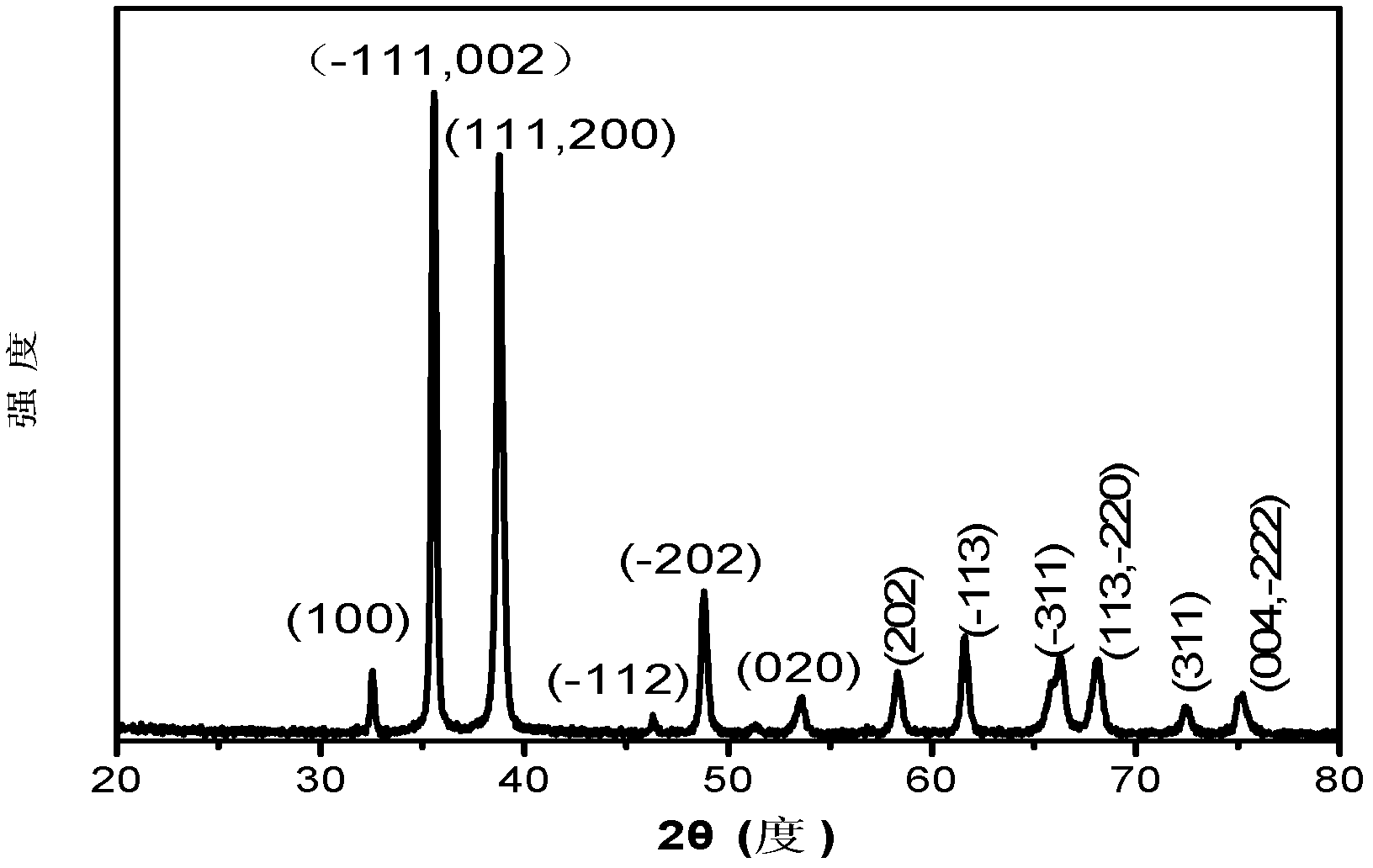

Method for preparing CuO nano-film

A nano-film, aqueous solution technology, applied in copper oxide/copper hydroxide and other directions, can solve problems such as inability to achieve, and achieve the effects of environmental protection cost, simple process, and excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] A method for preparing CuO nano film, the steps are as follows:

[0022] 1) Prepare 0.1M Cu(NO 3 ) 2 and 0.05M NaOH aqueous solution, drop the prepared NaOH aqueous solution into Cu(NO 3 ) 2 In solution, NaOH aqueous solution and Cu(NO 3 ) 2 The volume ratio of the aqueous solution is 1:1, the water bath is magnetically stirred, the reaction temperature is 90°C, and the reaction time is 1 hour, and a blue flocculent precipitate is obtained;

