Microwave-synthesis method for preparation of copper-zinc-tin-sulphur (CZTS) nanoparticles

A nano-particle, copper-zinc-tin-sulfur technology, which is applied in the field of materials and preparations in the field of nano-photoelectric technology, can solve the problems of high energy consumption and long reaction time, and achieve the effects of reducing energy consumption, short preparation period and large output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

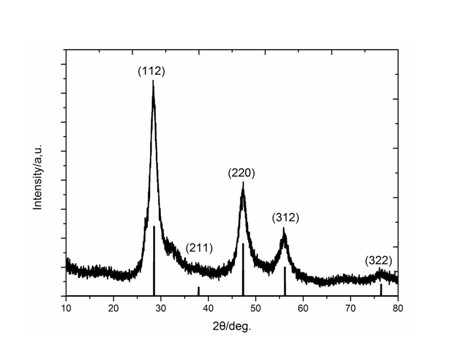

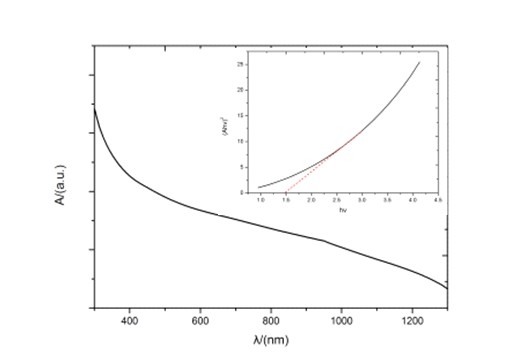

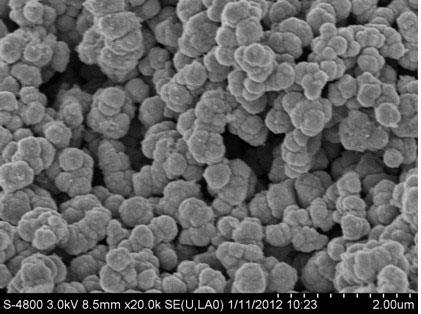

[0028] Weigh 1 mmol of zinc chloride, 1 mmol of tin dichloride, 2 mmol of copper chloride, and 4 mmol of sodium thiosulfate and dissolve them in 50 mL of ethylene glycol, stir them evenly and put them in a microwave oven for heating. to 800 W, react for 5 min, centrifuge and wash with ultrapure water to obtain Cu 2 ZnSnS 4 thin film nanoparticles. Prepared Cu 2 ZnSnS 4 The X-ray diffraction spectrum, absorption spectrum and scanning electron microscope pictures of nanoparticles are as follows: figure 1 , figure 2 and image 3 shown. Prepared Cu 2 ZnSnS 4 The nanoparticles have a (112) preferred orientation, their optical band gap is about 1.5 eV, the size of the nanoparticles is about 200-400 nm, and the element ratio in the nanoparticles is Cu:Zn:Sn:S=2.1:1:1.1:4.1 .

[0029]

Embodiment 2

[0031] Weigh 1 mmol of zinc chloride, 1 mmol of tin dichloride, 2 mmol of copper chloride, and 4 mmol of sodium thiosulfate and dissolve them in 50 mL of ethylene glycol, stir them evenly and put them in a microwave oven for heating. to 800 W, react for 20 min, centrifuge and wash with ultrapure water to obtain Cu 2 ZnSnS 4 thin film nanoparticles.

[0032]

Embodiment 3

[0034] Weigh 1 mmol of zinc chloride, 1 mmol of tin dichloride, 2 mmol of copper chloride, and 4 mmol of sodium thiosulfate and dissolve them in 50 mL of ethylene glycol, stir them evenly and put them in a microwave oven for heating. to 400 W, react for 20 min, centrifuge and wash with ultrapure water to obtain Cu 2 ZnSnS 4 thin film nanoparticles.

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com