Preparation method of electrode of proton exchange membrane fuel cell and proton exchange membrane fuel cell

A technology for fuel cell electrodes and proton exchange membranes, applied to battery electrodes, circuits, electrical components, etc., can solve problems such as poor repeatability, complicated operation, and long production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention discloses a method for preparing a proton exchange membrane fuel cell electrode, which comprises the following steps:

[0039] a) Place the support layer on the surface of the bottom plate and fix it with negative pressure;

[0040] b), using ultrasonic spraying to spray the catalyst slurry on the surface of the support layer under the action of the carrier gas;

[0041] c), drying;

[0042] d) heat treatment to obtain proton exchange membrane fuel cell electrodes.

[0043] The reason why the present invention adopts the mode of ultrasonic spraying to prepare catalyst layer mainly lies in the following points:

[0044] First of all, ultrasonic spraying is to spray the catalyst slurry layer by layer on the surface of the support layer under the action of carrying current. Compared with the paste method and rolling method, the uniformity of the catalyst distribution on the surface of the support layer is improved, thereby improving the catalyst efficiency....

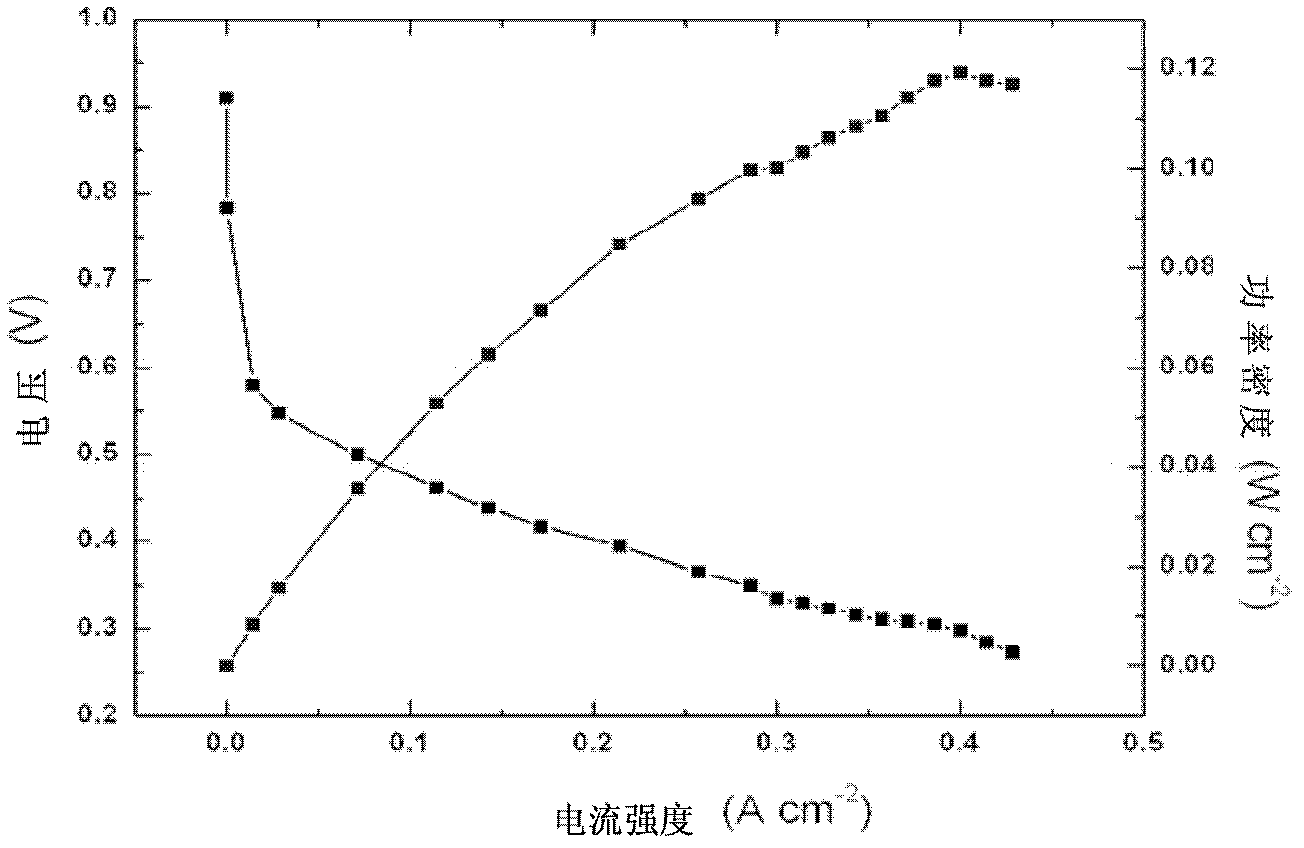

Embodiment 1

[0074] 1. Prepare anode catalyst slurry

[0075] 101. Weigh 0.4g of 40wt%Pt20wt%Ru / C catalyst, add 2ml of deionized water, and stir ultrasonically for 5 minutes;

[0076] 102. Add 12 ml of deionized water and ethanol mixed solvent with a volume ratio of 5:1, 0.3 g of polytetrafluoroethylene emulsion (solid content 50%), and 3 ml of Nafion solution with a concentration of 5 wt%, and stir ultrasonically for 30 minutes to obtain a catalyst anode slurry.

[0077] 2. Spraying

[0078] Take an area of 200cm 2 The carbon paper is placed on the porous bottom plate and fixed under negative pressure. The bottom plate is heated to 45°C, and then the above catalyst slurry is sprayed uniformly on the porous bottom plate by ultrasonic spraying, using nitrogen as the carrier gas, and the flow rate is 10ml / min;

[0079] 3. After spraying, place it at room temperature for 30 minutes to dry;

[0080] 4. Put the electrode obtained in step 3 into a muffle furnace under the protection of nit...

Embodiment 2

[0082] 1. Prepare anode catalyst slurry

[0083] 101. Weigh 0.4g of 40wt%Pt20wt%Ru / C catalyst, add 2ml of deionized water, and stir ultrasonically for 5 minutes;

[0084] 102. Add 12 ml of deionized water and ethanol mixed solvent with a volume ratio of 5:1, 0.08 g of polytetrafluoroethylene emulsion (50% solid content), and 2 ml of Nafion solution with a concentration of 5 wt%, and stir ultrasonically for 30 minutes to obtain a catalyst anode slurry.

[0085] 2. Spraying

[0086] Take an area of 200cm 2 The carbon paper was placed on the porous bottom plate and fixed under negative pressure. The bottom plate was heated to 65°C, and then the above catalyst slurry was sprayed evenly on the porous bottom plate by ultrasonic spraying with argon as the carrier gas at a flow rate of 15ml / min.

[0087] 3. After spraying, leave it at room temperature for 40 minutes to dry.

[0088] 4. Put the electrode obtained in step 3 into a muffle furnace under the protection of nitrogen, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com