Laser welding device

A technology of laser welding and equipment, which is applied in the direction of laser welding equipment, welding equipment, laser devices, etc., can solve the problems of inability to absorb the effective part of the laser beam, poor welding structure, material spatter, etc., and achieve improved welding efficiency and welding quality, easy The effect of absorbing and avoiding material splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereto.

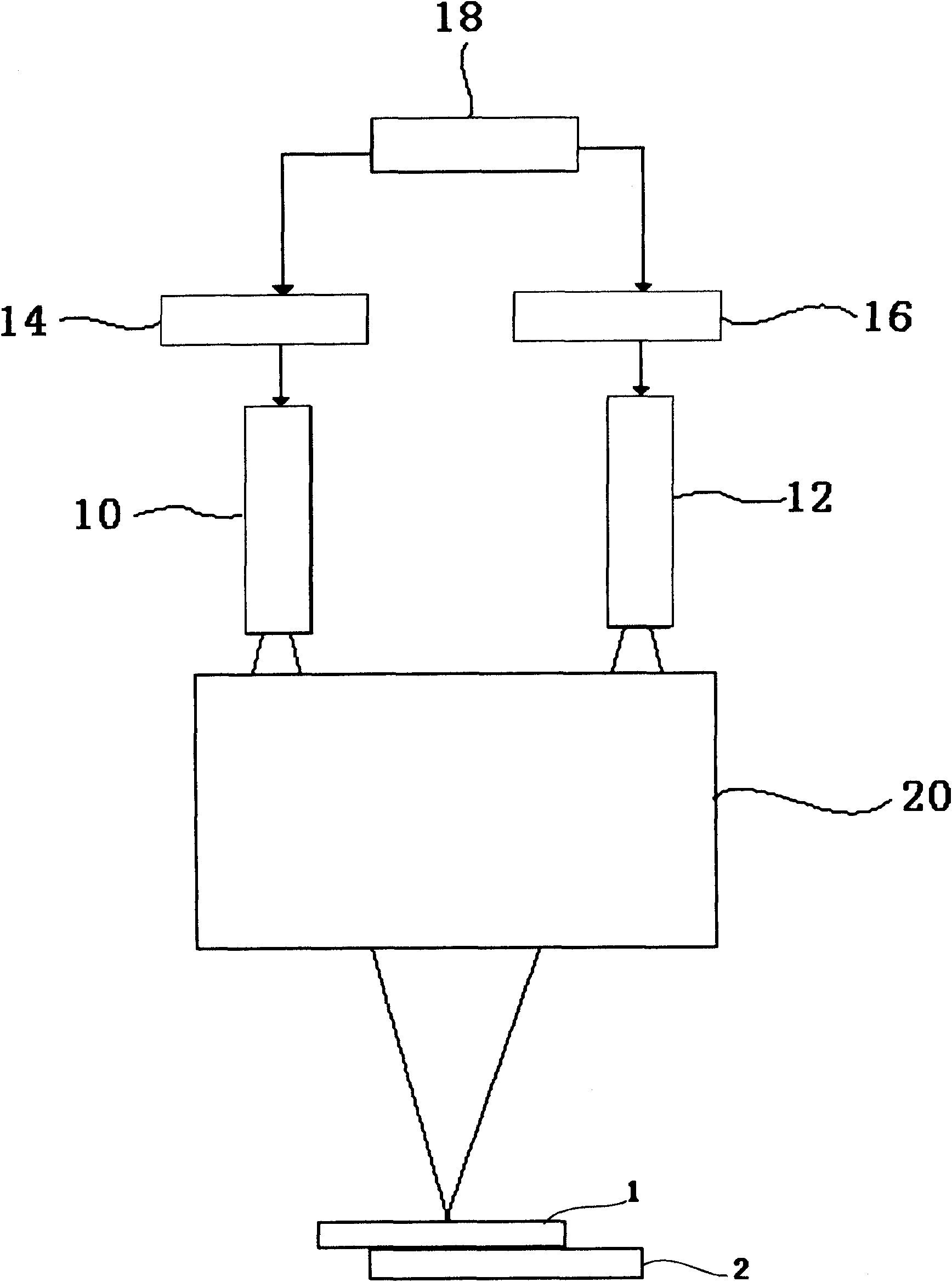

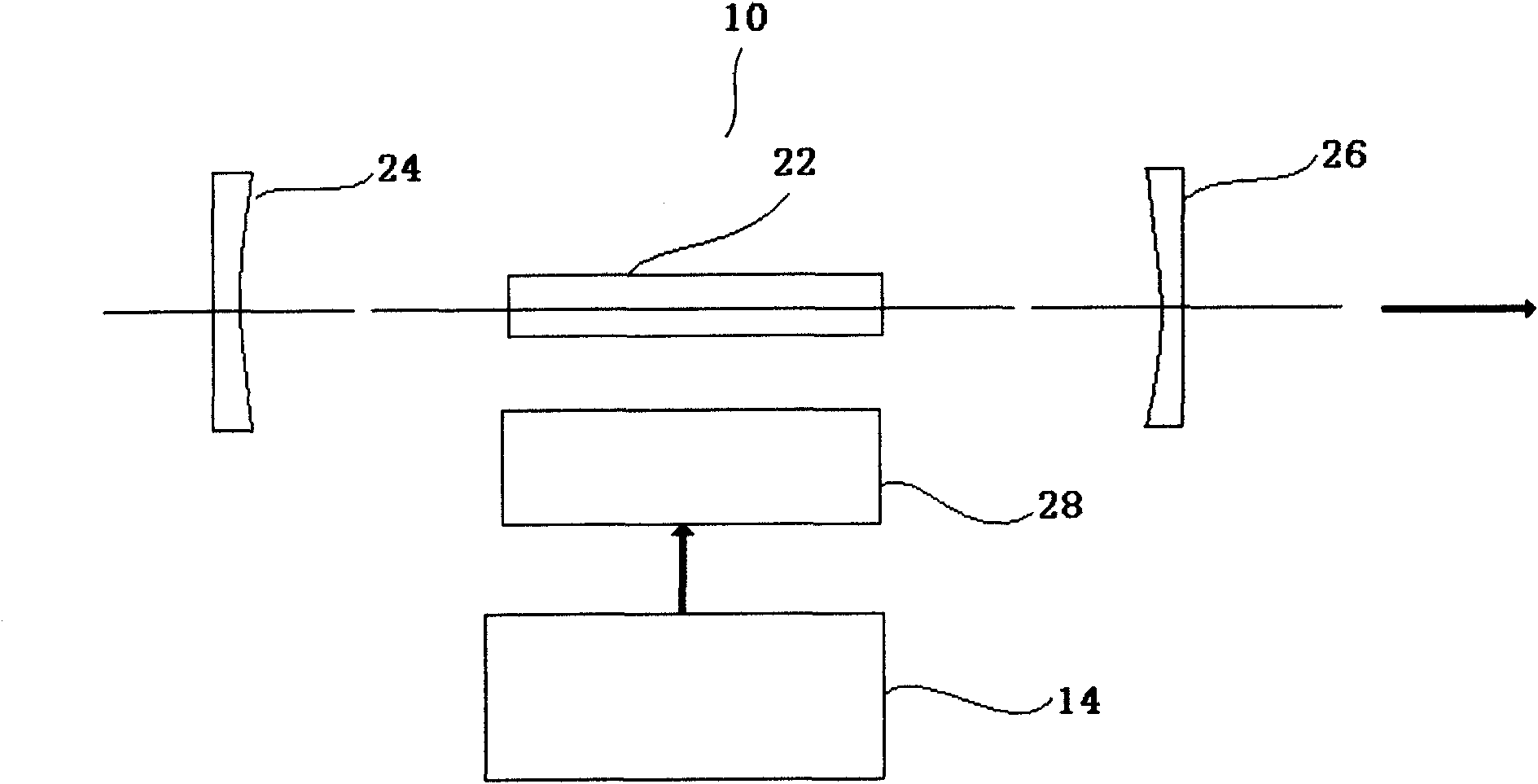

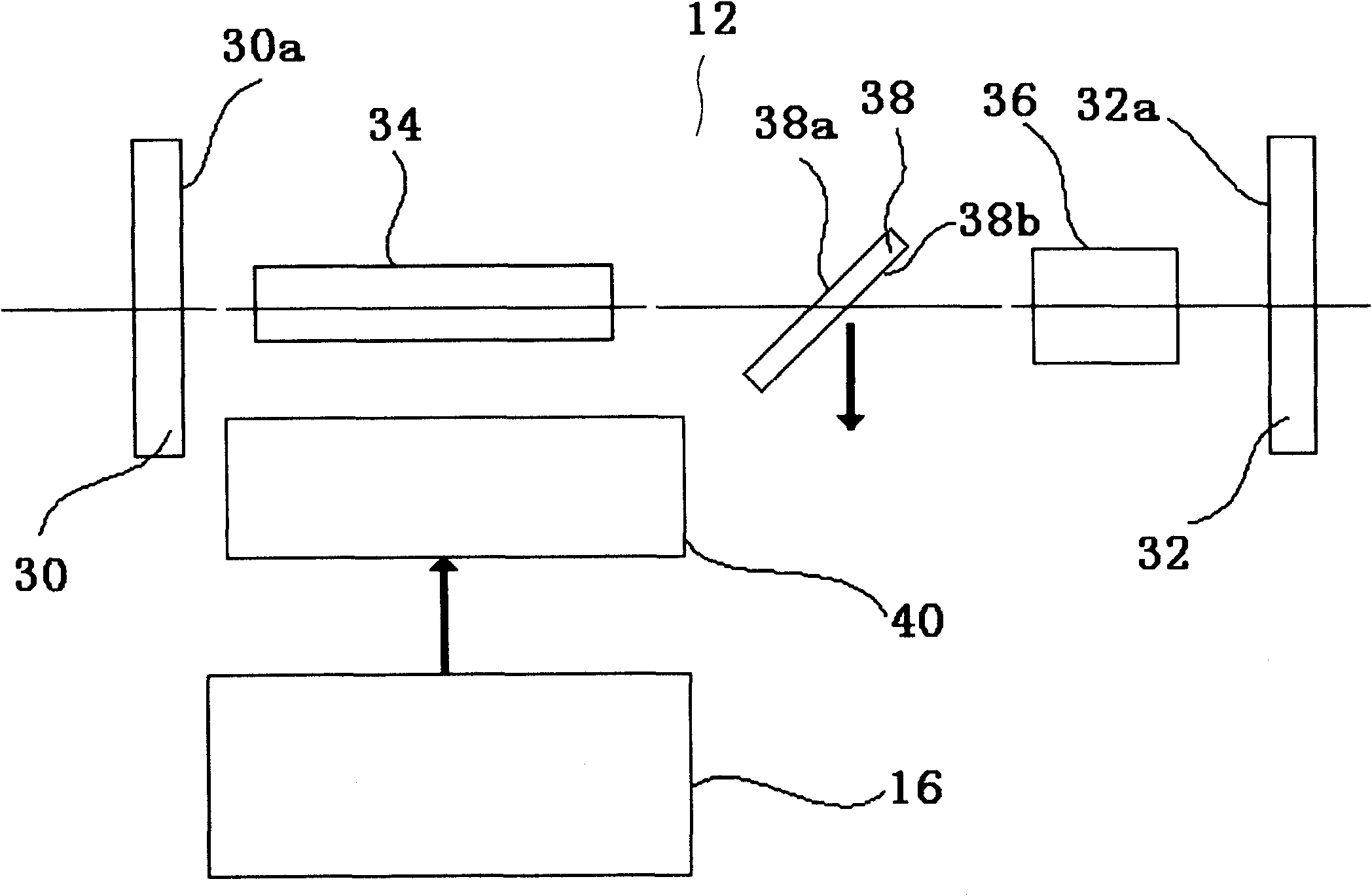

[0018] figure 1 It is a simplified block diagram of laser welding equipment that couples and focuses two laser beams with different wavelengths according to an embodiment of the present invention. The laser welding equipment includes: Nd:YAG fundamental wave resonator 10 and Nd:YAG harmonic resonator 12, which are used to generate fundamental wave and harmonic respectively; laser power supply 14 of fundamental wave resonator and laser power supply of harmonic resonator 16, respectively connected with the electro-optical pumping device on the fundamental wave resonator 10 and the harmonic resonator 12; the control unit 18 is used to control the laser power supply 14 of the fundamental wave resonator and the laser power supply 16 of the harmonic res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com