Method for manufacturing amino-acid fishpond fertilizer water aqua by waste bave protein

An amino acid and protein technology, applied in chemical instruments and methods, applications, fish farming, etc., can solve problems such as high cost and limited sources, achieve low cost, good biodegradability, and reduce cost and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

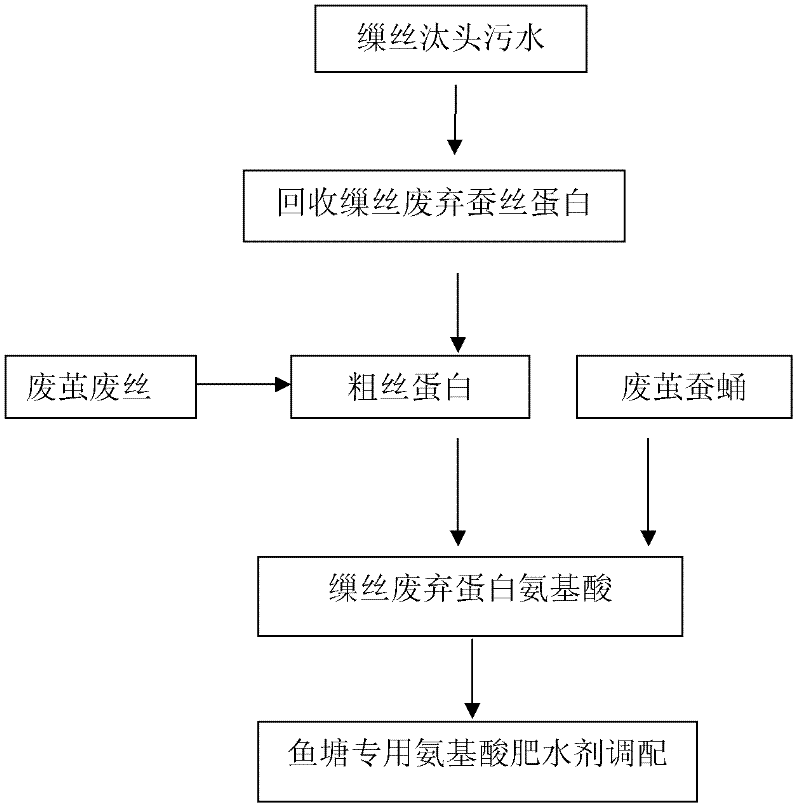

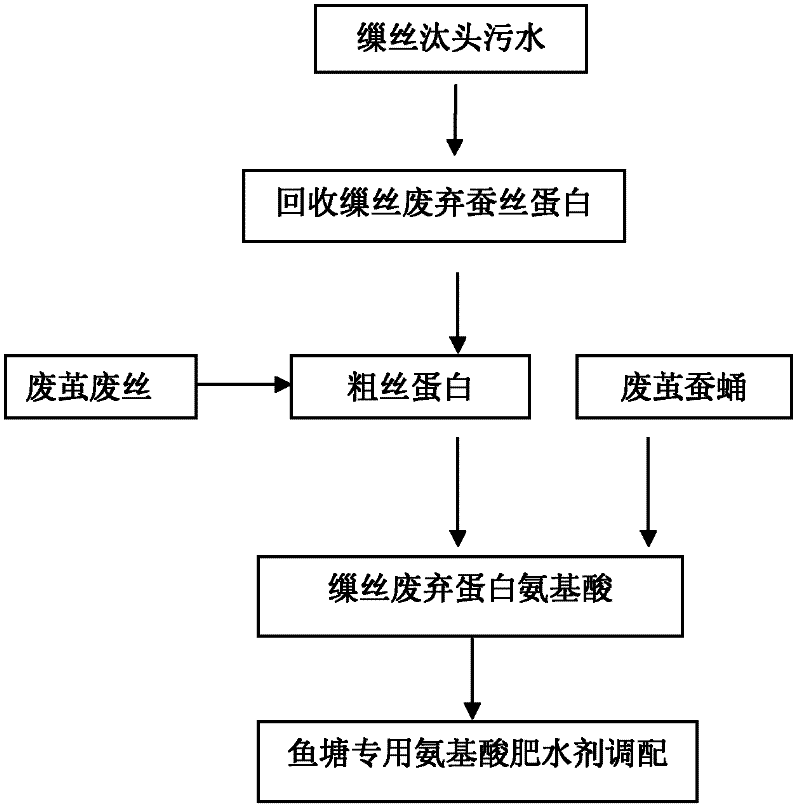

[0028] A method for using waste cocoon silk protein to manufacture amino acid fish pond fertilizer water preparation, comprising the following steps:

[0029] (1) Recovery of silk reeling waste silk protein: take the waste water from the reeling head, adjust the pH of the solution to the isoelectric point of sericin with hydrochloric acid, adjust the pH of the solution to 3.8-4.4 with hydrochloric acid, centrifuge for 30 minutes, remove the solution, and take The crude silk protein is obtained after the precipitation is concentrated in vacuo, soaked in a petroleum ether solution for 24 hours and degreasing, filtered, and the filtrate is taken and freeze-dried to obtain further purified crude silk protein.

[0030](2) Using waste cocoon and waste silk protein to prepare amino acids: take the crude silk protein obtained in step (1) and mix it with waste cocoon waste silk to obtain a mixture, hydrolyze the mixture with a 7% NaOH solution by mass, and add the mixture and NaOH solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com