Cerenkov radiation source of surface plasma waves

A technology of surface plasmon and surface plasmon, applied in the direction of solid-state lasers, etc., can solve the problems of high working voltage, large volume, complex structure, etc., achieve narrow bandwidth and overcome the effect of wide radiation spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

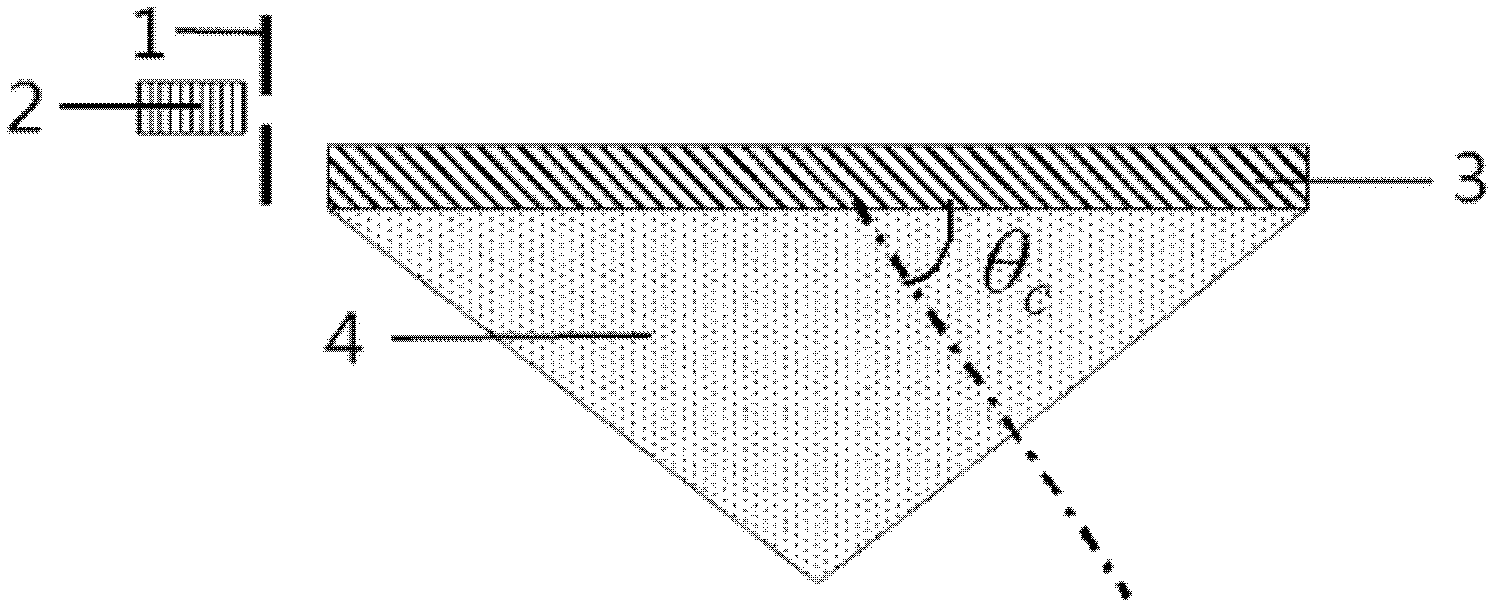

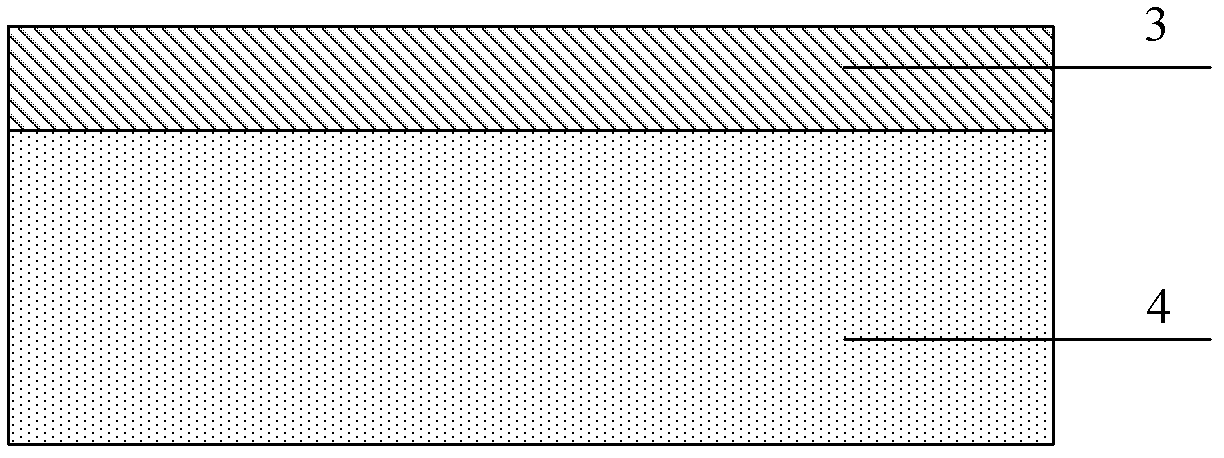

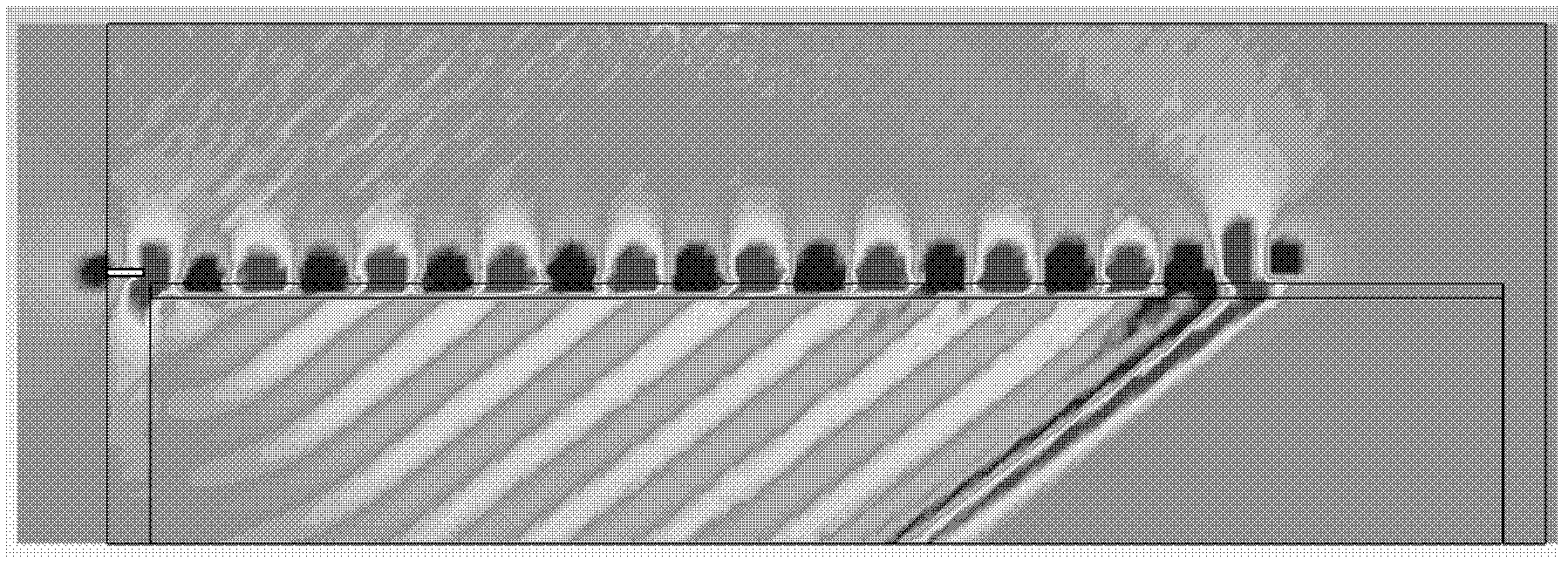

[0025] A source of surface plasmon Pocherenkov radiation, such as figure 1 , 2 As shown, it includes a metal baffle 1 , an electron gun 2 , a dielectric material layer 4 and a metal thin film layer 3 deposited on the surface of the dielectric material layer 4 . The electron beams emitted by the electron gun 2 pass over the surface of the metal thin film layer 3 to excite surface plasmon waves on the surface of the metal thin film layer 3 . The thickness of the metal thin film layer 3 is less than the skin depth δ of the surface plasmon wave in the metal material used in the metal thin film layer 3 m , so that the surface plasmon wave can pass through the metal thin film layer 3 and reach the dielectric material layer 4 . The ratio β of the moving speed of the electron beam emitted by the electron gun 2 to the speed of light in vacuum and the refractive index n of the dielectric material layer 4 satisfy the Cerenkov radiation condition: nβ>1, so that the surface plasma wave c...

Embodiment 2

[0029] Similar to Embodiment 1, the difference is that the material of the metal film layer 3 is gold, and the material of the dielectric material layer 4 is silicon, and the electrons of 100keV are also used to pass parallel to the direction of the gold film at a distance of 20nm from the upper surface of the gold film. Radiation with a frequency of 695 THz is excited.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com