Aluminum clad manganese-base laminated composite lithium ion battery cathode material and preparation method thereof

A positive electrode material and ion battery technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of uncoated treatment, high initial charge voltage platform, and low charge and discharge efficiency, so as to improve the initial charge and discharge efficiency, The effect of the first charging voltage platform is low and the capacity is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

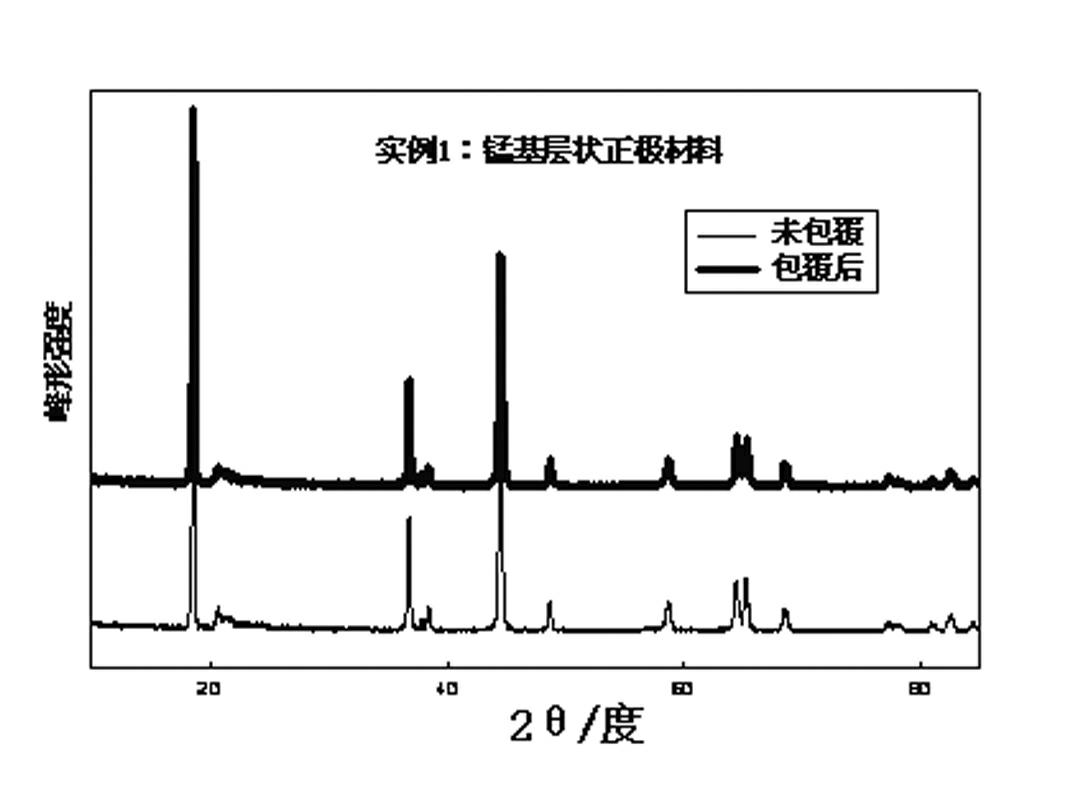

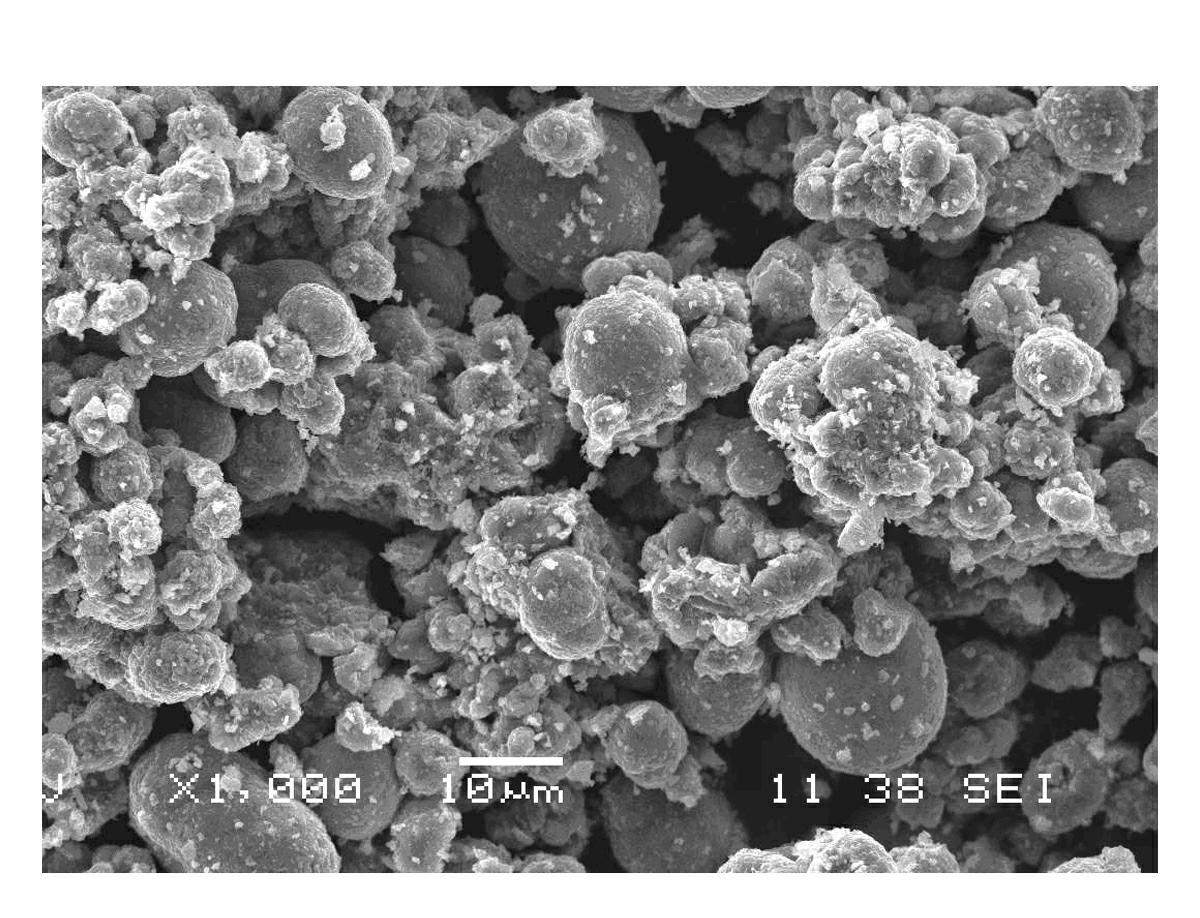

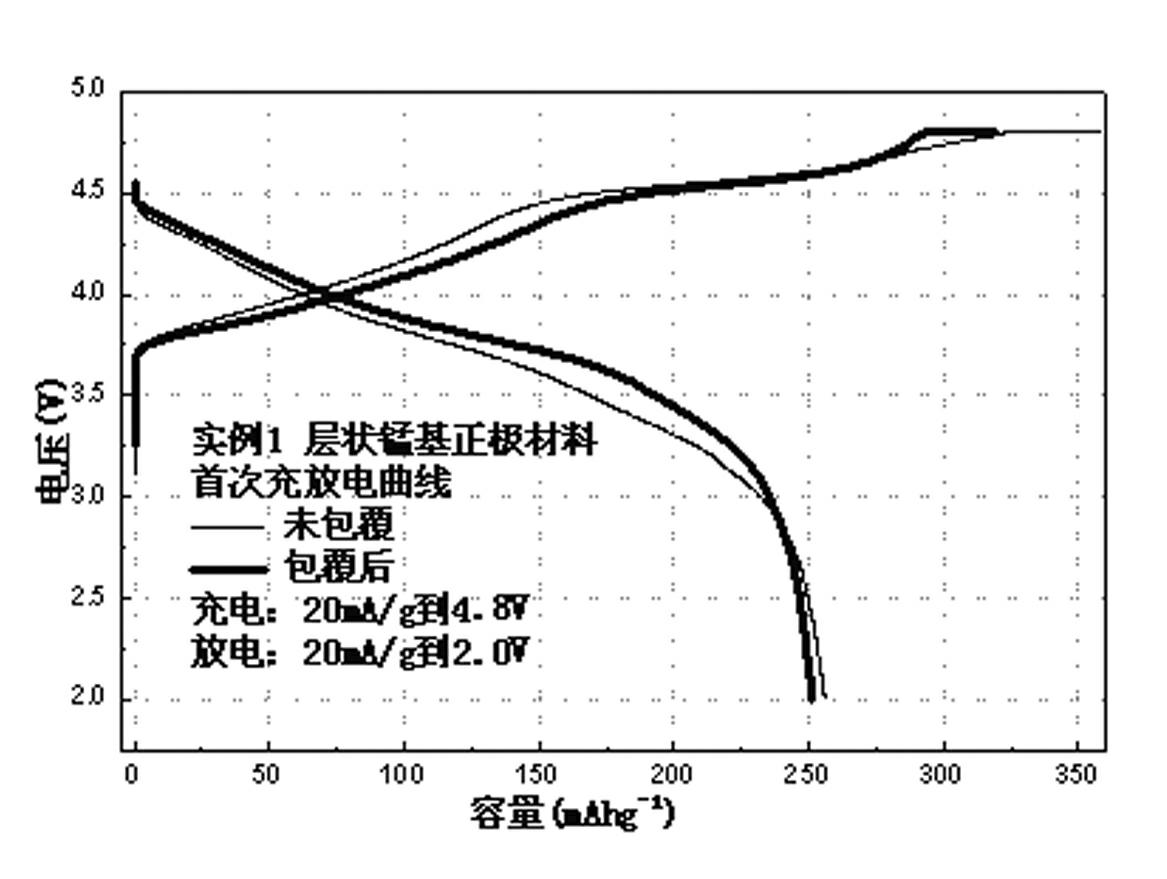

Embodiment 1

[0028] The anode material of the aluminum-coated manganese-based layered composite lithium-ion battery of the present embodiment is Li(Li 0.2 mn 0.65 Ni 0.33 al 0.02 )O 2 The layered structure