[0023] 2) Wash the above precipitate with deionized water, centrifuge, dry and grind to obtain a blue powder;

[0024] 3) Put the above-mentioned blue powder into the crucible, and bake it in a muffle furnace at 400°C for 1 hour to obtain black CuO powder;

[0025] 4) The above-mentioned black CuO powder was dissolved in n-hexane at a dosage ratio of 2 mg / ml, and after ultrasonic and centrifugal separation, a uniformly dispersed CuO solution was obtained;

[0026] 5) Spin-coat the above-mentioned CuO solution on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

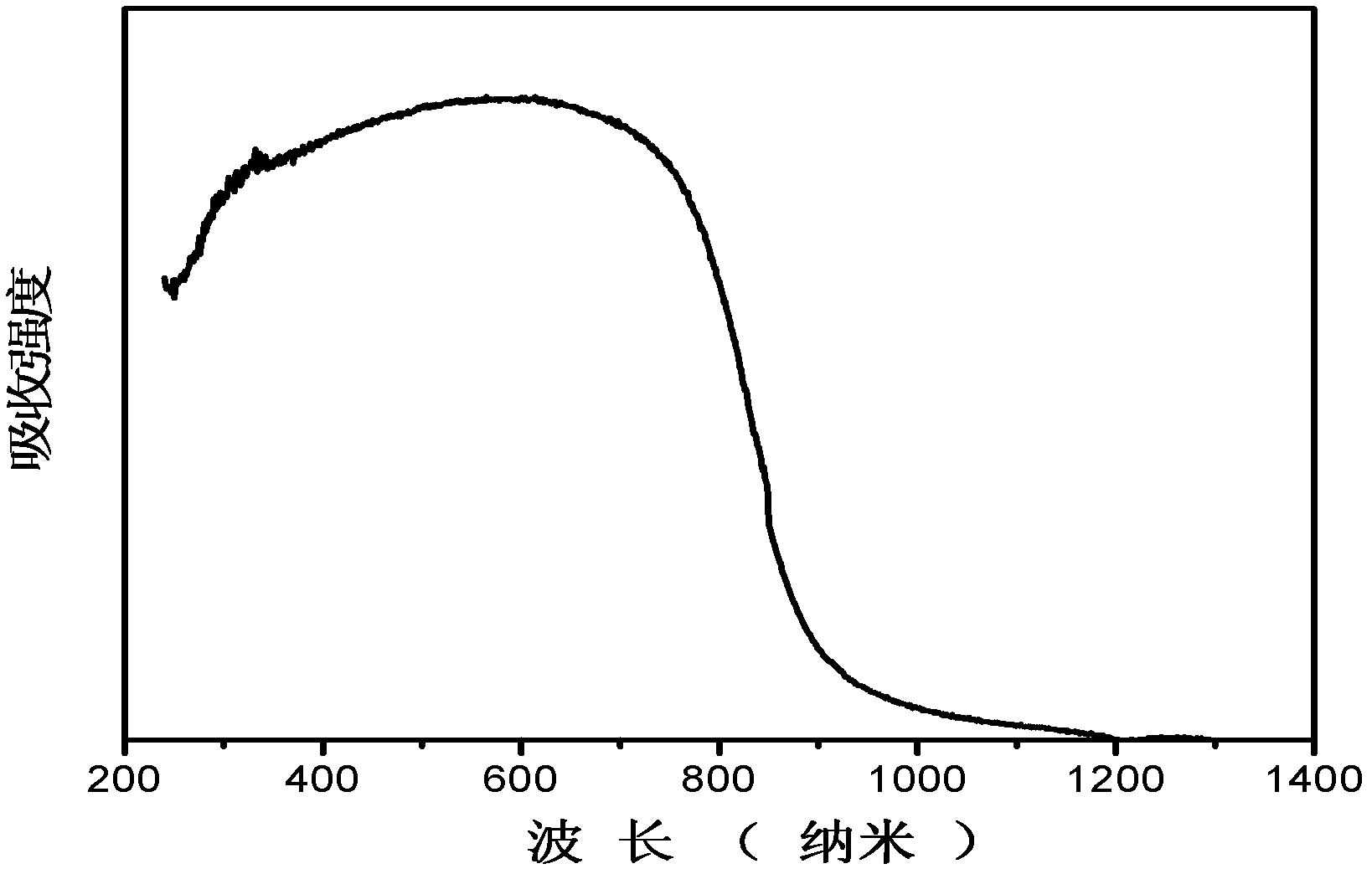

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com