Rail pressure control method for gasoline direct injection engine common rail fuel system

A fuel system and control method technology, applied in engine control, fuel injection control, electrical control, etc., can solve the problem of increasing the difficulty of adjusting control algorithm parameters, heavy workload, and lack of detailed consideration of the structure and characteristics of the common rail fuel system And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

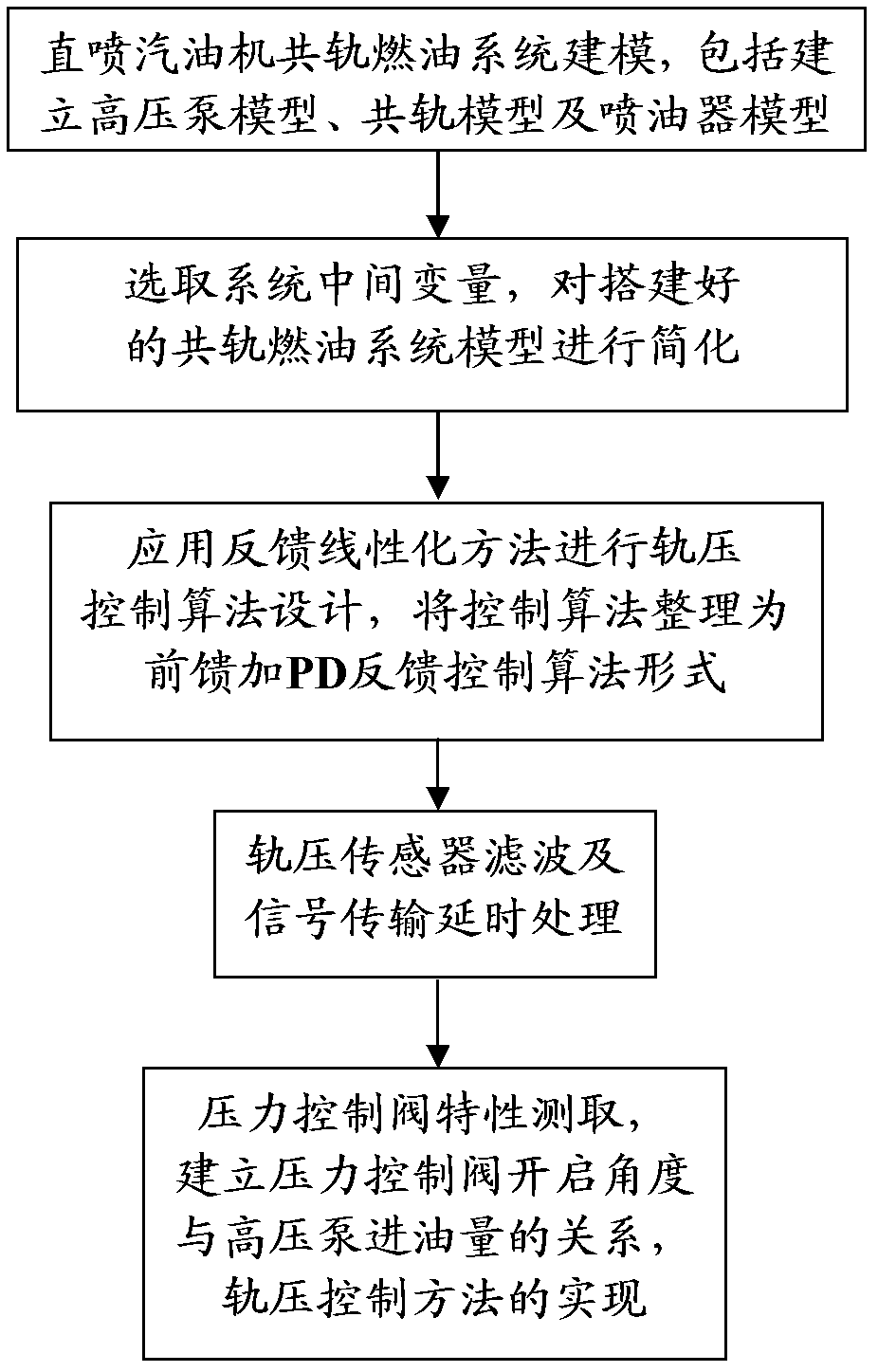

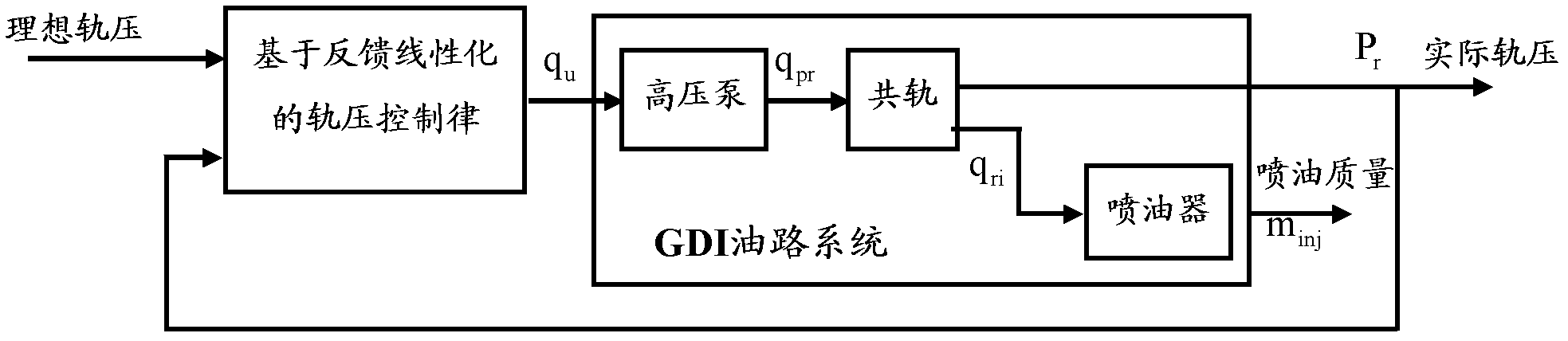

Method used

Image

Examples

Embodiment Construction

[0062] The present invention is described in detail below in conjunction with accompanying drawing:

