Control system and self-travelling type construction machinery with same

A technology of control system and steering control, which is applied in infrastructure engineering, processing of building materials, wellbore lining, etc. It can solve the problems of slow pumping displacement, inconvenient operation, and high cost, and achieve simple mechanism structure and easy operation. Simple, convenient and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

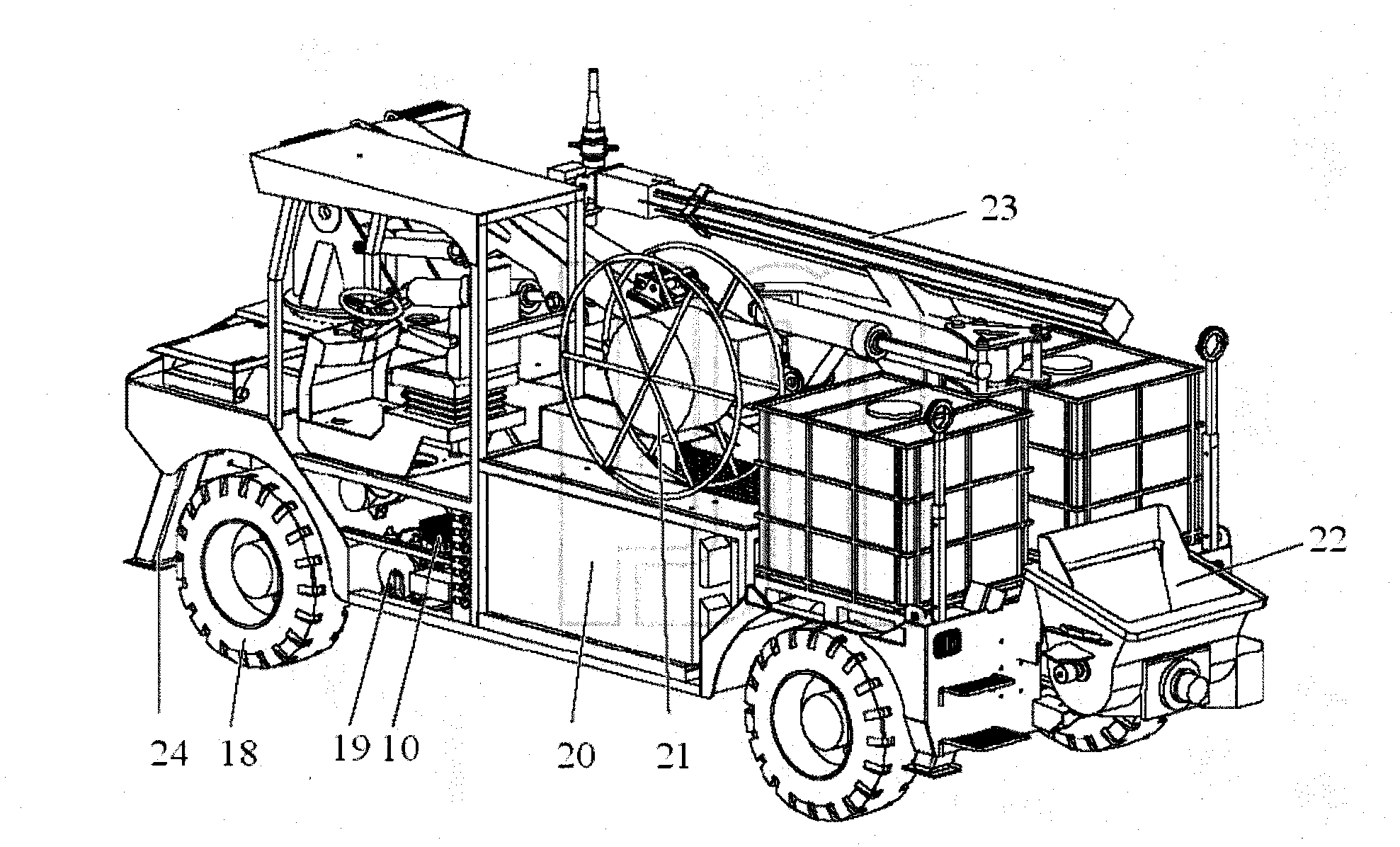

[0027] Such as figure 1 As shown, the present invention provides a kind of self-propelled construction machine, comprises mobile chassis 18, is provided with accelerator pump 19, high-pressure cleaning pump 10, air compressor system 20, cable tray device 21, concrete The pump 22 and the spray arm 23 are provided with support legs 24 below the mobile chassis 18, and the high-pressure cleaning pump 10, the cable tray device 21, the concrete pump 22, the spray arm 23 and the support legs 24 are controlled by the control system.

