MEMS (Micro Electro Mechanical System) capacitor based on three-dimensional silicon micro structure and manufacturing method thereof

A manufacturing method and capacitor technology, applied in capacitors, microstructure technology, fixed capacitors, etc., can solve the problems of low overload resistance, small capacity-to-volume ratio, poor environmental adaptability, etc., and achieve high safety, high energy storage density, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

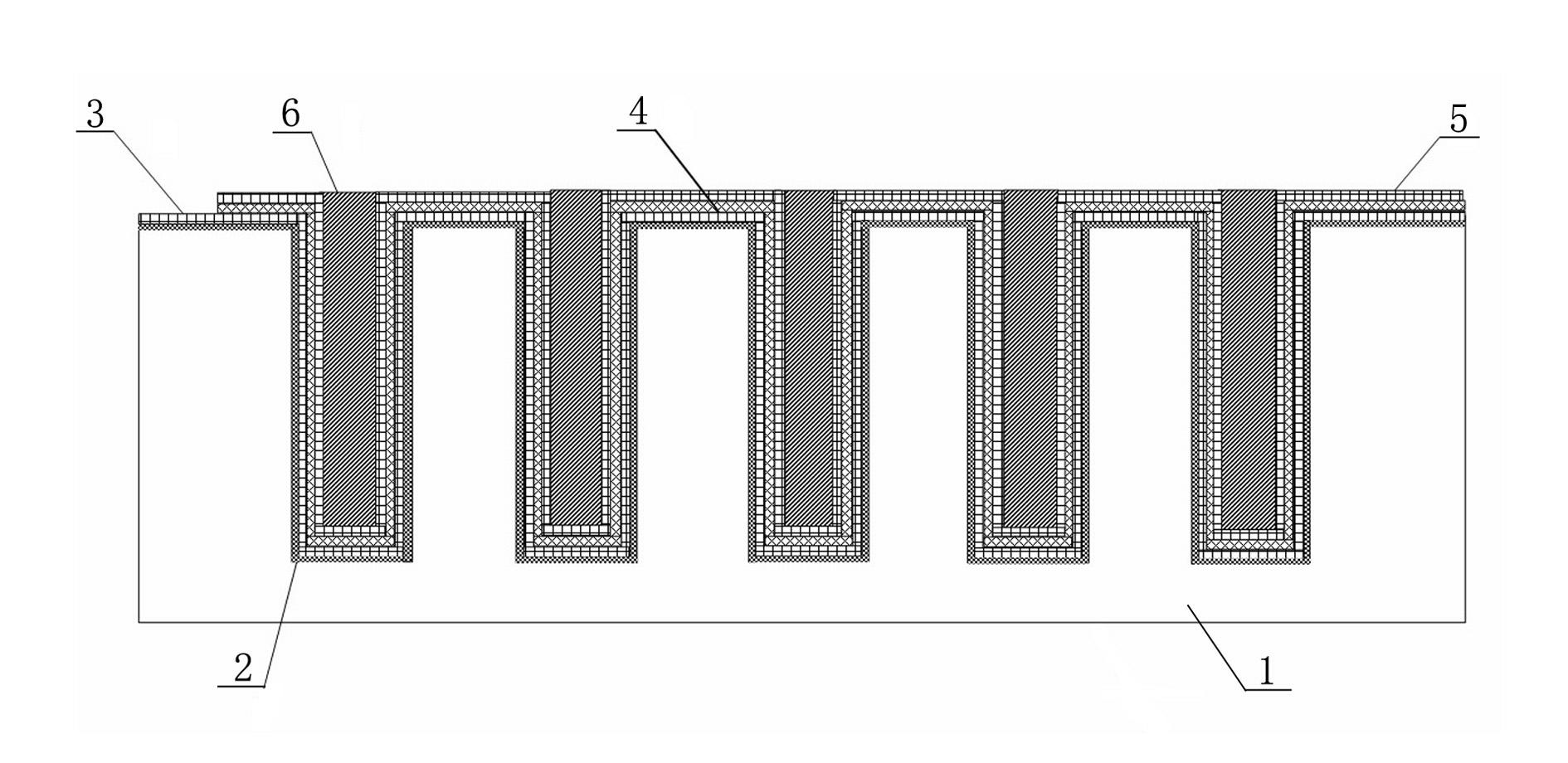

[0017] A MEMS capacitor based on a three-dimensional silicon microstructure, comprising a silicon substrate 1; the upper surface of the silicon substrate 1 is processed with a three-dimensional deep groove structure 7 with a large specific surface area; the upper surface of the silicon substrate 1 and the inner cavity surface of the three-dimensional deep groove structure 7 with a large specific surface area are formed There is an electrical insulating layer 2; a lower electrode layer 3 is formed on the upper surface of the electrical insulating layer 2; a dielectric layer 4 is formed on the upper surface of the lower electrode layer 3; an upper electrode layer 5 is formed on the upper surface of the dielectric layer 4; the lower electrode layer 3 is partially exposed to Outside the upper electrode layer 5; the micropores of the three-dimensional deep groove structure 7 with a large specific surface area are filled with a filling layer 6;

[0018] The material of the silicon su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com