Environment-friendly EPDM (Ethylene Propylene Diene Monomer) and NBR (Nitrile Butadiene Rubber) combined closed-pore secondary foam material and preparation method thereof

A technology of EPDM rubber and nitrile rubber, which is applied in the field of environmentally friendly EPDM rubber and nitrile rubber combined with closed-cell secondary foaming materials and its preparation, to overcome the high halogen content, reduce costs, Effect of improving ozone resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

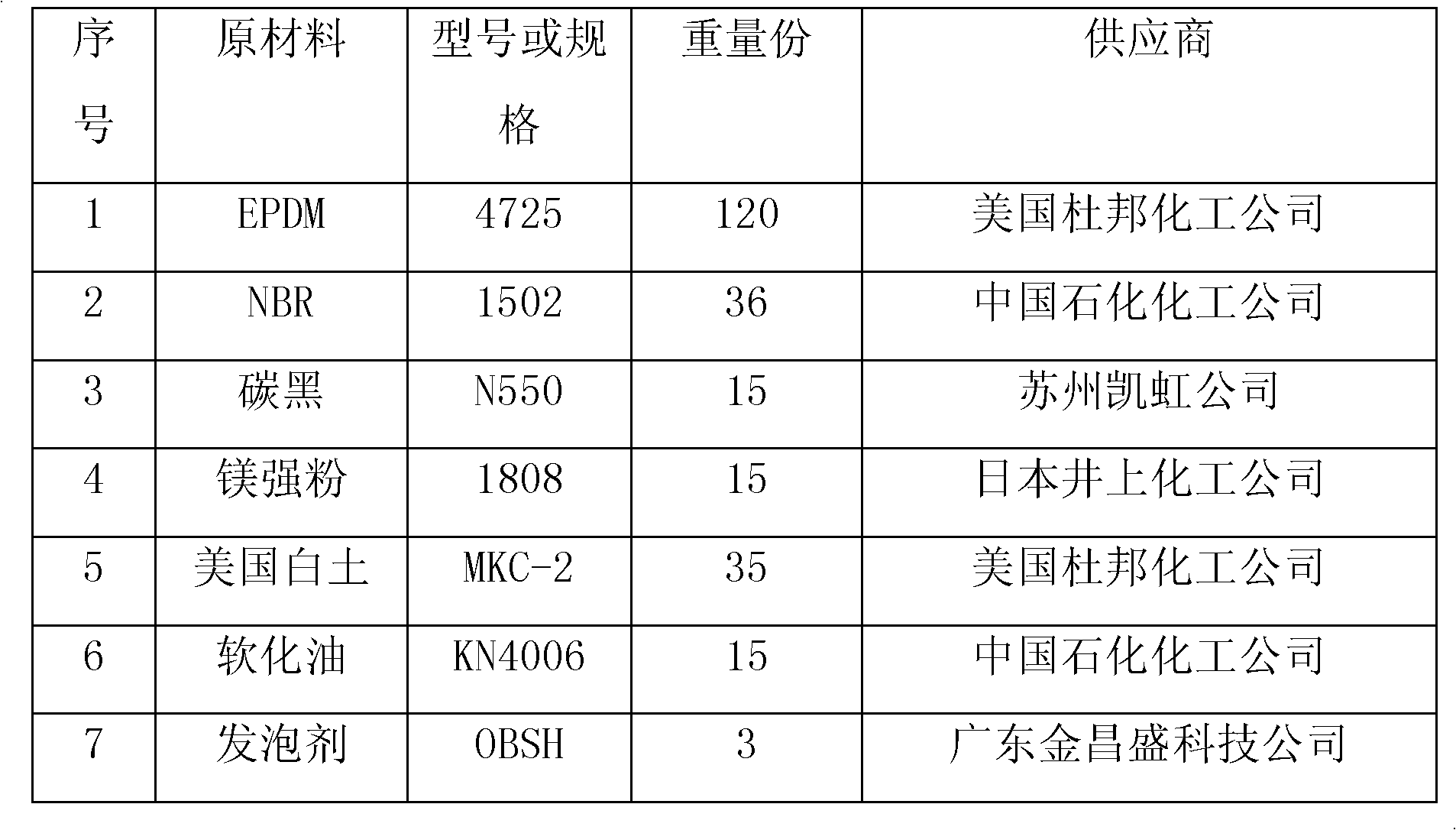

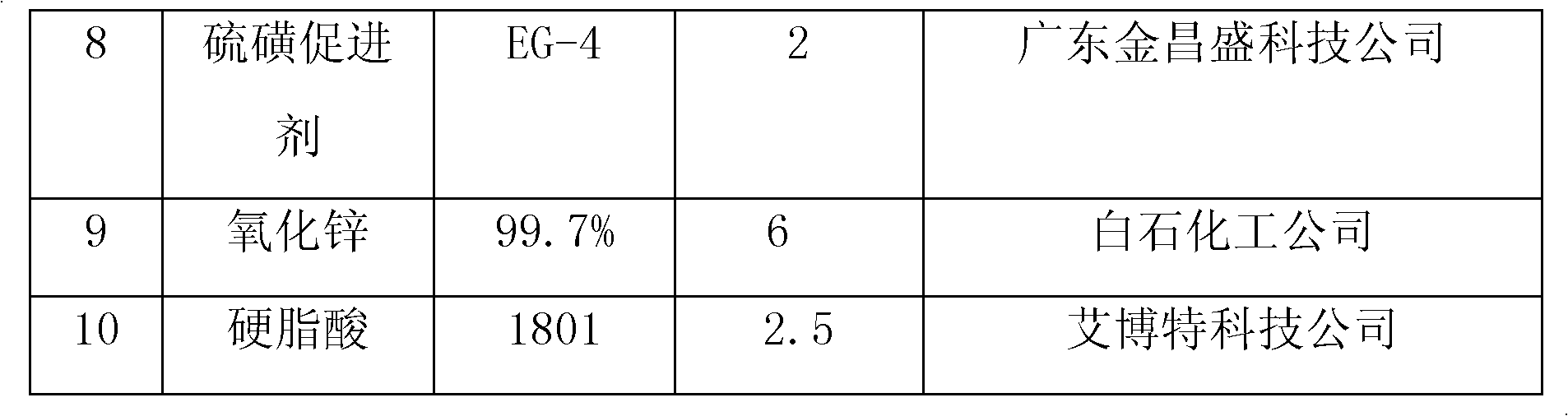

[0030] The formula of this embodiment is as shown in Table 1, EPDM is ethylene propylene diene monomer rubber, and NBR is nitrile butadiene rubber. The preparation method of present embodiment raw material is as follows:

[0031] (1) Banbury

[0032] A. Put EPDM, NBR, 1 / 2 ratio of carbon black, 1 / 2 ratio of magnesium powder, softening oil KN4006, and American white clay into the internal mixer according to the weight parts shown in Table 1 to form a mixed rubber.

[0033] B. Put zinc oxide and stearic acid 1801 in the parts by weight shown in Table 1 into the internal mixer and knead with the mixed rubber for 1-2min.

[0034] C. Put the remaining 1 / 2 ratio of carbon black and 1 / 2 ratio of magnesium powder into the internal mixer and knead for 1-2min.

[0035] D. Put the foaming agent OBSH and the sulfur accelerator EG-4 into the internal mixer according to the weight parts shown in Table 1, and then carry out pressurized kneading for 8-10min, and the hammer pressure is 5KG. ...

Embodiment 2

[0049] The formula of this embodiment is as shown in Table 4, EPDM is ethylene propylene diene monomer rubber, and NBR is nitrile butadiene rubber. The preparation method of the foam material of this embodiment is the same as that of Embodiment 1.

