Negative electrode active material, preparation method thereof, and lithium ion battery

A negative electrode active material, lithium ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unsatisfactory electrochemical performance, unsatisfactory lithium ion battery, poor cycle stability, etc., and achieve good Application prospect, stable cycle performance, good electrical conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The embodiment of the present invention provides a kind of preparation method of lithium ion negative electrode active material, it comprises the following steps:

[0021] S1, potassium permanganate (KMnO 4 ) mixed with hydrogen chloride (HCl) in water to form a solution; and

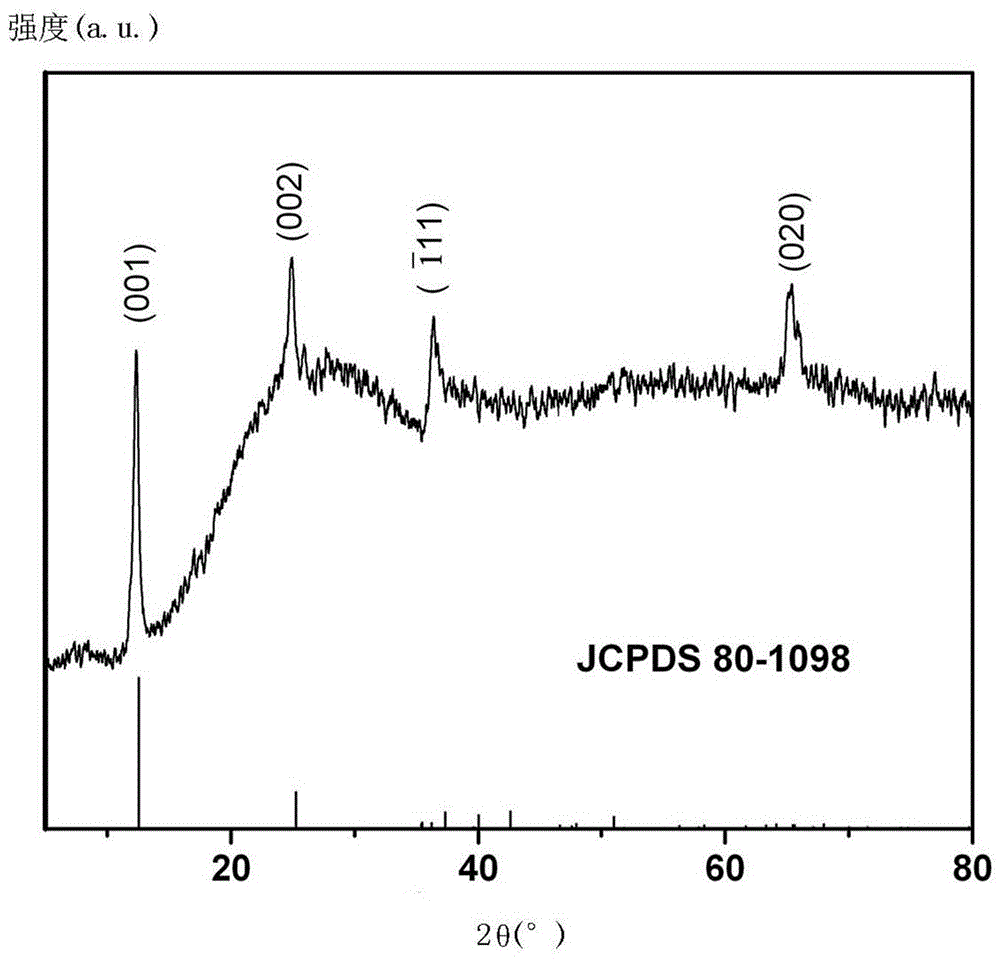

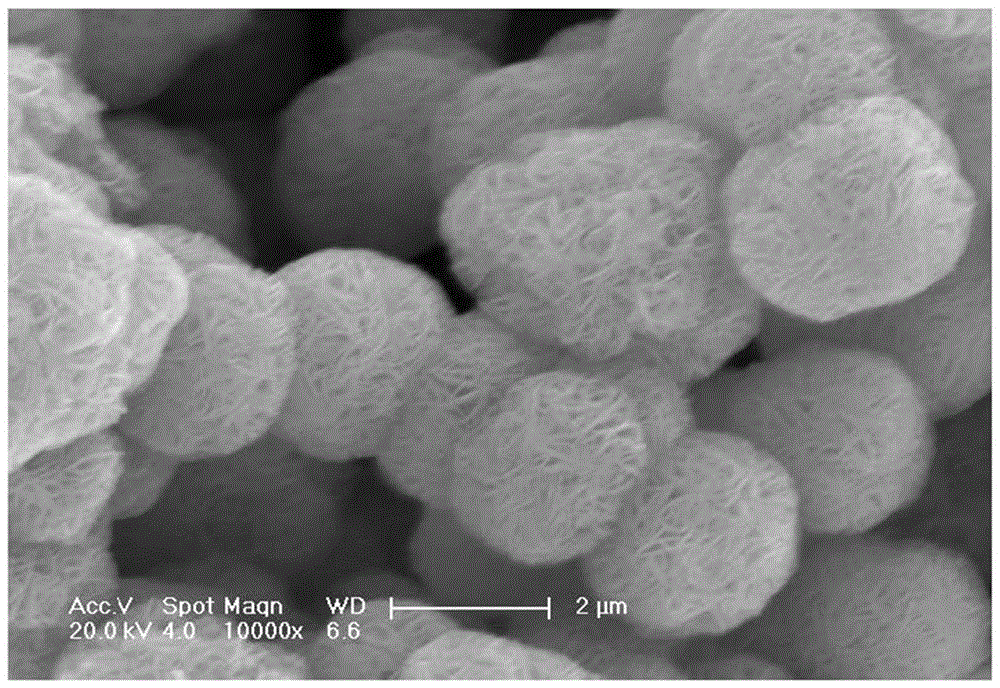

[0022] S2, the solution is subjected to a hydrothermal reaction in a hydrothermal kettle, the reaction temperature is 120°C~160°C, and the holding time is 0.5h~2h to generate MnO 2 secondary ball.

