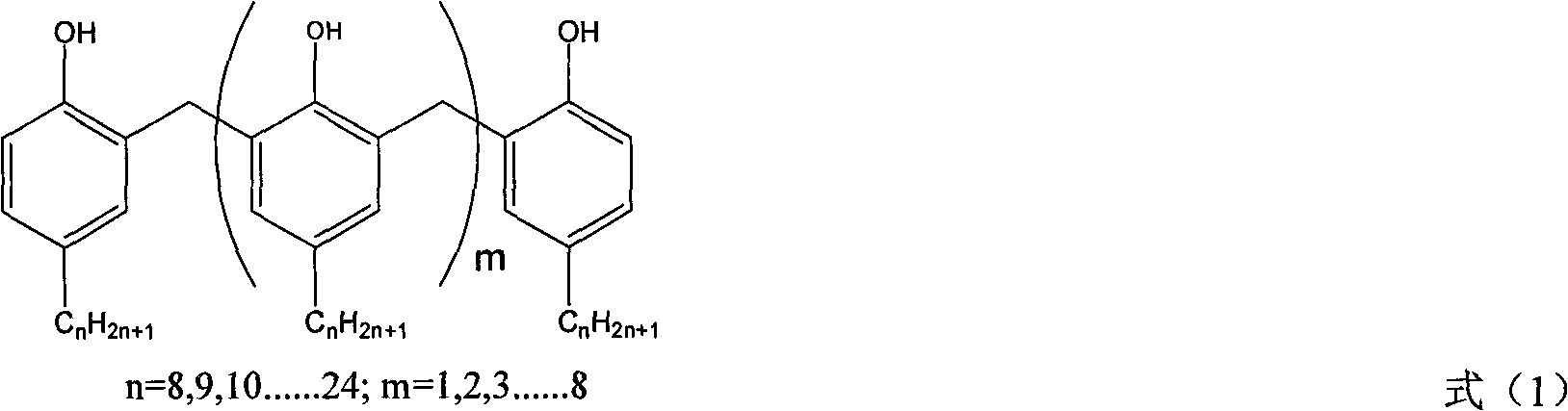

Process for preparing alkylphenol formaldehyde oligomer sulfonate

A technology for producing sulfonate and alkylsulfonic acid, which is applied in the preparation of sulfonic acid and organic chemistry, can solve the problems of long reaction time, time-consuming and energy-consuming, loss of cross-linking reaction, etc., and achieve simplified post-processing methods and shortened Operation cycle, the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: add C in the reactor with thermometer, stirrer, condenser tube 8 Linear alkylphenol, catalyst linear dodecylbenzene sulfonic acid, the amount of catalyst is 0.1% of the mass of alkylphenol, start stirring and after heating to 30°C, add dropwise 50% of the total injection mass of formaldehyde, and continue stirring After heating up to the reaction temperature of 60°C, the remaining formaldehyde was added, the molar ratio of alkylphenol to formaldehyde was 1:0.5, and the reaction was continued for 240 minutes at the reaction temperature. After the reaction, the pH of the reaction product was adjusted to 7.5 by adding an aqueous solution of sodium hydroxide, and finally a yellowish-brown colloidal substance, ie, an alkylphenol formaldehyde oligomer, was obtained.

[0037] Add alkylphenol formaldehyde oligomers into the reaction kettle with thermometer, agitator, and condenser, add isooctane to dissolve, start stirring and add appropriate amount of oleum when ...

Embodiment 2

[0038] Embodiment 2: add C in the reactor with thermometer, stirrer, condenser tube 9Branched-chain alkylphenol, catalyst p-toluenesulfonic acid, the amount of catalyst is 10.0% of the mass of alkylphenol, after starting stirring and heating to 50°C, add dropwise 60% of the total injection mass of paraformaldehyde, continue to stir and heat up to the reaction After the temperature was 120°C, the remaining paraformaldehyde was added, and the molar ratio of the alkylphenol to the formaldehyde in the paraformaldehyde was 1:5, and the reaction was continued for 30 minutes at the reaction temperature. After the reaction, the pH of the reaction product was adjusted to 6.5 by adding an aqueous solution of sodium hydroxide, and finally a yellow-brown colloidal substance was obtained, ie, an alkylphenol formaldehyde oligomer.

[0039] Add alkylphenol formaldehyde oligomers into a reaction kettle with a thermometer, agitator, and condenser, add cyclohexane to dissolve, start stirring an...

Embodiment 3

[0040] Embodiment 3: add C in the reactor with thermometer, stirrer, condensation pipe 12 Branched chain alkylphenol, catalyst isobutyl naphthalene sulfonic acid, the amount of catalyst is 5.0% of the mass of alkylphenol, start stirring and after heating to 40°C, add dropwise 80% of the total injection mass of formaldehyde, continue to stir and heat up to the reaction The remaining formaldehyde was added after the temperature was 80°C, the molar ratio of alkylphenol to formaldehyde was 1:1.5, and the reaction was continued for 90 minutes at the reaction temperature. After the reaction was completed, the pH of the reaction product was adjusted to 7.3 by adding an aqueous sodium hydroxide solution, and finally a yellow-brown colloidal substance, ie, an alkylphenol formaldehyde oligomer, was obtained.

[0041] Add alkylphenol formaldehyde oligomers into the reaction kettle with thermometer, stirrer, and condenser, add dichloromethane to dissolve, start stirring and heat to 50°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com