Nitride semiconductor laser

A technology of nitride semiconductors and lasers, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve problems that affect the work and life of lasers, uneven cavity surfaces of lasers, and enhanced cavity surface absorption, etc., to achieve simple structure and easy preparation, stress-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

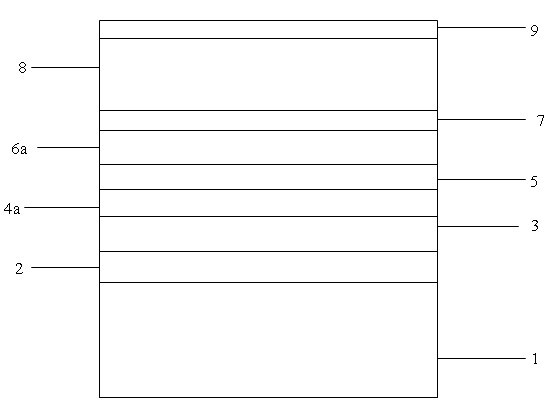

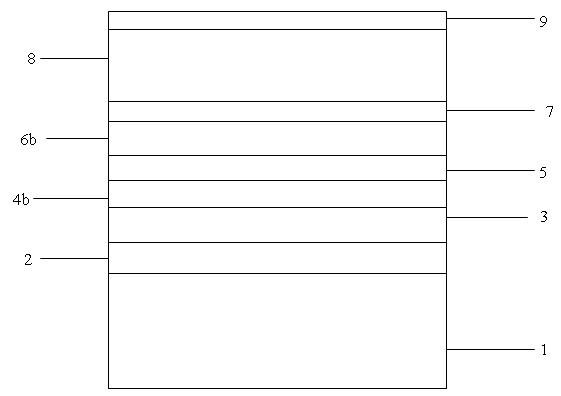

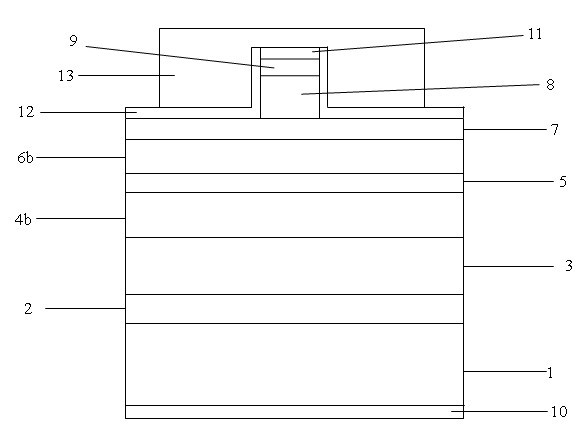

[0024] see Figure 2~4 As shown, a nitride semiconductor laser adopts a GaN-based blue laser, which is grown on a self-supporting GaN substrate 1 by MOCVD as figure 2 Structure shown, 2um thick n-GaN layer 2, 1um thick n-Al 0.16 Ga 0.84 N / GaN superlattice confinement layer 3, 140nm thick n-In x Ga 1-x N lower waveguide layer 4b, its In composition x linearly changes from 0 to 0.06, 5 cycles of In 0.17 Ga 0.83 N / n-GaN multi-quantum well active region 5, the well layer is not doped, the thickness is 2nm, the barrier layer is n-type doped, the thickness is 8nm, 100nm undoped gradient In y Ga 1-y N upper waveguide layer 6b, its In composition linearly changes from 0.06 to 0, 20nm thick p-Al 0.2 Ga 0.8 N electron blocking layer 7, 600nm thick p-Al 0.16 Ga 0.84 N / GaN optical confinement layer 8, p-GaN contact layer 9 with a thickness of 20nm.

[0025] After the epitaxial wafer is grown in MOCVD, rapid annealing is carried out in a nitrogen atmosphere of 800 °C for 20 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com