of the manganese-based cathode material is coated with aluminum salt; the coating amount is Al / Li(Li 0.2 mn 0.65 Ni 0.33 al 0.02 )O 2 The mass ratio is 0.02%.

[0029] Its preparation method is:

[0030] (1) Prepare the mixture: according to the molecular formula, it is Li(Li 0.2 mn 0.65 Ni 0.33 al 0.02 )O 2 Ratio, the molar ratio is Mn:Ni=0.65:0.33 hydroxide precursor nickel manganese hydroxide 10.000Kg and 35.979kg purity is lithium carbonate (Li 2 CO 3 ), 3.119kg of micron grade Al with a purity of 99% 2 o 3 , added to the mixing tank, mixed evenly, and the elemental composition was Li(Li 0.2 mn 0.65 Ni 0.33 al 0.02 )O 2 mixture;

[0031] (2) Sintering and grinding: At 900°C, the elemental composition obtained in step (1) is Li(Li 0.2 mn 0.65 Ni 0.33 al 0.0...

Embodiment 2-4

[0045] The differences between Examples 2-4 and Example 1 are listed in Table 1, and other operations are the same as Example 1.

[0046]

[0047] Table 1 Uncoated and Al-coated manganese-based layered cathode materials synthesized under different conditions

[0048] Example components Substance used for coating Coated Al mass percentage (%) First discharge capacity (mAh / g) First charge and discharge efficiency (%) 30-week cycle retention rate (%) 2 Li(Li 0.2 mn 0.65 Fe 0.30 Al 0.05 )O 2 Aluminum nitrate, ammonia water 0.02 228.5 69.8 97.4 2 Comparative example Li(Li 0.2 mn 0.65 Fe 0.30 al 0.05 )O 2 - - 235.1 64.0 93.7 3 Li(Li 0.2 mn 0.60 co 0.38 Mg 0.02 )O 2 Aluminum nitrate, ammonium fluoride 0.05 246.7 81.6 98.6 3 Comparative example Li(Li 0.2 mn 0.60 co 0.38 Mg 0.02 )O 2 - - 250.6 73.2 94.5 4 Li(Li 0.2 mn 0.648 Ni 0.228 co 0.114 Ti 0.01 )O 2 Aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com