Method for preparing carbon counter electrode in dye sensitized solar cell

A solar cell and dye sensitization technology, which is applied in the field of optoelectronic materials and devices, can solve the problem of low catalytic activity, achieve the effects of improving catalytic activity, reducing preparation time, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

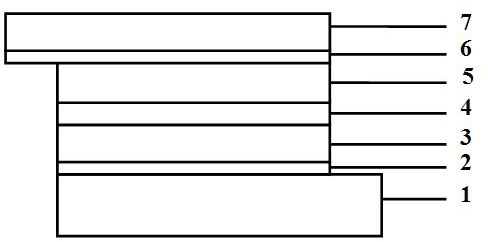

Image

Examples

Embodiment 1

[0047] 1) Wash. Based on high-purity Ti sheet and FTO glass. For the Ti sheet, first use sandpaper to polish the surface to remove obvious impurities and polish it smoothly, then dip a cotton swab into the deionized water solution containing detergent, scrub the substrate, then rinse it with deionized water solution containing detergent, and then use Ultrasonic cleaning with deionized water, ethanol, deionized water, and acetone for 10 minutes, followed by immersion in dilute hydrochloric acid for 30 minutes to remove metal impurities, then ultrasonic cleaning with acetone for 10 minutes, and drying for later use. For FTO glass, first use a cotton swab to dip in a deionized water solution containing detergent, scrub the substrate, then rinse it with a deionized water solution containing detergent, and then use deionized water, ethanol, deionized water, and acetone to ultrasonically Wash for 10 minutes and dry for later use.

[0048] 2) Prepare the photoanode. Spin coating o...

Embodiment 2

[0055] 1) Wash. Based on carbon cloth and FTO glass. Soak the carbon cloth with acetone for about 8 hours to remove the glue. For the FTO glass, dip a cotton swab into the deionized water solution containing detergent, scrub it, and then rinse it with the deionized water solution containing detergent, and then sequentially Ultrasonic cleaning with deionized water, ethanol, deionized water, and acetone for 20 minutes, and drying for later use.

[0056] 2) Prepare the photoanode. Spin-coat 100 nm of TiO on clean FTO glass 2 dense layer, followed by sintering at 550 °C for 10 min, and then in dense TiO 2 A layer of TiO commonly used in DSSC is coated on the 2 emulsion, followed by sintering at 500 °C for 20 min to form TiO 2 Porous layer, repeated above coating and sintering process can control TiO 2 The thickness of the porous layer is about 12 μm. The sintered photoanode is immersed in a 0.3 mmol / L N719 dye ethanol solution at 60 ° C for more than 15 hours, and then taken...

Embodiment 3

[0062] 1) Wash. Based on stainless steel sheet and FTO glass. For stainless steel sheets, first use sandpaper to polish the surface to remove obvious impurities and polish it smoothly, then use a cotton swab to dip in deionized water solution containing detergent, scrub the substrate, then rinse with deionized water solution containing detergent, and then use Ultrasonic cleaning with deionized water, ethanol, deionized water, and acetone for 10 minutes, and drying for later use. For FTO glass, first use a cotton swab to dip in a deionized water solution containing detergent, scrub the substrate, then rinse it with a deionized water solution containing detergent, and then use deionized water, ethanol, deionized water, and acetone to ultrasonically Wash for 10 minutes and dry for later use.

[0063] 2) Prepare the photoanode. Spin-coat 100 nm of TiO on clean FTO glass 2 dense layer, followed by sintering at 550 °C for 10 min, and then in dense TiO 2 A layer of TiO commonly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com