Preparation method for multielement dissymmetrical microsphere and heterogeneous microsphere shell

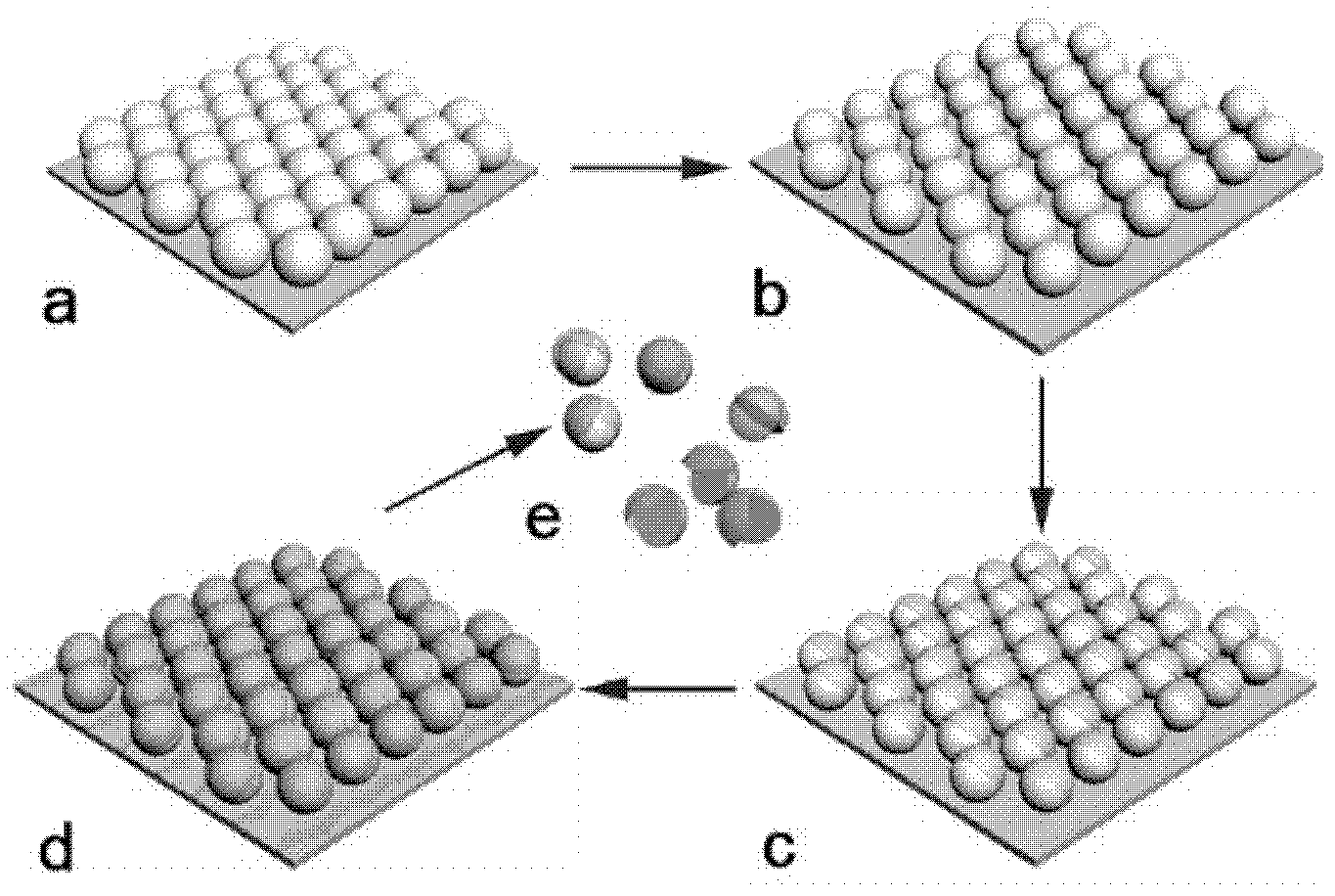

An asymmetric and microsphere technology, applied in the field of material science, can solve the problems of simple structure of asymmetric particles, single functional components, difficult to meet needs, etc., and achieve flexible control of modified materials and shapes, simple and controllable operation. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the preparation of hydrophilic silicon chip

[0026] The silicon chip used is a single crystal silicon chip (100), and the silicon chip is cut to 2 cm long and 2 cm wide with a glass knife, and put into a mixed solution of concentrated sulfuric acid and hydrogen peroxide (volume ratio is 7: 3) and heated in a water bath to Keep at 80°C for 5 hours to obtain hydrophilic silicon wafers; then pour the mixed solution into a waste liquid bottle, wash the obtained silicon wafers with deionized water for 3 to 5 times, and store them in deionized water for later use.

