersed in 120ml of an aqueous solution of 20% DMAA, and passed through nitrogen for 30 minutes, and then the sample cell was put into an ultraviolet irradiation device with a nitrogen atmosphere to carry out ultraviolet irradiation grafting reaction, and the irradiation time was 30 minute. After the reaction, the non-woven fabric was taken out, placed in ethanol for ultrasonic cleaning for 30 minutes, and then washed with a large amount of water until the washing liquid had no foam and the surface of the non-woven fabric had no greasy feeling. The cleaned samples were p...

Embodiment 2

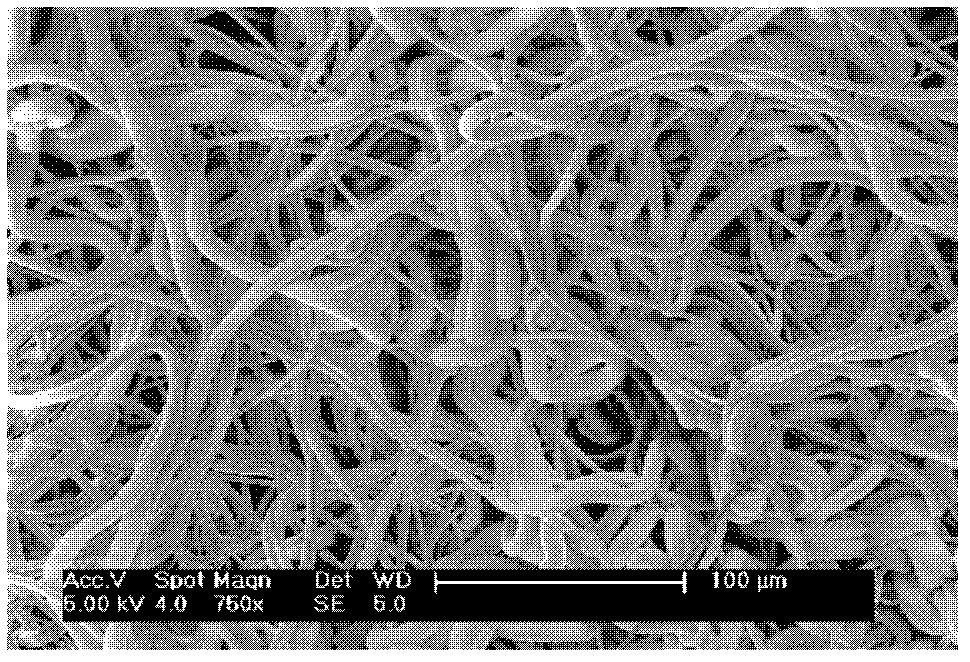

[0030] Set the areal density to 120g / m 2 , the average fiber diameter is 5 μm, the average pore size is 10 μm, the thickness is 1 mm, and the area is 10 × 10 cm 2 The PP non-woven fabric block was put into 4% 80ml ethanol solution of photosensitizer benzophenone, soaked for 30 minutes, taken out and air-dried to obtain a non-woven fabric coated with photosensitizer on the surface. The non-woven fabric was immersed in 120 ml of an aqueous solution of 25% DMAA, and passed nitrogen for 30 minutes, and then the sample cell was put into an ultraviolet irradiation device with nitrogen atmosphere to carry out ultraviolet irradiation grafting reaction, and the irradiation time was 45 minute. After the reaction, the non-woven fabric was taken out, placed in ethanol for ultrasonic cleaning for 30 minutes, and then washed with a large amount of water until the washing liquid had no foam and the surface of the non-woven fabric had no greasy feeling. The cleaned sample was placed in an o...

Embodiment 3

[0033] Set the areal density to 120g / m 2 , the average fiber diameter is 2.5 μm, the average pore size is 15 μm, the thickness is 1 mm, and the area is 10 × 10 cm 2The PBT non-woven block was put into a 4% ethanol solution of photosensitizer benzophenone in 80 ml, soaked for 30 minutes, taken out and air-dried to obtain a non-woven fabric coated with photosensitizer on the surface. The non-woven fabric was immersed in 120ml of an aqueous solution of 10% DMAA, and passed through nitrogen for 30 minutes, and then the sample cell was put into an ultraviolet irradiation device with a nitrogen atmosphere to carry out ultraviolet irradiation grafting reaction, and the irradiation time was 60 minute. After the reaction, the non-woven fabric was taken out, placed in ethanol for ultrasonic cleaning for 30 minutes, and then washed with a large amount of water until the washing liquid had no foam and the surface of the non-woven fabric had no greasy feeling. The cleaned samples were pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com