Method for refining enhanced oil product solvent

A solvent refining and solvent technology, applied in the direction of refining with two or more solvents, refining hydrocarbon oil, petroleum industry, etc., can solve the problems of small improvement and no obvious effect of reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

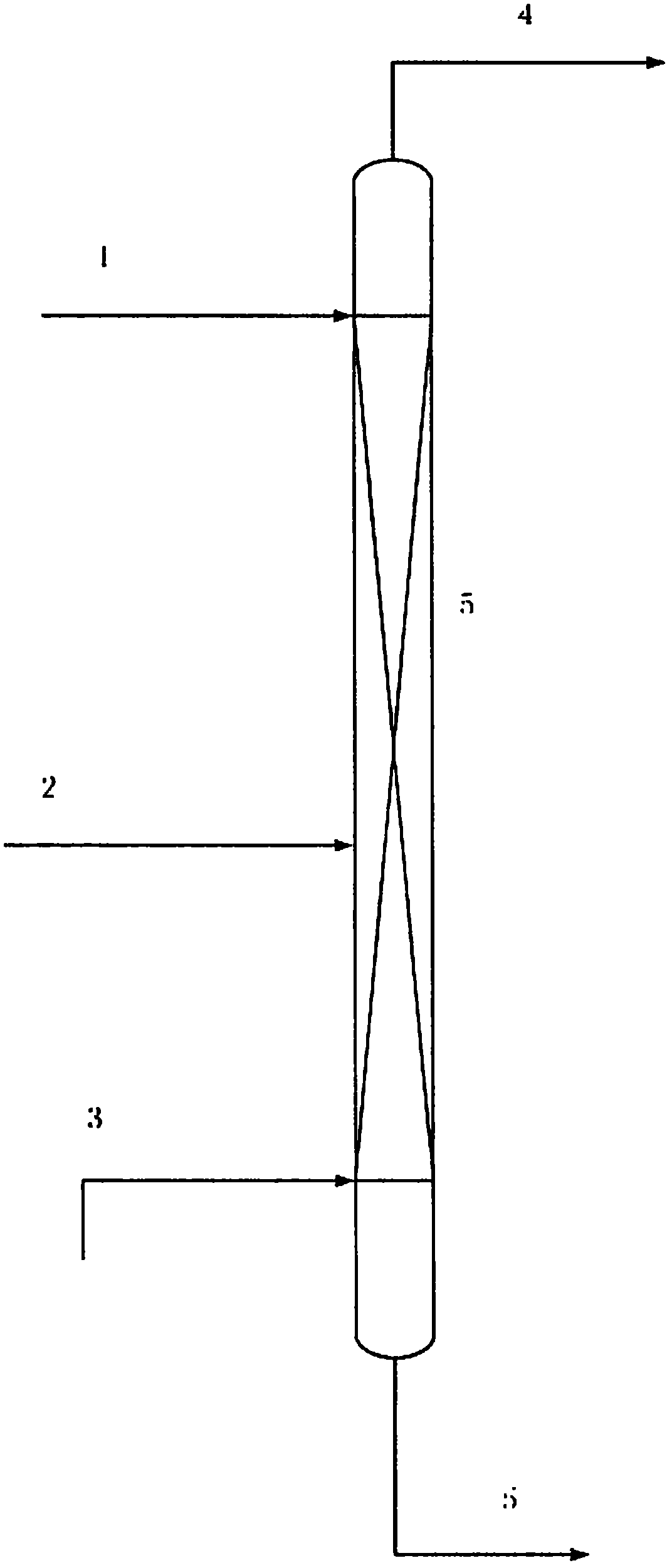

Embodiment 1

[0011] The second-line distillate produced by a refinery is refined with furfural as a solvent. The refining process is carried out in a packed extraction tower with a height of 3000mm and an inner diameter of 30mm. The top of the tower is the outlet of the refined liquid, and the bottom of the tower is the discharge of the extracted liquid 300mm from the top of the tower is the inlet of furfural, 400mm from the bottom of the tower is the inlet of enhanced extractant, and 1000mm from the bottom of the tower is the inlet of raw material oil. The interface with the oil, the refined liquid and the extracted liquid are evaporated to recover the solvent to obtain the refined oil and the extracted oil. Control tower top temperature 100 ℃, tower bottom temperature 70 ℃, the agent oil mass ratio of furfural and raw oil is 2: 1, the yield of refined oil is 65%, viscosity index is 86, and saturated hydrocarbon content in the extracted oil is 32%; The enhanced extraction process provided...

Embodiment 2

[0013] The content of saturated hydrocarbons in the catalytic cracking oil slurry produced by a refinery is 31%. Using the refining equipment in Example 1, the temperature at the top of the tower is 70°C, the temperature at the bottom of the tower is 50°C, and the mass ratio of agent to oil is 1:1. After being refined with a solvent, the yield of its refined oil is 20%, of which the saturated hydrocarbon content is 81.0%, and the saturated hydrocarbon content in the extracted oil is 15.1%; the enhanced extraction process is adopted, and the mixed alkanes of C7-C12 are used as the enhanced solvent. The amount accounts for 20% of the raw oil, and other conditions remain unchanged, the yield of refined oil reaches 35%, of which the saturated hydrocarbon content is 81.5%, and the saturated hydrocarbon content in the extracted oil is reduced to 5.5%. The yield of refined oil reaches 38%, wherein the saturated hydrocarbon content is 80.7%, and the saturated hydrocarbon content in the...

Embodiment 3

[0015] The content of saturated hydrocarbons in the catalytic cracking oil slurry produced by a refinery is 31%. Using the refining equipment in Example 1, the temperature at the top of the tower is 70°C, the temperature at the bottom of the tower is 50°C, and the mass ratio of agent to oil is 1:1. After being refined by solvent, the yield of its refined oil is 21%, wherein the content of saturated hydrocarbon is 80.2%, and the content of saturated hydrocarbon in the extracted oil is 17.2%; the enhanced extraction process is adopted, and the mixed alkanes of C7-C12 are used as the enhanced solvent, and the The amount accounts for 20% of the raw oil, and other conditions remain unchanged. The yield of refined oil reaches 36.1%, of which the saturated hydrocarbon content is 81.3%, and the saturated hydrocarbon content in the extracted oil is reduced to 5.2%. The yield of refined oil reaches 38%, wherein the saturated hydrocarbon content is 80.1%, and the saturated hydrocarbon con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap