Lifting type wireless control turnover throwing machine

A technology of wireless control and turning and throwing machine, which is applied in the direction of two-dimensional position/channel control, organic fertilizer, organic fertilizer preparation, etc., which can solve the problems of unfavorable occupational health of drivers, large mechanical power loss, and large manual labor. , to achieve the effect of improving safety and quality, overcoming large mechanical loss and small amount of manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

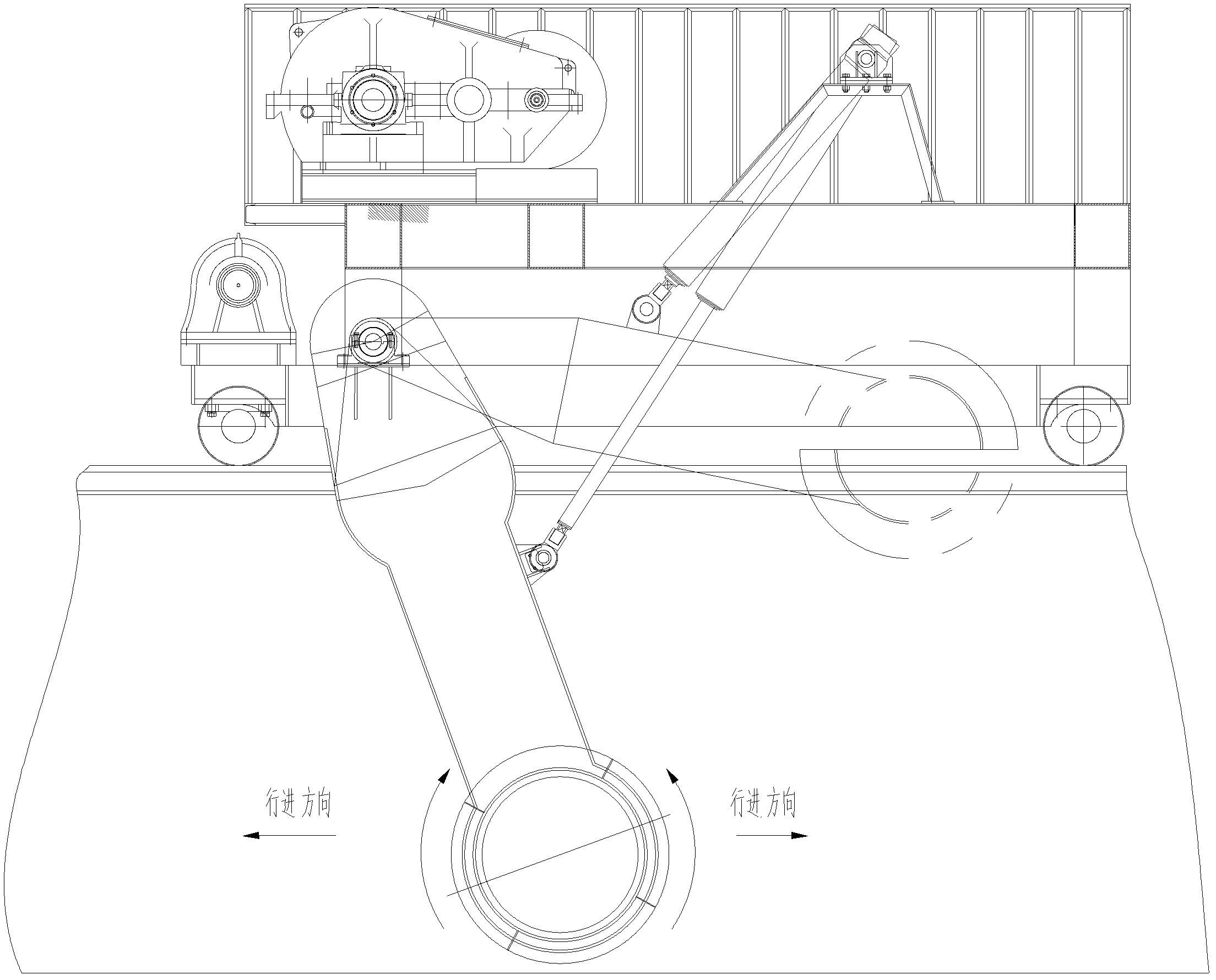

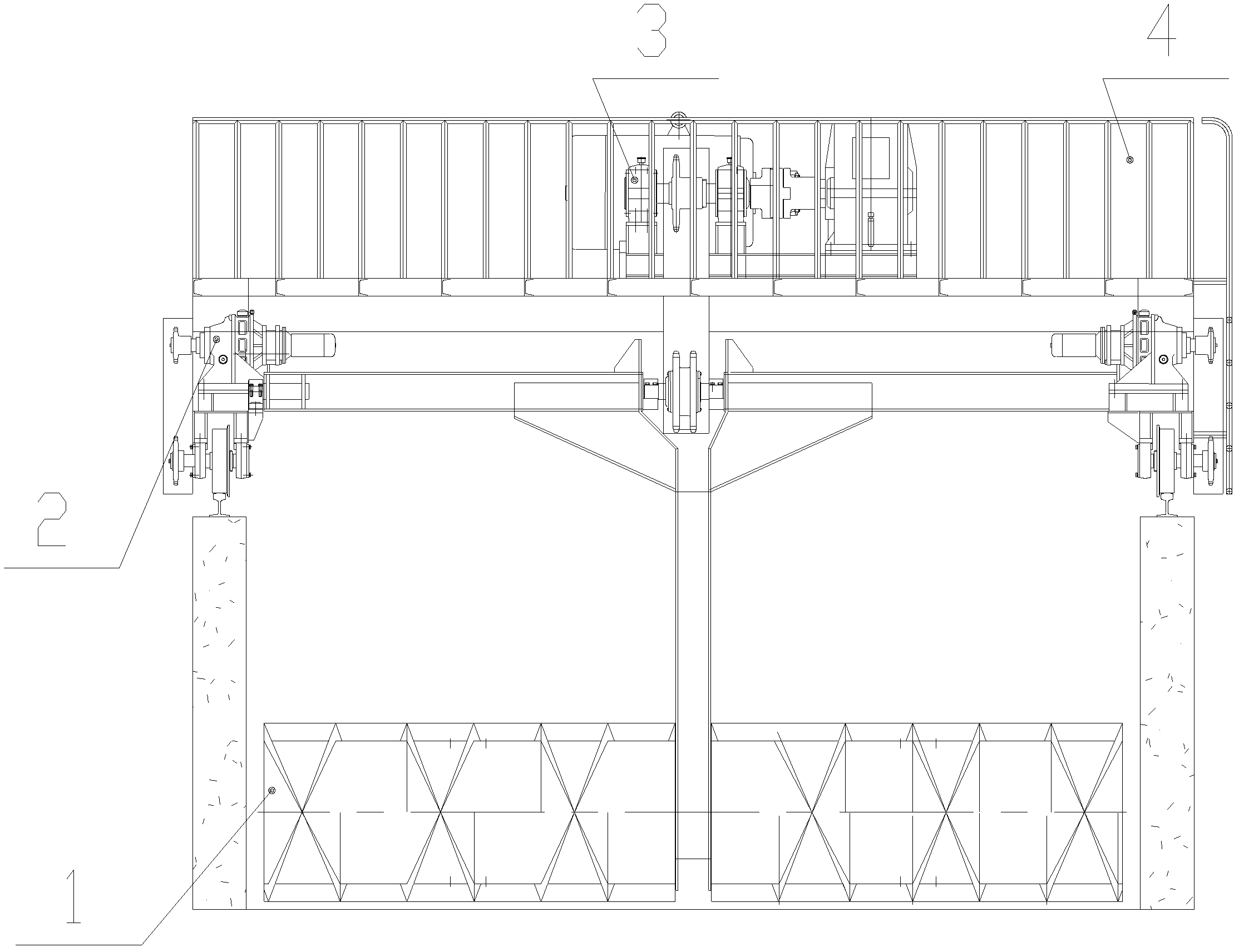

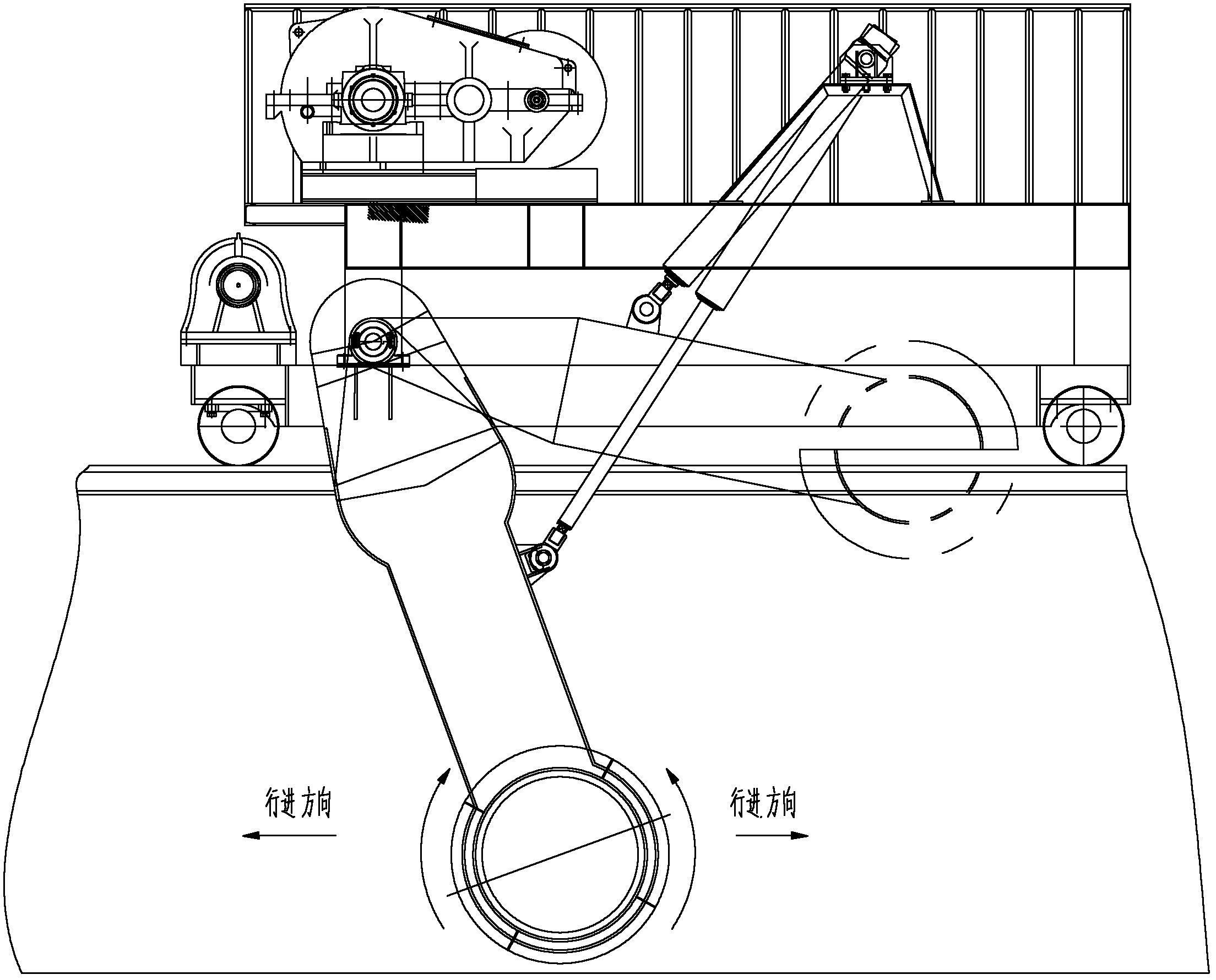

[0033] According to an embodiment of the present invention, a lifting type wireless control turning and throwing machine is provided. Such as figure 1 and figure 2 As shown, this embodiment includes a remote control host, a trackless or track-type lifting type turning machine body, a PLC module, an industrial wireless communication module and a PLC module that are arranged on the lifting type turning machine body, and are used for each purpose. A power supply module that supplies power to electrical equipment and is electrically connected to each electrical equipment.

[0034] Here, the PLC module is used to collect the action signal of the lift-type turning and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com