Highly efficient beneficiation reagent for copper-nickel polymetallic sulphide ores

A beneficiation reagent and multi-metal technology, applied in flotation, solid separation, etc., can solve the problems that non-ferrous metals cannot be efficiently and comprehensively recycled, difficult to obtain satisfactory technical indicators for sorting, unsatisfactory metal recovery rate, etc., and achieve the effect of reagents Good effect, extended mine service life, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

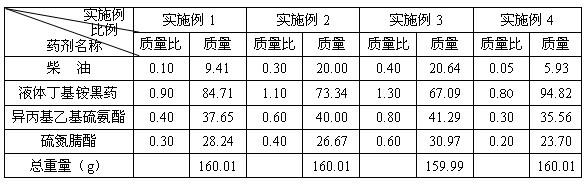

[0017] Application examples of embodiments 1 to 4

[0018] The ore used in Example 1 is a typical representative copper-nickel ore, wherein the metal minerals mainly include: chalcopyrite, pentlandite, purple sulfur nickel ore, pyrrhotite, pyrite, magnetite Ores, etc., followed by a small amount of chalcopyrite, black copper ore, hematite, ilmenite, etc. The main gangue minerals are serpentine, olivine, pyroxene, chlorite, etc.

[0019] The metal minerals in the ore used in embodiment 2 mainly include: pentlandite, chalcopyrite, goethite, pyrrhotite, pyrite, etc., followed by a small amount of magnetite, hematite, ferro-titanium The main gangue minerals are serpentine, chlorite, diopside, tremolite, etc.

[0020] The main metal minerals in the ore used in embodiment 3 are: chalcopyrite, pentlandite, purple sulfur nickel ore (a small amount), and other metal minerals are pyrrhotite, pyrite, marcasite, magnetite , galena, pyridoxite, etc., gangue minerals mainly include chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com