Modification method of aramid fiber in supercritical CO2 by surface grafting polymerization

A kind of aramid fiber and surface grafting technology, applied in the field of modification of aramid fiber, can solve the problems of poor reaction, low inoculation rate, complicated operation, etc. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Cleaning of aramid fiber surface:

[0031] Put the acetone solution in the three-necked flask, and put the aramid fiber in the Soxhlet extractor. Heat the acetone to 70°C, wash the surface of the aramid fiber after the acetone is condensed and refluxed, and take out the vacuum-dried fiber after 24 hours of cleaning time.

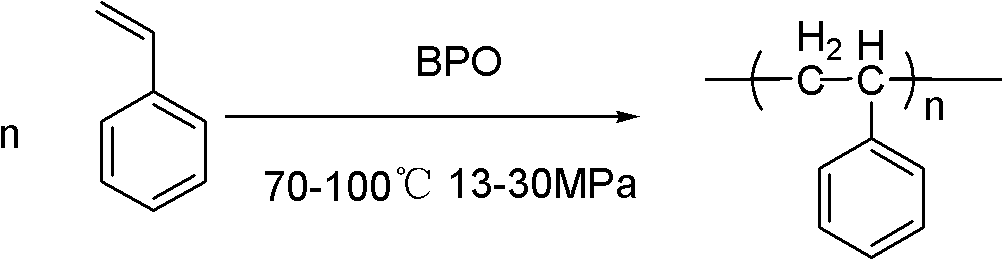

[0032] (2) Aramid fiber surface graft polymerized styrene

[0033] A certain amount (BPO / St=0.3-1wt%) of initiator (take BPO as an example) and monomer St are added to the bottom of the autoclave, and aramid fibers whose surface has been cleaned (without contact with monomer and initiator) are added. Close the autoclave and fill the autoclave with CO 2 and discharge CO 2 three times to expel the air. Fill the kettle with CO 2 , and heat the system so that the pressure reaches 13-30MPa, the temperature is 45-50°C, and the system is in supercritical CO 2 state. After swelling the aramid fiber for 4-8 hours, directly heat the system to 70-100°...

Embodiment 2

[0039] (1) Cleaning of aramid fiber surface:

[0040] Put the acetone solution in the three-necked flask, and put the aramid fiber in the Soxhlet extractor. Heat the acetone to 70°C, wash the surface of the aramid fiber after the acetone is condensed and refluxed, and take out the vacuum-dried fiber after 24 hours of cleaning time.

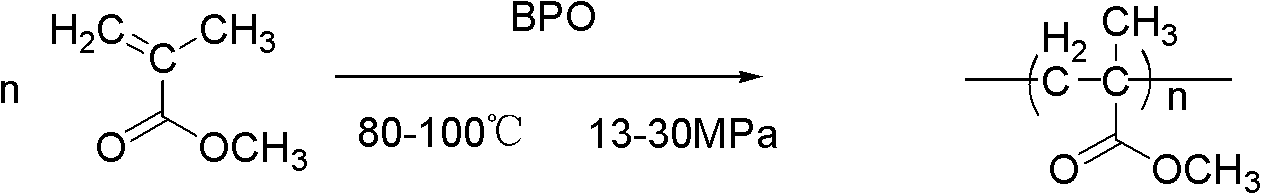

[0041] (2) Aramid fiber surface graft polymerization methyl methacrylate

[0042] A certain amount (BPO / MMA=0.4-3wt%) of initiator and monomer MMA are added to the bottom of the autoclave, and aramid fiber (without contact with monomer and initiator) whose surface has been cleaned is added. Close the autoclave and fill the autoclave with CO 2 and discharge CO 2 three times to expel the air. Fill the kettle with CO 2 , and heat the system so that the pressure reaches 8-30MPa, the temperature is 45-50°C, and the system is in supercritical CO 2 state. After swelling the aramid fiber for 4-8 hours, directly heat the system to 80-100°C to initia...

Embodiment 3

[0048] (1) Cleaning of aramid fiber surface:

[0049] Put the acetone solution in the three-necked flask, and put the aramid fiber in the Soxhlet extractor. Heat the acetone to 70°C, wash the surface of the aramid fiber after the acetone is condensed and refluxed, and take out the vacuum-dried fiber after 24 hours of cleaning time.

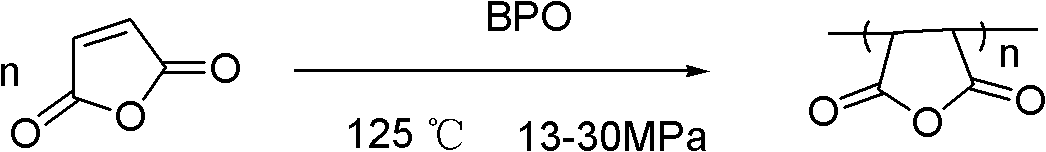

[0050] (2) Graft polymerization of maleic anhydride on the surface of aramid fibers

[0051] A certain amount (BPO / MAH=0.4-3wt%) initiator and monomer MAH are added to the bottom of the autoclave, and aramid fibers whose surface has been cleaned (without contact with monomer and initiator) are added. Close the autoclave and fill the autoclave with CO 2 and discharge CO 2 three times to expel the air. Fill the kettle with CO 2 , and heat the system so that the pressure reaches 13-30MPa, the temperature is 45-50°C, and the system is in supercritical CO 2 state. After swelling the aramid fiber for 4-8 hours, directly heat the system to 125°C t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com