Cobalt-based catalyst for Fischer Tropsch synthesis and preparation method thereof

A cobalt-based catalyst and Fischer-Tropsch synthesis technology, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, can solve the problems of low selectivity of effective products and poor abrasiveness, reduce synthesis costs, improve bonding energy, and facilitate the process The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

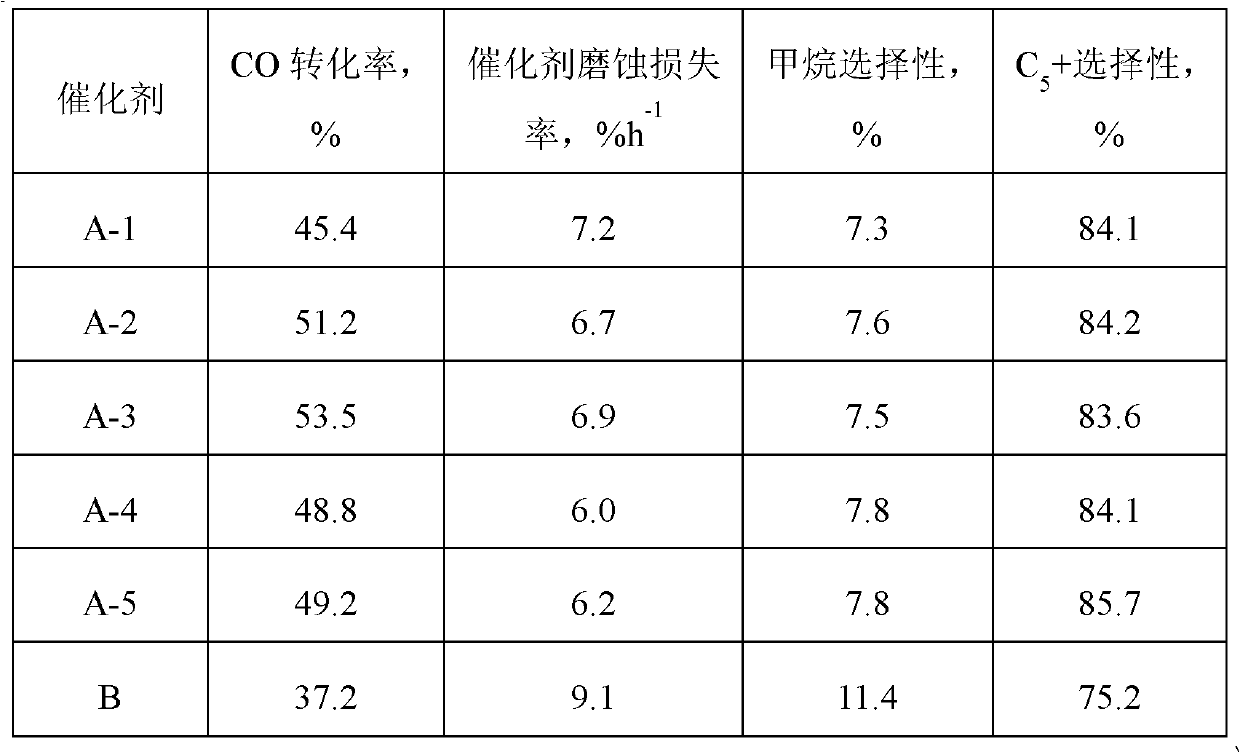

Examples

Embodiment 1

[0032] Add 4500g of deionized water to reactor A, and add 500g of γ-Al after turning on the stirring motor 2 o 3 Mix the powder, add hydrochloric acid and continue mixing until the pH value of the slurry is 5.0. Add 5500g of deionized water to reactor B, and add 500g of γ-Al2 o 3 powder, after stirring and mixing evenly, mix the slurry in AB two kettles evenly, heat to 80°C and let it stand for 1 hour, continue to stir, add alkaline silica sol, so that the mass ratio of silicon to aluminum is SiO 2 : Al 2 o 3 =20:80, continue to stir and mix evenly. Slowly add the prepared 0.1mol / L zirconium oxychloride solution into the above slurry. The temperature of the slurry is controlled at 25°C. Medium SiO 2 、Al 2 o 3 And 0.5% of the total mass of zirconium oxychloride. The obtained granular powder material was calcined at 650° C. for 6 hours, cooled and cooled for later use. Configure 1mol / L cobalt nitrate solution, 0.5mol / L lanthanum nitrate solution, 0.1mol / L ruthenium nit...

Embodiment 2

[0034] Add 2000g of deionized water into reaction kettle A, start the stirring motor, add 200g of pseudoboehmite and stir, add nitric acid and continue mixing until the pH value of the slurry is 6.5. Add 8100g deionized water and 900g pseudo-boehmite to reaction kettle B, stir and mix evenly, mix the slurry in AB two kettles evenly, heat to 90°C and let stand for 0.5 hours, continue stirring, add Sexual silica sol makes the ratio of silicon to aluminum to SiO 2 : Al 2 o 3 =30:70, continue to stir and mix evenly. Slowly add the prepared 0.2mol / L zirconium oxychloride solution into the above slurry. The temperature of the slurry is controlled at 20°C. Medium SiO 2 、Al 2 o 3 and 8% of the total mass of zirconium oxychloride, the obtained granular powder material was roasted at 300° C. for 10 hours, cooled and cooled for later use. Configure 0.1mol / L cobalt nitrate solution, 0.1mol / L cerium nitrate solution, 0.1mol / L potassium nitrate solution and 0.1mol / L ruthenium nitrate...

Embodiment 3

[0036] Add 1200g of deionized water to reactor A, and add 50g of γ-Al after turning on the stirring motor 2 o 3 Stir the powder, add hydrochloric acid and continue mixing until the pH value of the slurry is 0.5. Add 22800g deionized water to reactor B, and add 950g γ-Al 2 o 3 After stirring and mixing evenly, mix the slurry in AB two kettles evenly, heat to 40°C and let it stand for 5 hours, continue to stir, add neutral silica sol to make the mass ratio of silicon to aluminum to SiO 2 : Al 2 o 3 =10:90, continue to stir and mix evenly. Slowly add the prepared 0.3mol / L zirconium oxychloride solution into the above slurry. The temperature of the slurry is controlled at 15°C. Medium SiO 2 、Al 2 o 3 and 15% of the total mass of zirconium oxychloride, the obtained granular powder material was roasted at 800° C. for 3 hours, cooled and cooled for later use. Configure the cobalt nitrate solution of 0.5mol / L, the lanthanum nitrate solution of 0.5mol / L, the manganese chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com