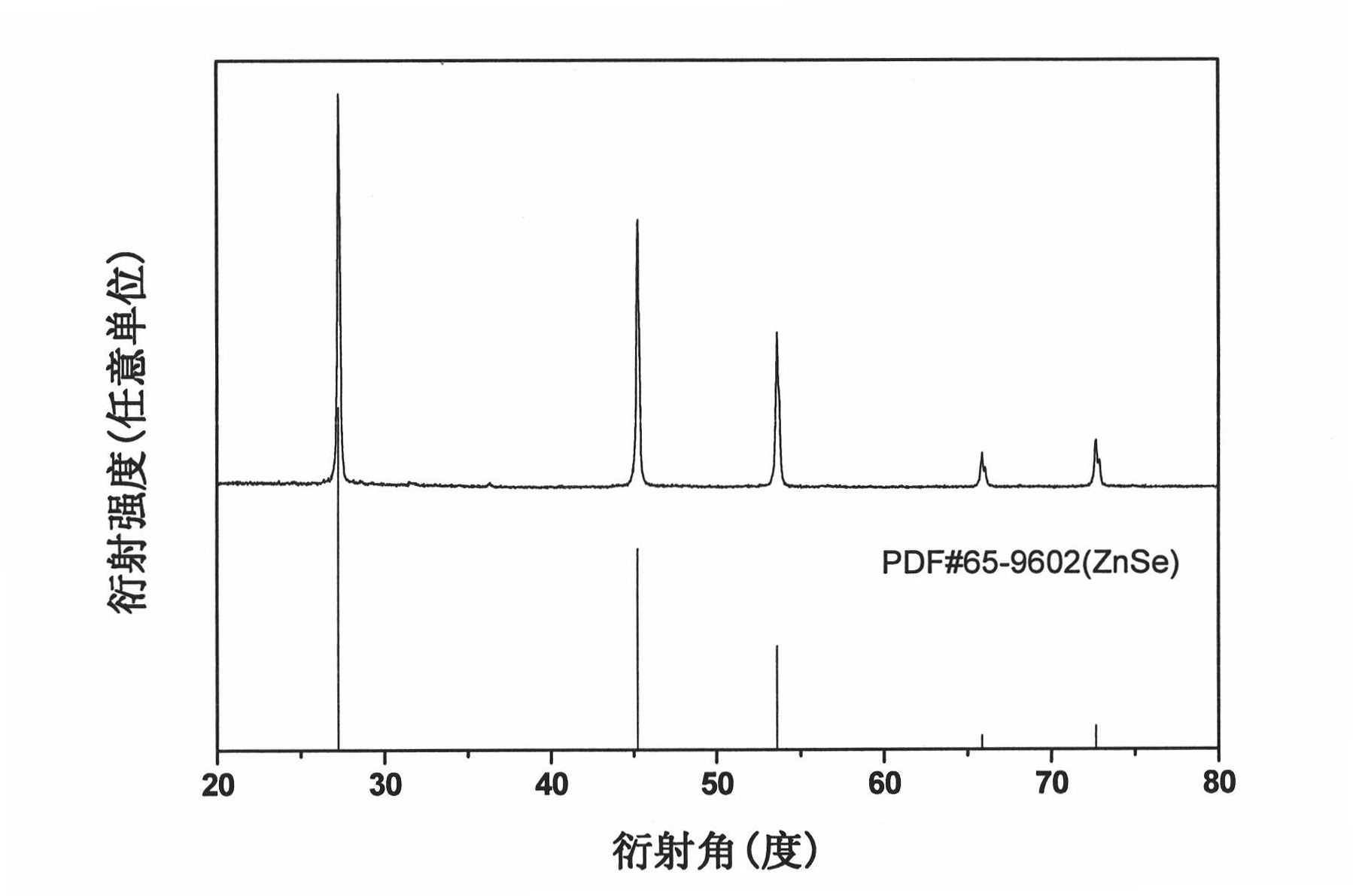

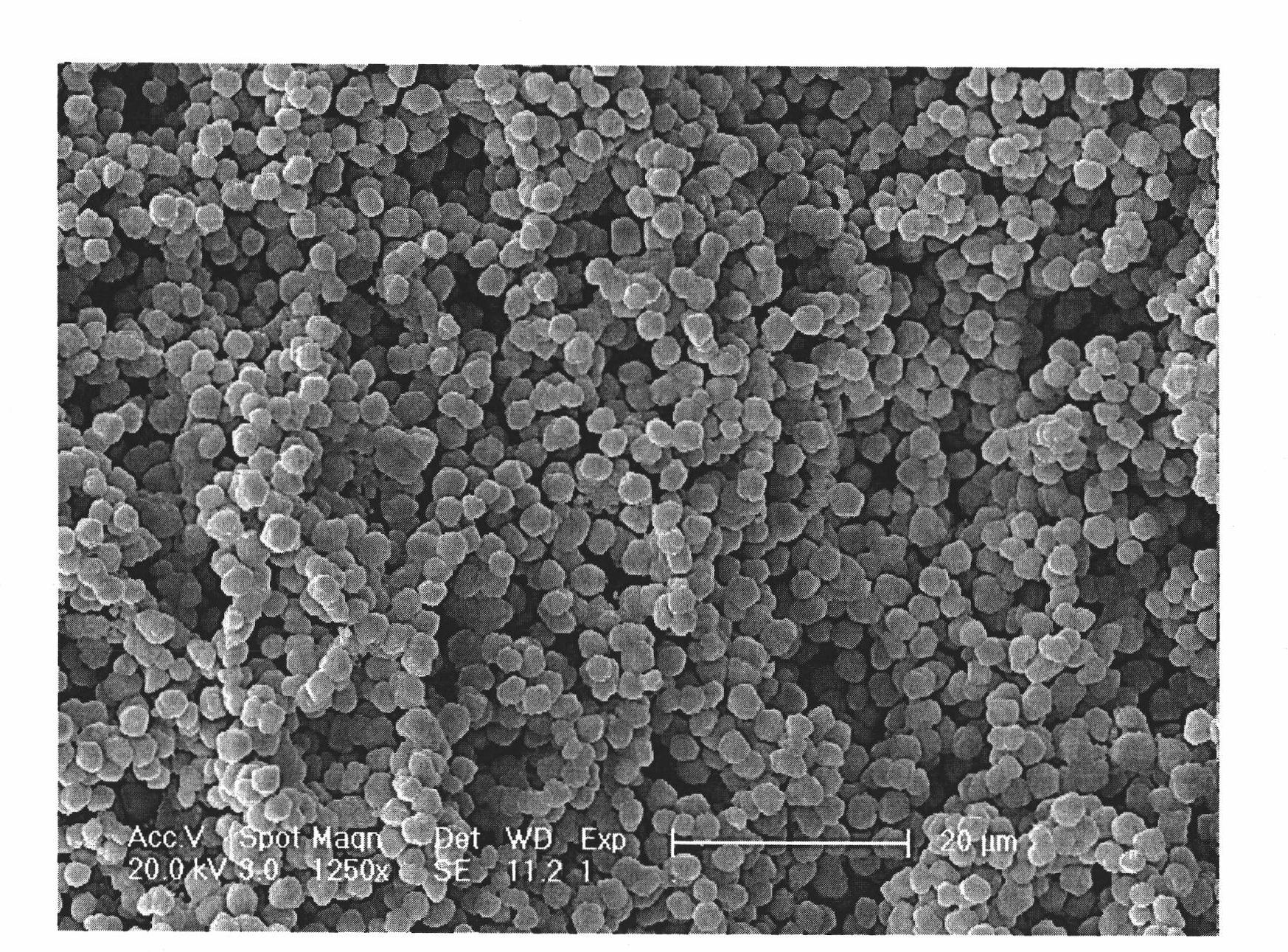

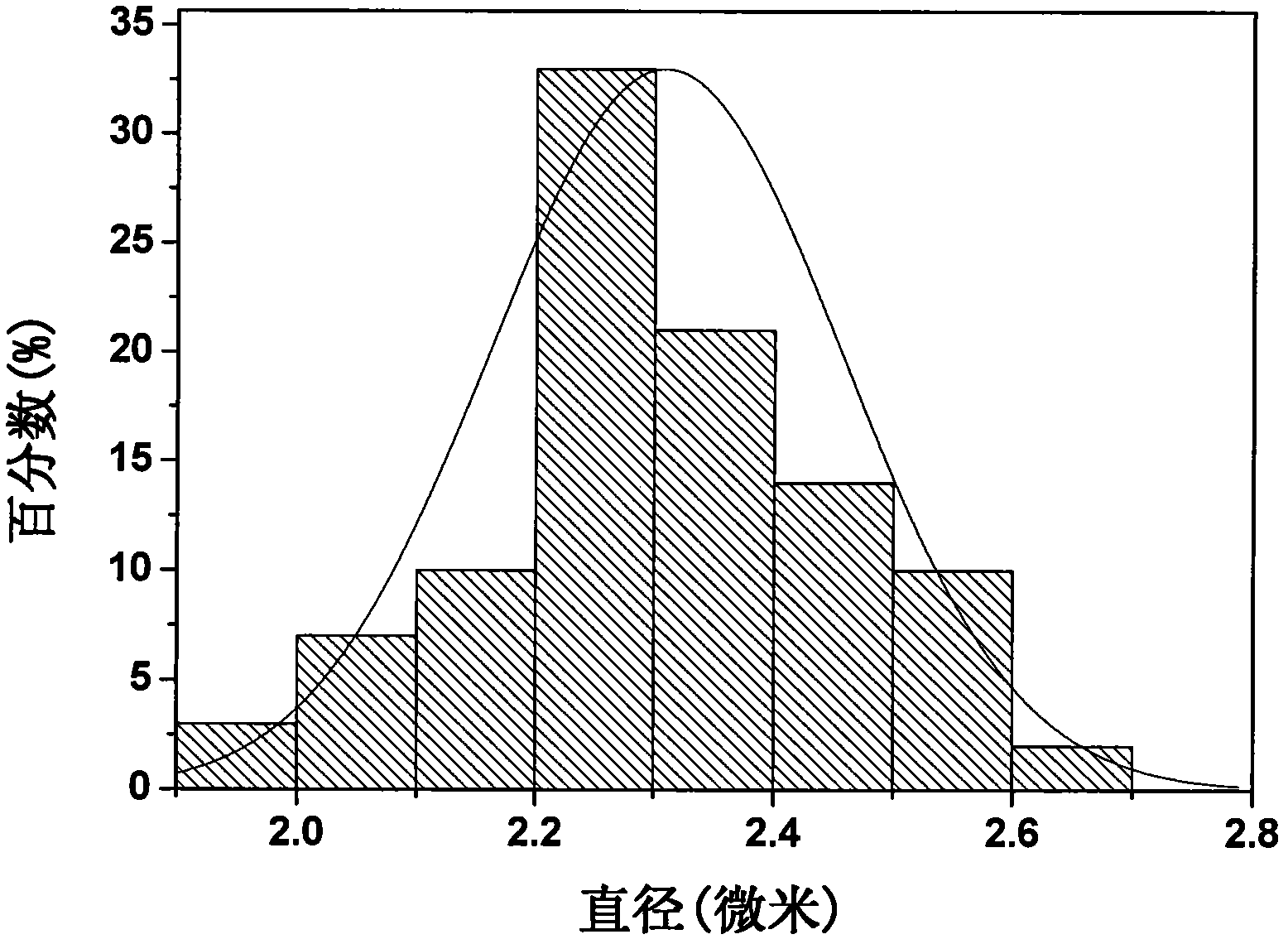

Method for preparing monodisperse zinc selenide particles

A monodisperse, zinc selenide technology for binary selenium/tellurium compounds, chemical characterization of fibers, chemical post-processing of rayon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Embodiment: take a certain amount of Zn (NO 3 ) 2 ·6H 2 O and PVP are added to an appropriate amount of DMF solvent, stirred magnetically at room temperature for 6 hours, and left to stand for 3 hours to form a spinning solution. The mass percentages of each component of the spinning solution are: zinc nitrate content 8%, PVP content 14%, the solvent DMF content is 78%; the prepared spinning solution is added to the liquid storage pipe of the spinning device for electrospinning, the inner diameter of the nozzle is 1mm, the angle between the nozzle and the horizontal plane is adjusted to 30°, and a 20kV direct current is applied Voltage, curing distance 22cm, room temperature 20~28℃, relative humidity 45%~65%, get PVP / Zn(NO 3 ) 2 Composite nanofibers, the PVP / Zn(NO 3 ) 2The composite nanofibers were heat-treated in a programmable temperature-controlled furnace with a heating rate of 1°C / min, kept at 600°C for 4 hours, then cooled down to 200°C at a rate of 1°C / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com