Preparation method for manganese dioxide three-dimensional graphene composite material with controllable appearance

A technology of manganese dioxide and composite materials, which is applied in the direction of electrical components, electrolytic capacitors, capacitors, etc., can solve the problems of poor electrical conductivity, low specific surface area, and difficult to control the shape of manganese dioxide, and achieves low price and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The three-dimensional graphene sheet synthesized by chemical vapor deposition was fixed on the glass sheet with 0.2mL of organic silica gel with a concentration of 48g / L;

[0026] Add 0.32g of potassium permanganate and 30ml of distilled water into a 0.05L reactor, stir with a glass rod for 3 minutes, put the three-dimensional graphene sheet fixed on the glass into the solution, and react at 150°C for 6 hours.

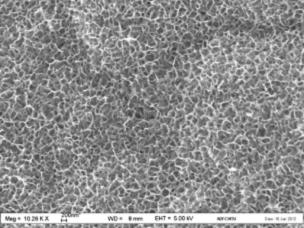

[0027] Rinse the reacted three-dimensional graphene with distilled water for 3 times, and then dry it in an oven at 80° C. for 4 hours to form a manganese dioxide three-dimensional graphene composite ( figure 1 ).

Embodiment 2

[0029] The three-dimensional graphene sheet synthesized by chemical vapor deposition was fixed on the glass sheet with 0.2mL of organic silica gel with a concentration of 48g / L;

[0030] Add 0.32g of potassium permanganate, 29ml of distilled water and 1ml of 1M hydrochloric acid aqueous solution into a 0.05L reaction kettle. After stirring with a glass rod for 5 minutes, put the three-dimensional graphene sheet fixed on the glass piece into the solution and heat it at 150°C. React for 6 hours.

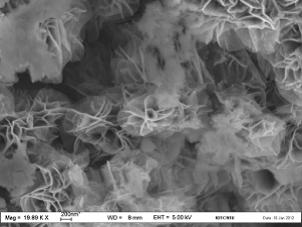

[0031] Rinse the reacted three-dimensional graphene with distilled water for 3 times, and dry it in an oven at 80° C. for 4 hours to form a manganese dioxide three-dimensional graphene composite with an irregular flower-like surface ( figure 2 ).

Embodiment 3

[0033] The three-dimensional graphene sheet synthesized by chemical vapor deposition was fixed on the glass sheet with 0.2mL of organic silica gel with a concentration of 48g / L;

[0034] Add 0.32g of potassium permanganate, 27ml of distilled water and 3ml of 1M hydrochloric acid aqueous solution into a 0.05L reaction kettle. After stirring with a glass rod for 5 minutes, put the three-dimensional graphene sheet fixed on the glass piece into the solution and heat it at 150°C. React for 6 hours.

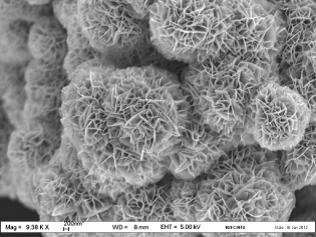

[0035] Rinse the reacted three-dimensional graphene with distilled water for 3 times, and dry it in an oven at 80° C. for 4 hours to form a rosette-shaped manganese dioxide three-dimensional graphene composite ( image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com