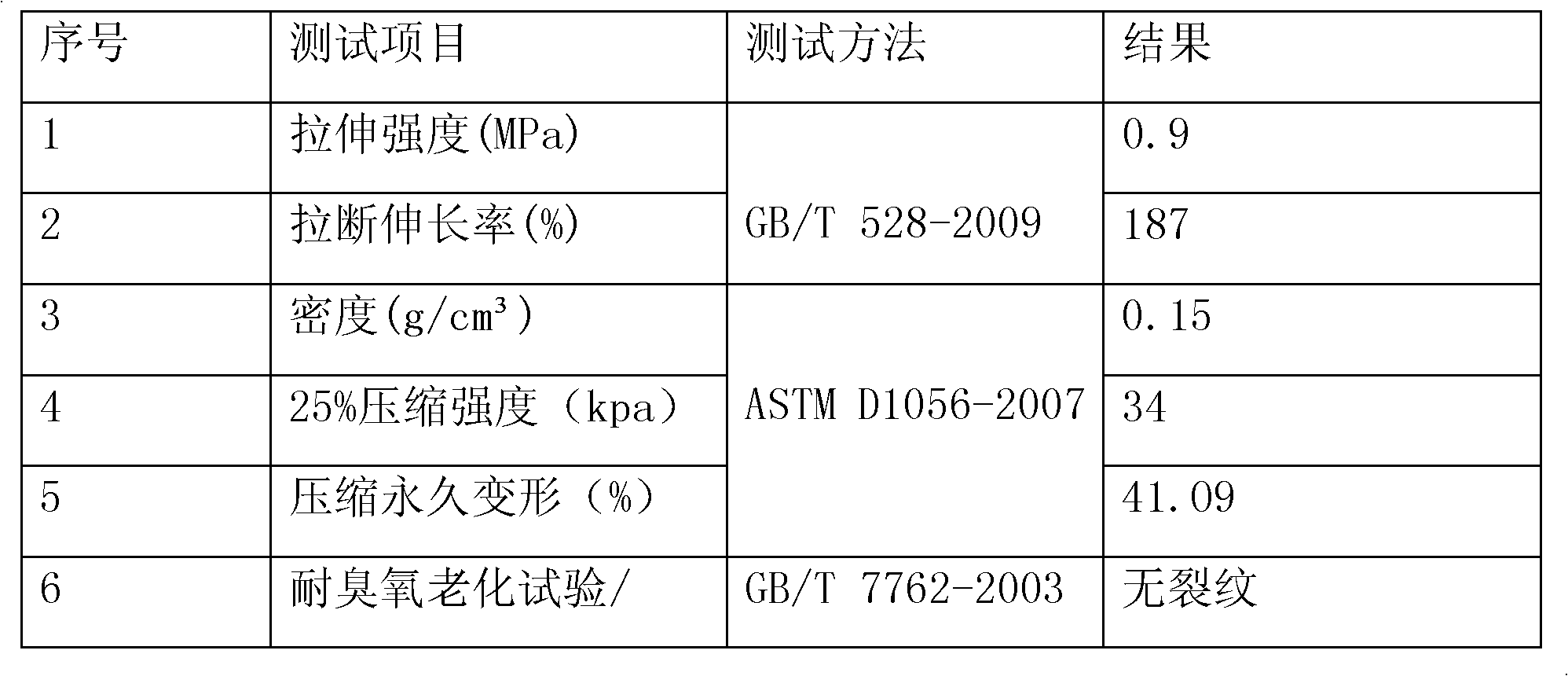

[0050] Table 2 also shows the physical performance test results of the halogen-free environment-friendly EPDM rubber and nitrile rubber combined with secondary closed-cell foaming materials obtained in the present invention. In this example, the halogen-free and environment-friendly EPDM and NBR combined with the secondary closed-cell foaming material SGS halogen element test report is also shown in Table 3.

[0051]The combination of EPDM and NBR rubber in this example has excellent ozone resistance, aging resistance and good oil resistance, solvent resistance and chemical resistance through a reasonable formula and preparation process. It can be seen from the previous two test reports , the halogen-free environment-friendly EPDM...

Embodiment 3

[0053] The formula of this embodiment is as shown in Table 5, EPDM is ethylene-propylene-diene rubber, and NBR is nitrile butadiene rubber. The preparation method of the foam material of this embodiment is the same as that of Embodiment 1.

[0054] Table 2 also shows the physical performance test results of the halogen-free environment-friendly EPDM rubber and nitrile rubber combined with secondary closed-cell foaming materials obtained in the present invention. In this example, the halogen-free and environment-friendly EPDM and NBR combined with the secondary closed-cell foaming material SGS halogen element test report is also shown in Table 3.

[0055] The combination of EPDM and NBR rubber in this example has excellent ozone resistance, aging resistance and good oil resistance, solvent resistance and chemical resistance through a reasonable formula and preparation process. It can be seen from the previous two test reports , the halogen-free environment-friendly EPDM and NB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com