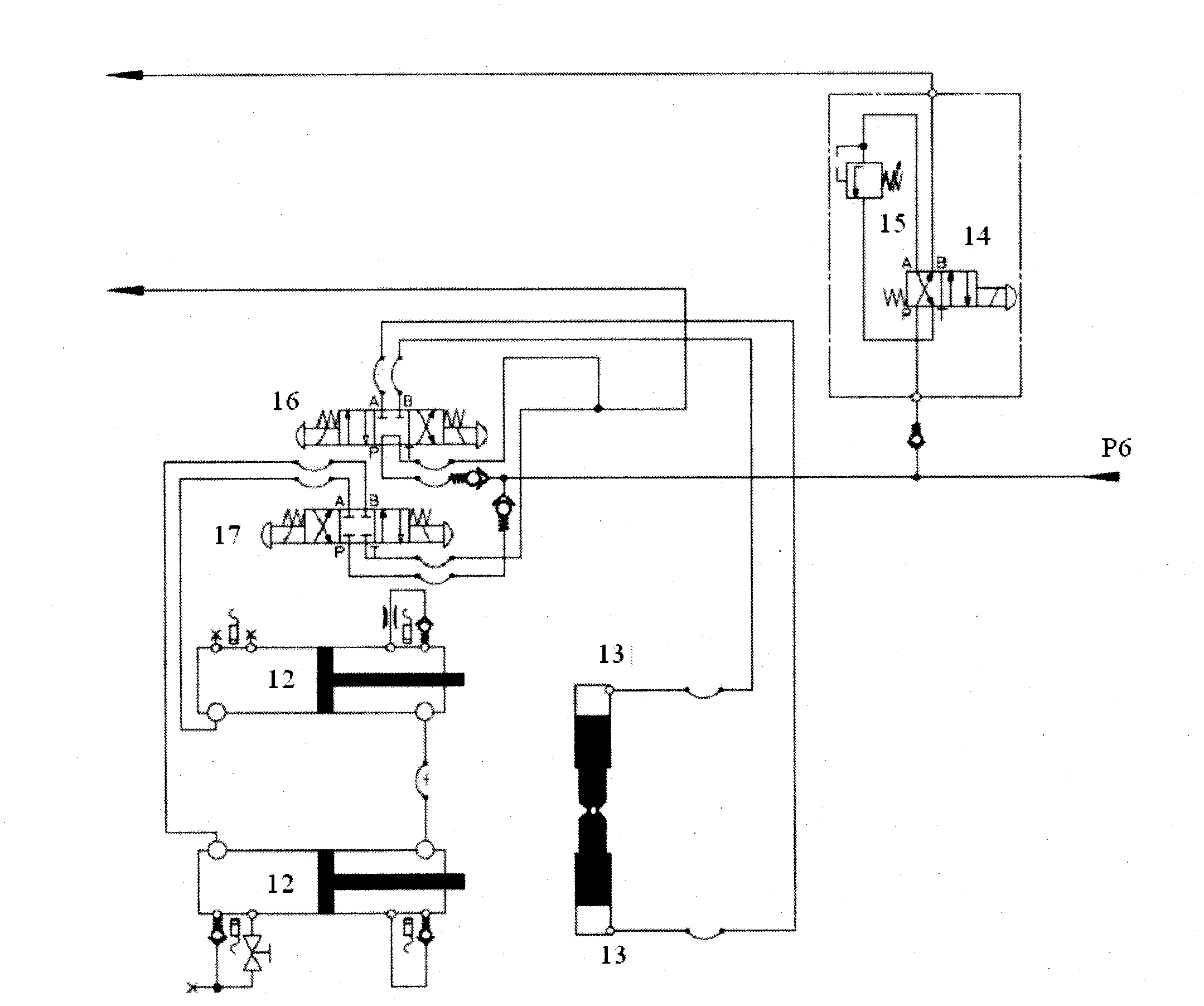

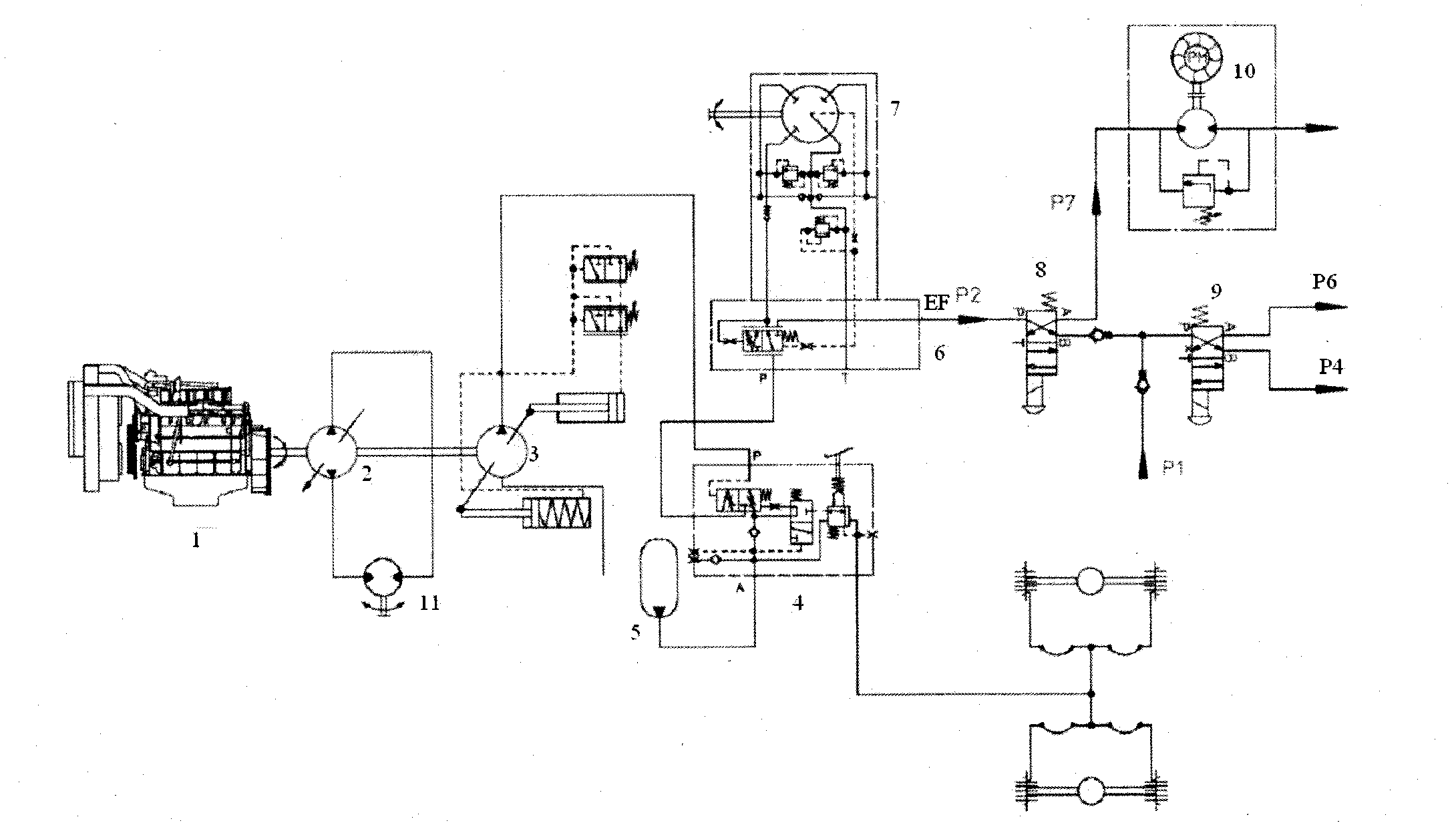

[0028] Such as figure 2 and image 3 As shown, the control system includes a concrete pump drive cylinder 12 and an S-valve swing valve cylinder 13, the concrete pump drive cylinder 12 and the S-valve swing valve cylinder 13 are connected to the concrete pump drive cylinder reversing solenoid valve 17 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com