P type doped ZnSxSe1-x nano material and preparation method thereof

A technology of nanomaterials and doping sources, applied in the field of P-type doped ZnSxSe1-x nanomaterials and its preparation, can solve problems such as difficulties and achieve the effect of adjustable band gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

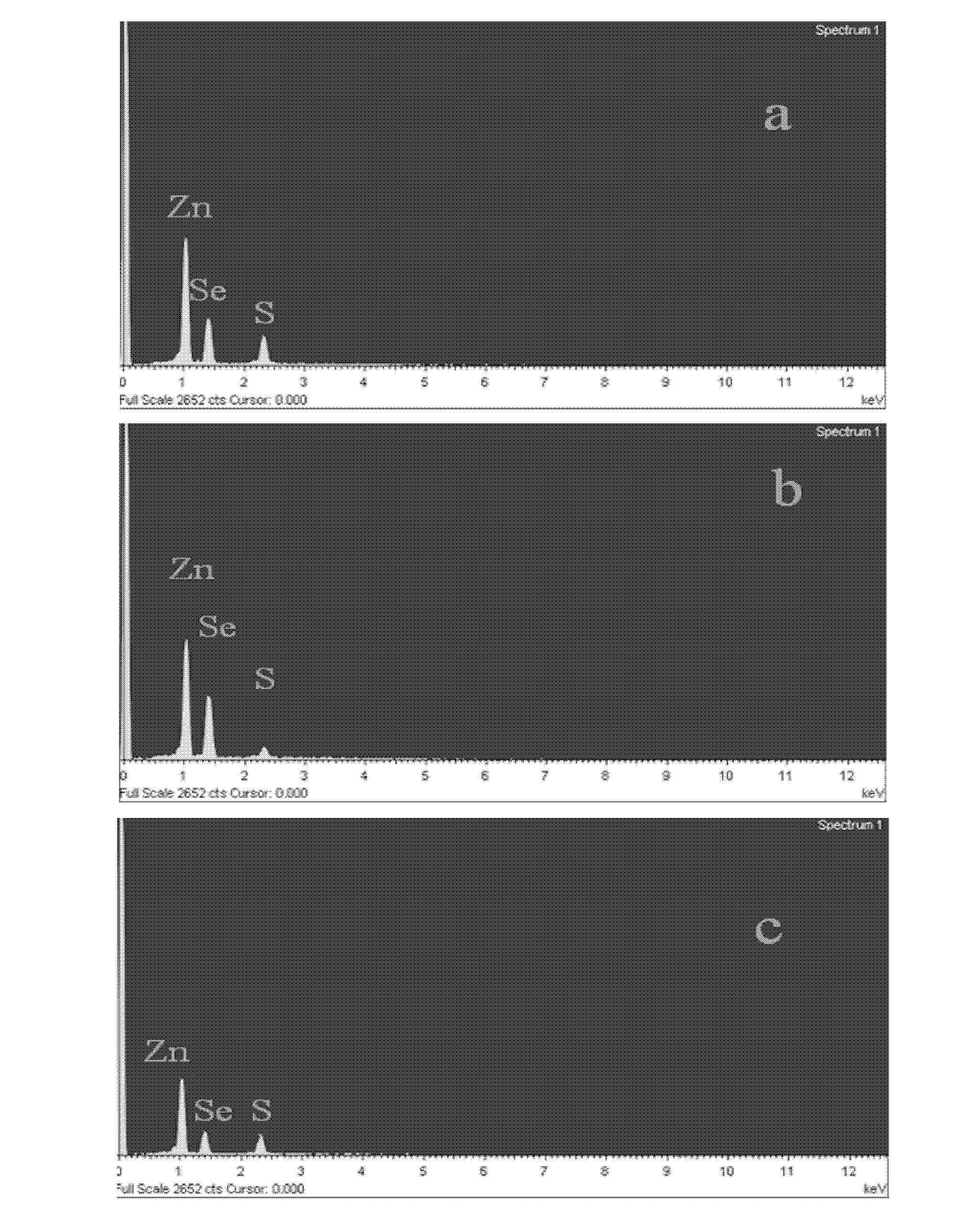

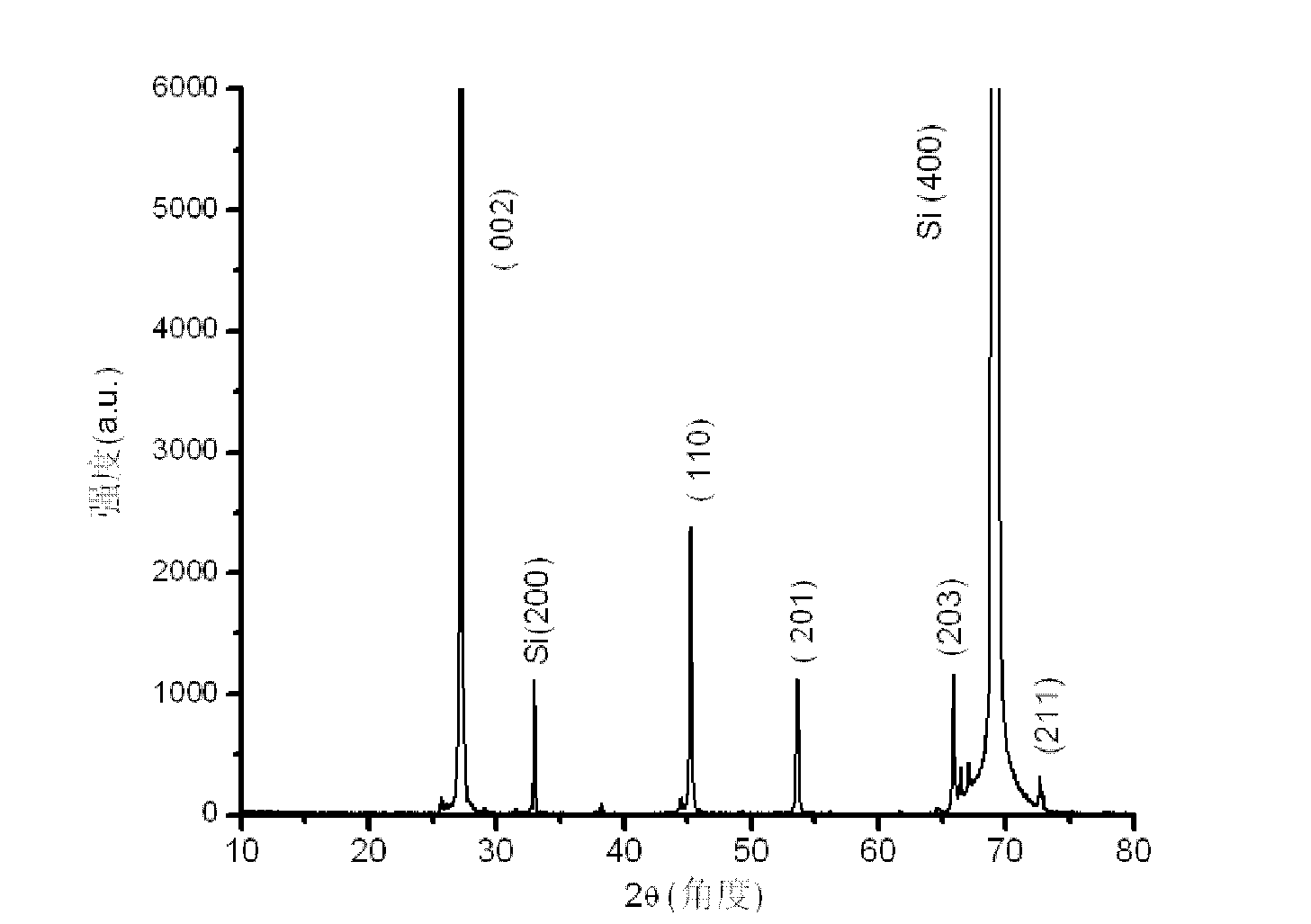

Embodiment 1

[0037] 1. Weigh 0.14g of ZnSe powder with a purity of ≥99.99% and 0.097g of ZnS powder with a purity of ≥99.99%, respectively, grind and mix them and add them to the porcelain boat.

[0038] 2. A gold-evaporated silicon wafer with a gold layer thickness of 10 nm was prepared by using an electron beam evaporation process according to a conventional method, and the gold-evaporated silicon wafer was used as a deposition substrate.

[0039] 3. Put the porcelain boat and the deposition substrate into a quartz tube in sequence, and then put the quartz tube into the horizontal tube furnace. The specific positions are: the porcelain boat is located at the heating source, and the deposition substrate is located 13 cm downstream of the heating source. After the quartz tube is sent in, the furnace body is sealed and vacuumized, and after the vacuumization is completed, 85 sccm of argon-hydrogen mixture (hydrogen accounts for 5vt%) and 15 sccm of NH are introduced into the furnace body. ...

Embodiment 2

[0041] The preparation method of this embodiment is the same as that of Example 1, except that the gas flow rate of the argon-hydrogen mixture is 70 sccm, and the NH 3 The gas flow rate is 30sccm to obtain P-type doped ZnS 0.5 Se 0.5 nanomaterials.

Embodiment 3

[0043] The preparation method of this embodiment is the same as that of Example 1, except that the ZnSe powder weighs 0.196g, and the ZnS powder weighs 0.058g to obtain P-type doped ZnS 0.3 Se 0.7 nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com