Method for precisely carrying out hot forging on driven spiral bevel gear of automobile rear axle

A technology of spiral bevel gears and automobile rear axles, which is applied to vehicle parts, railway car body parts, forging/pressing/hammer devices, etc., can solve the problems of low material utilization rate, complicated process, and low mold life, and achieve material The effect of high utilization rate, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

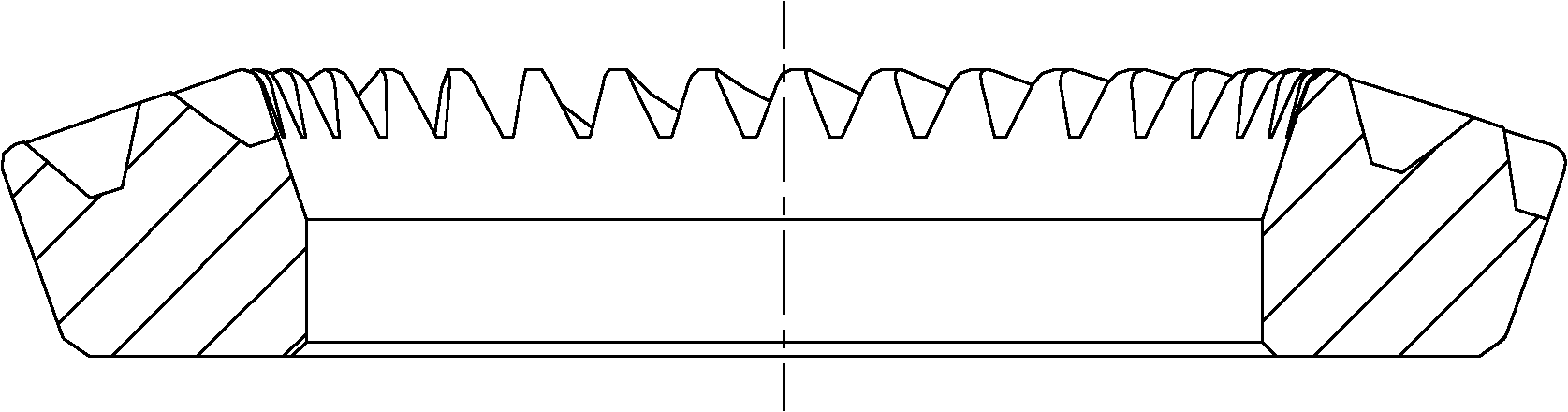

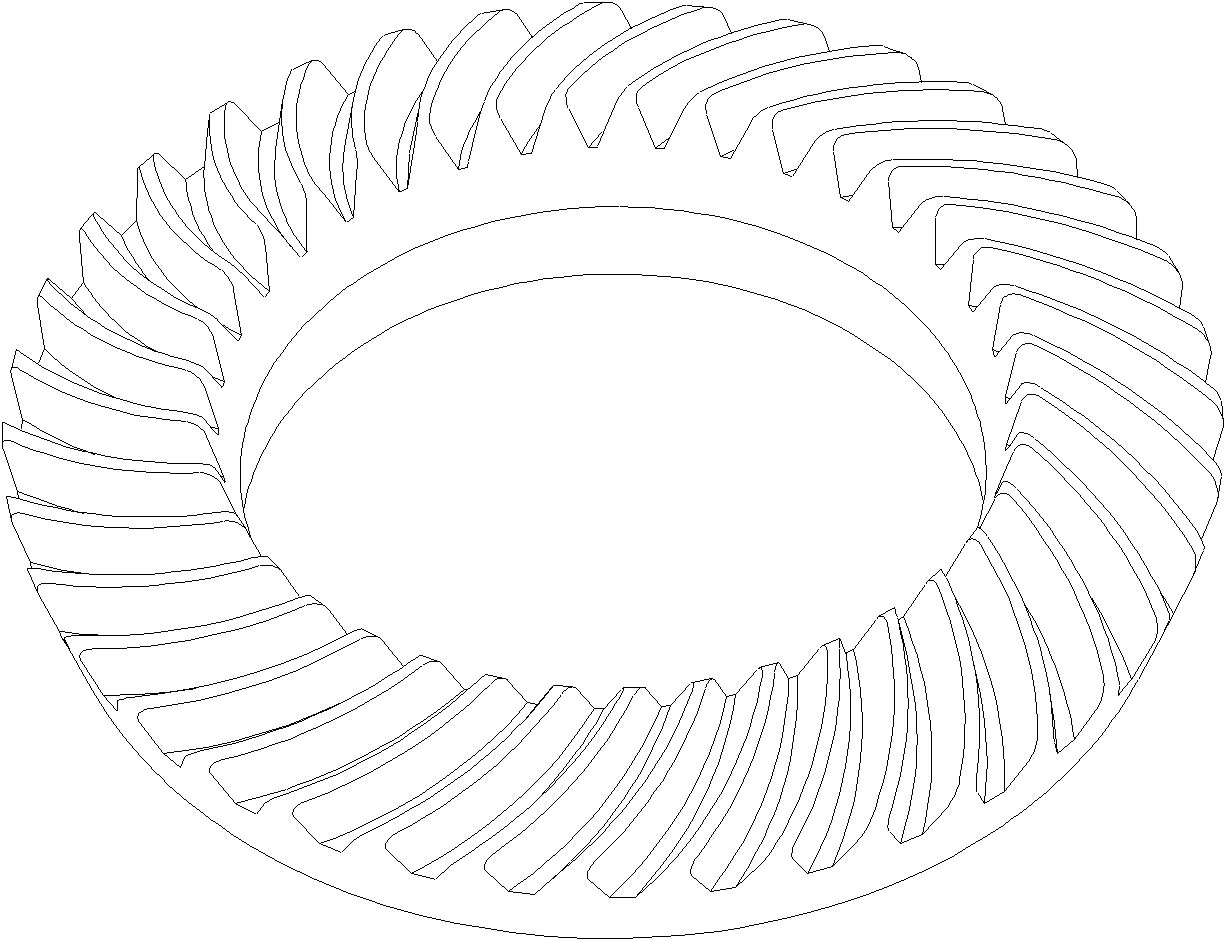

[0032] A driven spiral bevel gear for an automobile rear axle ( figure 1 , figure 2 ) The method of precision hot forging is carried out according to the following steps:

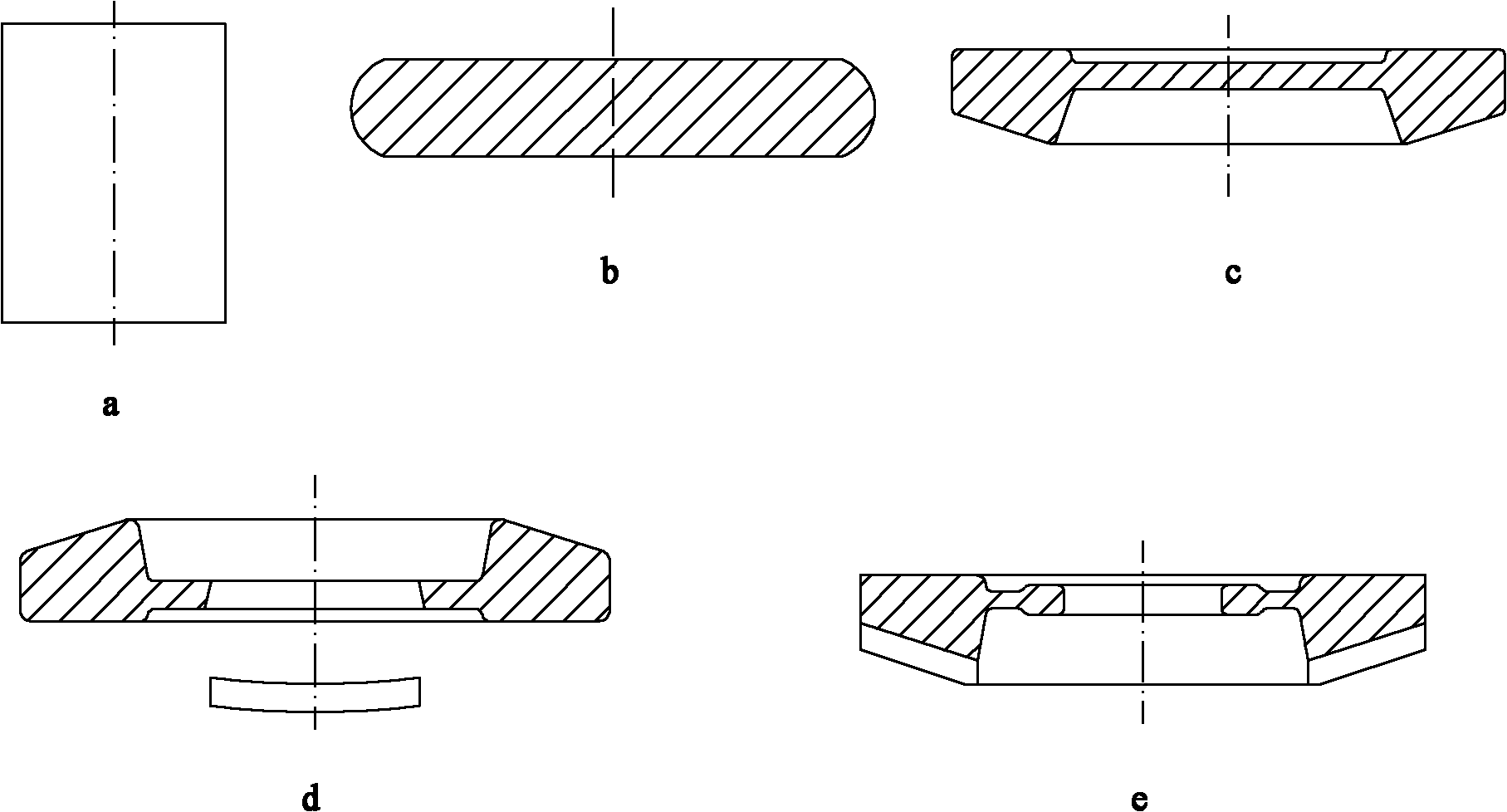

[0033] (1) First design the shape of each forming step of the forging, calculate the size of the bar based on the principle of equal volume, ensure a suitable height-to-diameter ratio, and then turn the cylindrical bar ( image 3 a), the oxide skin on the surface of the blank can be turned off first to improve the blanking accuracy.

[0034] (2) Heat the rolled bar to 1100-1200°C, take it out and put it under the press for upsetting, and upsetting into a round cake-shaped upsetting piece ( image 3 b).

[0035] (3) Put the upsetting piece into the pre-forging die and forge it into a pre-forging with upper and lower blind holes ( image 3 c), the pre-forging is ring-shaped, the shape is close to the final forging, the difference is that there is no tooth shape.

[0036] (4) Take out the pre-forging and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com