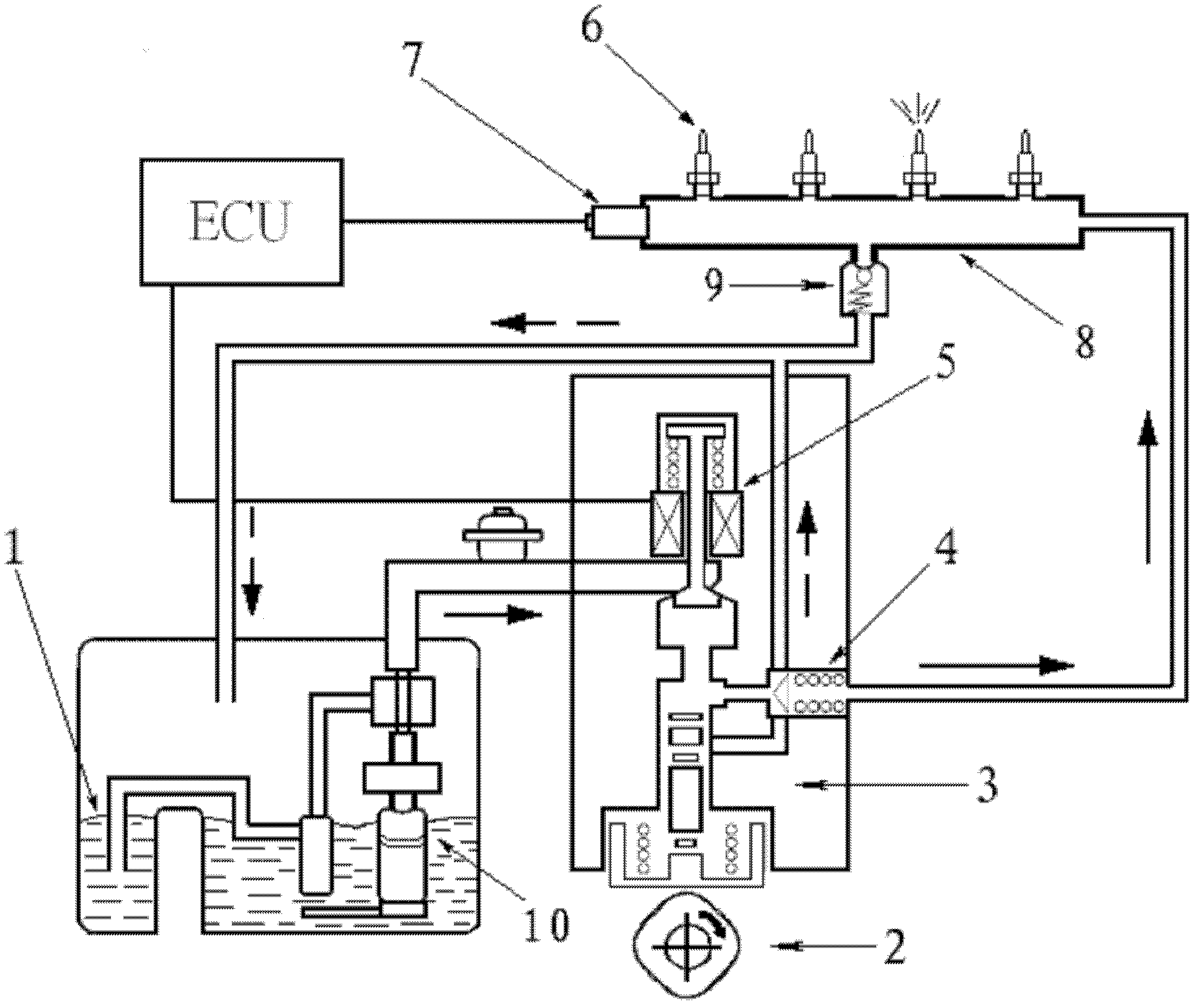

[0063] refer to figure 2 , The invention provides a rail pressure control method for a common rail fuel system of a direct injection gasoline engine, which can achieve a better rail pressure control effect. The common rail fuel system is the most important part of the fuel supply system of the direct injection gasoline engine. Better fuel injection effect can also be obtained at low speeds. The basic structure of the direct injection gasoline engine common rail fuel system includes fuel tank 1, cam 2, high pressure pump 3, check valve 4, pressure control valve 5, fuel injector 6, rail pressure sensor 7, common rail 8, pressure limiting valve 9, Low-pressure electric fuel pump 10 and electronic control unit ECU.

[0064] The common rail fuel system of a direct injection gasoline engine is quite different from that of a traditional port injection engine. 2 The fuel oil flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com