[0023] Specifically, in this step S1, potassium permanganate can be dissolved in water to configure a potassium permanganate solution, and then the potassium permanganate solution is mixed with a hydrochloric acid solution to form the solution, and the concentration of the hydrochloric acid used is greater than 36%. The solution is only composed of potassium permanganate, HCl and water, and does not contain other additives such as surfactants. In this solution, the molar ratio of potassium permang...

Embodiment 1

[0030] 1 millimolar (mmol) KMnO 4 and 4 mmol HCl (36% concentrated hydrochloric acid) were dissolved in 45 ml deionized water to form a solution. The solution was then transferred to a 65 ml volume hydrothermal kettle liner. Heat the sealed hydrothermal kettle to 140°C and keep it warm for 2 hours. After the completion of the reaction, the hydrothermal kettle was naturally cooled to room temperature, and the black precipitate in the kettle was collected, centrifugally washed with deionized water to remove impurity ions, and then dried in air to obtain MnO 2 secondary ball.

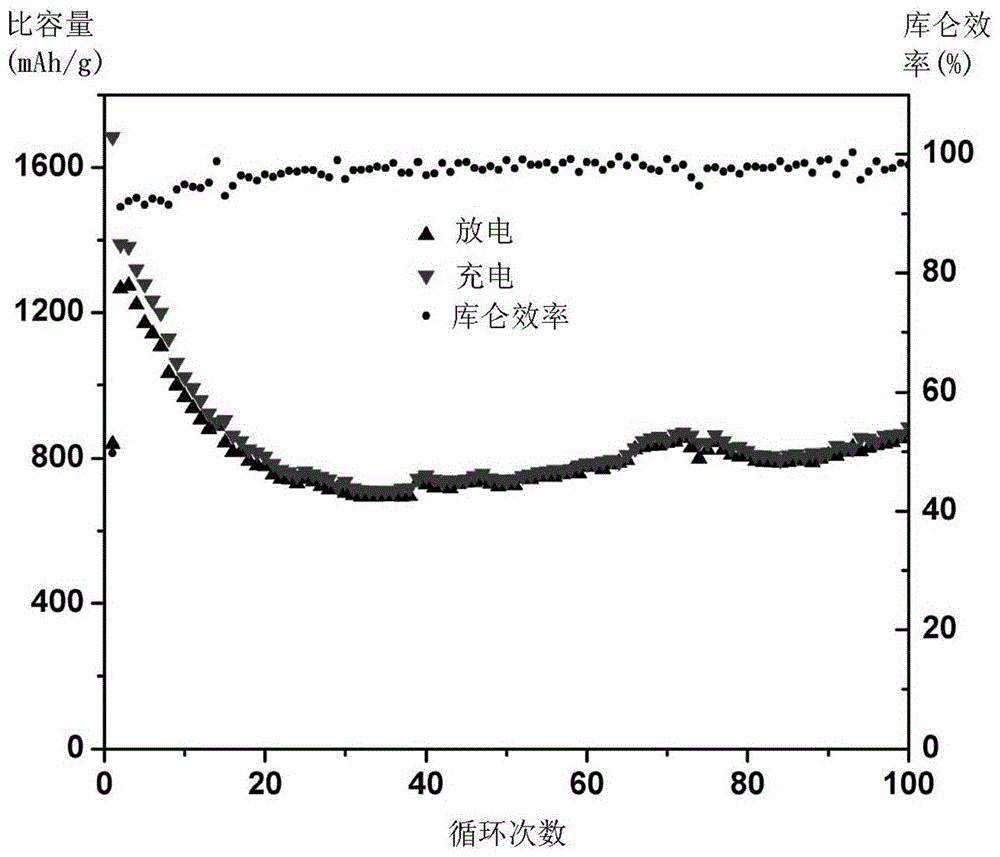

[0031] MnO 2 The secondary ball is used as the negative electrode active material of the lithium ion battery to make the negative electrode sheet. The specific process is: MnO 2 The secondary ball and the conductive agent acetylene black are mixed evenly, and then the binder SBR / CMC is added to make a slurry, which is evenly coated on the copper foil, dried and cut into negative pole pieces. MnO 2 , ...

Embodiment 2

[0034] 1 mmol KMnO 4 and 10 mmol HCl (36% concentrated hydrochloric acid) were dissolved in 45 ml deionized water to form a solution. The solution was then transferred to a 65 ml volume hydrothermal kettle liner. Heat the sealed hydrothermal kettle to 120°C and keep it warm for 2 hours. After the completion of the reaction, the hydrothermal kettle was naturally cooled to room temperature, and the black precipitate in the kettle was collected, centrifugally washed with deionized water to remove impurity ions, and then dried in air to obtain MnO 2 secondary ball.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com