Ablative black film for directly making plate by flexographic plate computer and preparation method of ablative black film

A technology of ablating black film and computer, which is applied in the photoengraving process of pattern surface, originals for photomechanical processing, photosensitive materials for photomechanical equipment, etc. It can solve the problem of many steps and poor image and text restoration. , poor film formation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

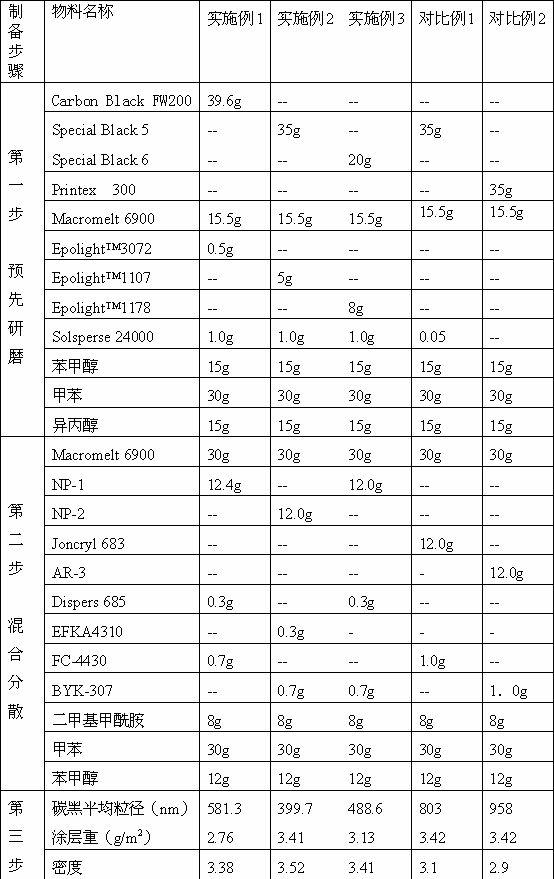

Embodiment 1

[0062] Take by weighing 39.6 grams of Carbon Black FW2000 in Example 1 in Table 1, 15.5 grams of Macromelt 6900 polyamide, 0.5 grams of Epolight 3072 infrared laser dye and 1.0 grams of Solsperse 24000 hyperdispersant, add to 15 grams of benzyl alcohol, 30 grams of toluene , isopropanol 15 grams of mixed solvent, first use the SWFS-400 laboratory high-speed disperser of Shanghai Sower Company to disperse for 1 hour, and then use the SMA laboratory basket mill of Shanghai Sower Company to grind for 3-5 hours When the test carbon black particle size reaches 50-800nm, complete the first step of pre-grinding the slurry and keep it for later use.

[0063] Subsequently, 30 grams of Macromelt 6900 polyamide, 12.6 grams of polyether polyurethane compound modified by NP-1 monoisocyanate, 0.3 grams of Dispers 685 super dispersant, and 0.7 grams of FC-4430 surfactant were added to dimethyl In a mixed solvent composed of 8 grams of formamide, 30 grams of toluene, and 12 grams of benzyl al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com