Embodiment 2

[0027] Embodiment 2: the preparation of hydrophobic glass sheet

[0028] The glass sheet used was cut to 2.5cm long and 3.5cm wide with a glass knife, put into a mixed solution of concentrated sulfuric acid and hydrogen peroxide (volume ratio 7:3) and heated to 80°C in a water bath, and kept for 5 hours to obtain the water glass flakes; pour the mixed solution into a waste liquid bottle, wash the obtained glass flakes with deionized water for 3 to 5 times, and dry them with nitrogen; put the prepared hydrophilic glass flakes into a small weighing bottle In a desiccator, drop two drops of fluorinated reagent into the weighing bottle, put the desiccator in a 60°C oven and heat for 3 hours to obtain hydrophobic glass flakes, take out the glass flakes and set aside. The fluorinating reagent is (Trichloro(1H,1H,2H,2H-perfluoroocty)silane, 1H,1H,2H,2H-perfluorooctyltrichlorosilane).

Embodiment 3

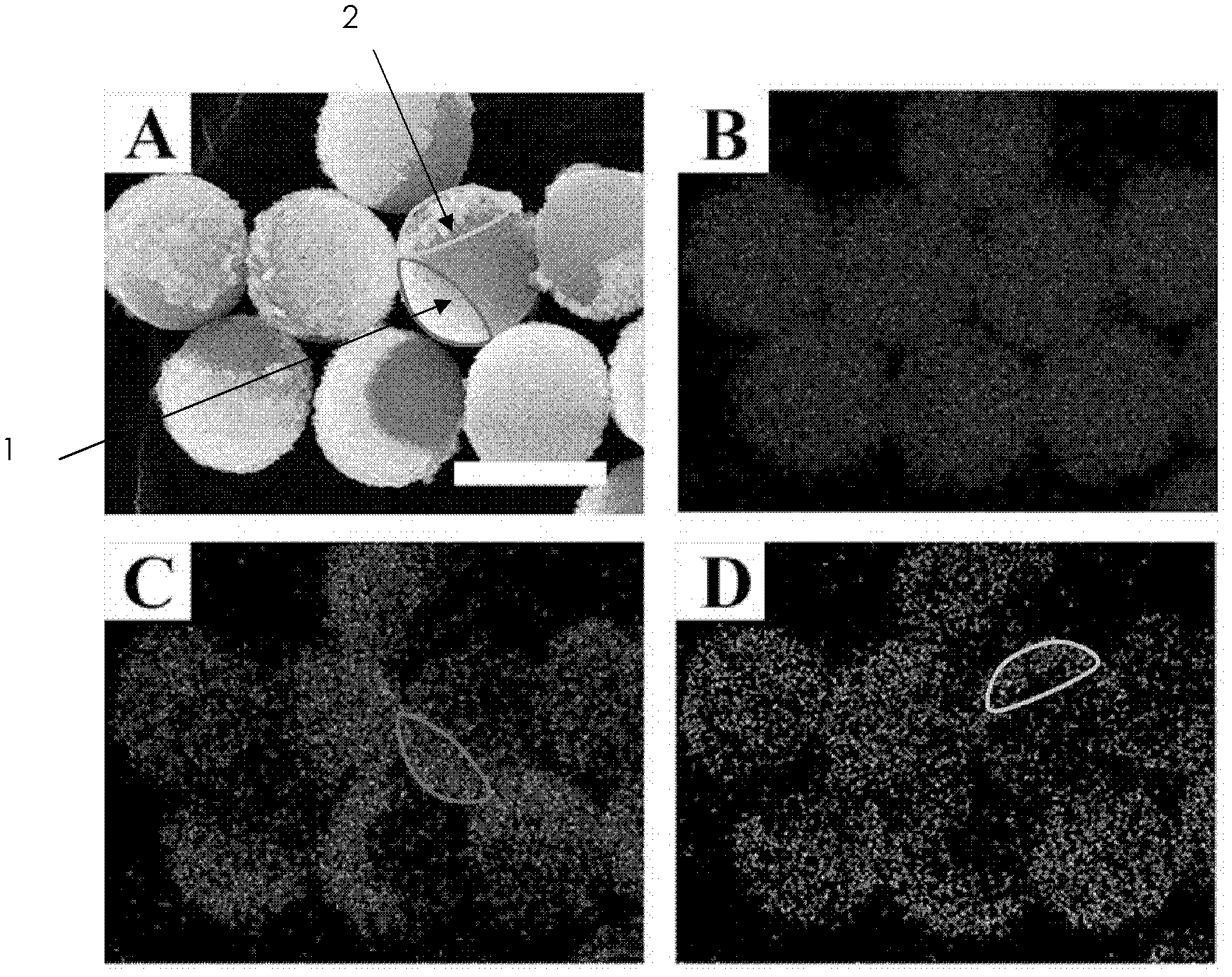

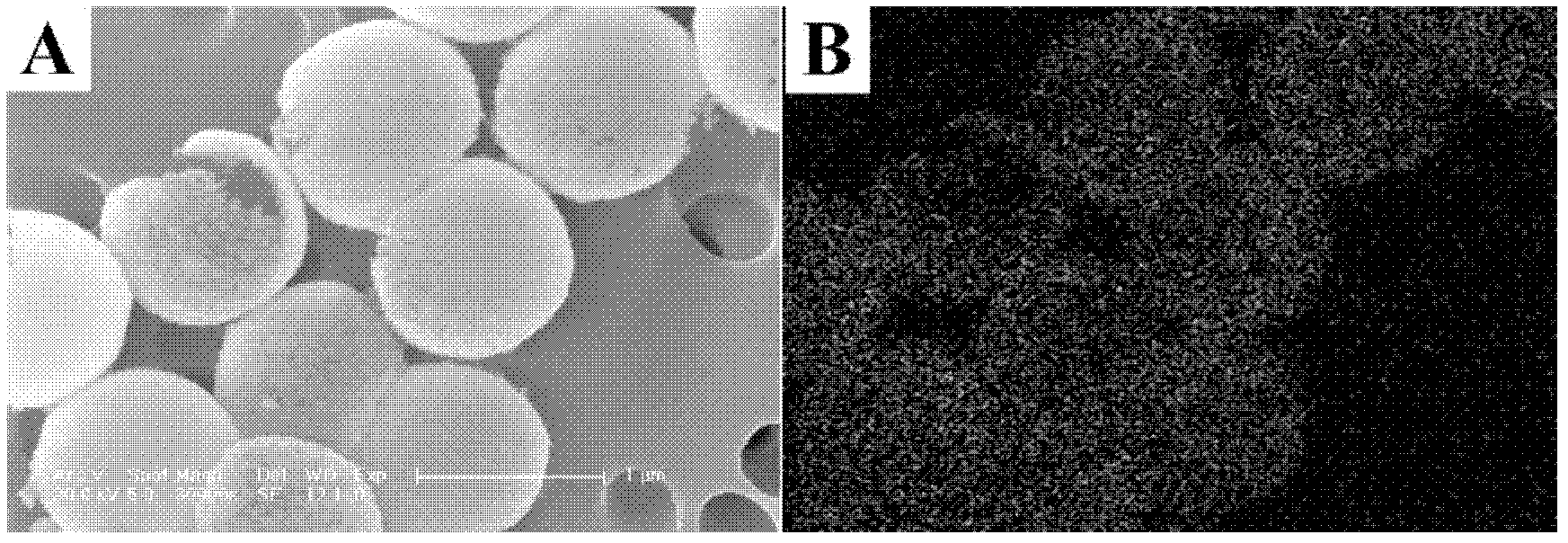

[0029] Embodiment 3: Preparation of hydrophobic silica microspheres

[0030] At normal temperature, get 10mL, 5wt%, the silica colloidal microsphere that diameter is 1 μ m (using Method prepared) ethanol dispersion liquid, at the same time, 10μL octadecyltrichlorosilane was dissolved in 0.5mL toluene, and then the two were mixed, after magnetic stirring for 8h, washed with ethanol centrifuge for 3 times, and the hydrophobic silica gel obtained at last The colloidal microspheres were dispersed in 10 mL of absolute ethanol to obtain an ethanol dispersion of 5 wt % hydrophobic silica colloidal microspheres, and the diameter of the microspheres was 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com