Method for extracting phenolic compounds from biological oil

A technology for phenolic substances and bio-oil, which is applied in chemical instruments and methods, preparation of organic compounds, and ether separation/purification, etc., can solve the problems of difficult extraction, inability to separate phenolic substances, and no public reports, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

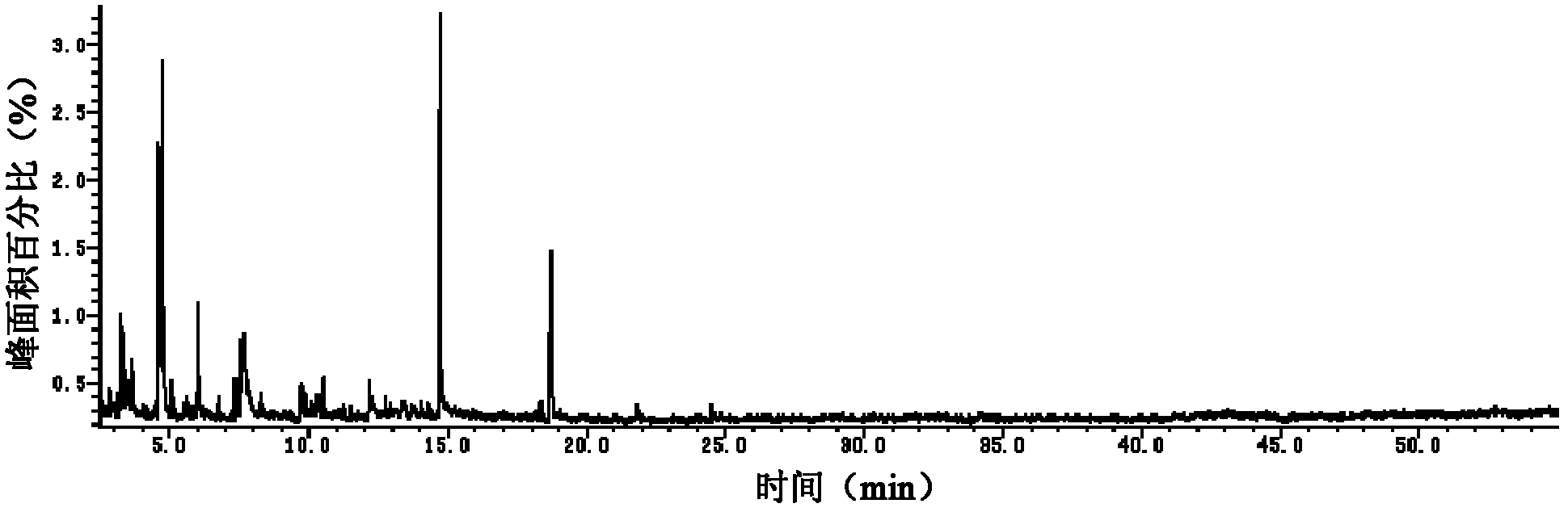

[0034] The bio-oil prepared by rapid cracking of pine sawdust was distilled, and the distillate at 120-260° C. contained dozens of mixed substances, as shown in Table 1, wherein the content of phenolic substances was 24.17% (molar ratio). Take 100ml of bio-oil distillate, drop into calcium chloride solution containing 0.3mol calcium ions, drop into NaOH solution to adjust the pH value to 8.5, shake and stir evenly in a water bath at 25°C, a complex precipitate is formed, after vacuum filtration , after the precipitate was acidified and replaced by 2.5mol / L hydrochloric acid solution, 10ml of ethyl acetate was added dropwise for extraction, the upper layer solution was extracted, and the extractant was distilled to finally obtain 0.4g of phenolic substances.

[0035] The sample is injected into GC-MS, and the composition of the bio-oil extract obtained by analysis is shown in Table 2 and figure 2 shown.

[0036] Table 2

[0037] peak number

[0038] Note: CaCl 2 A...

Embodiment 2

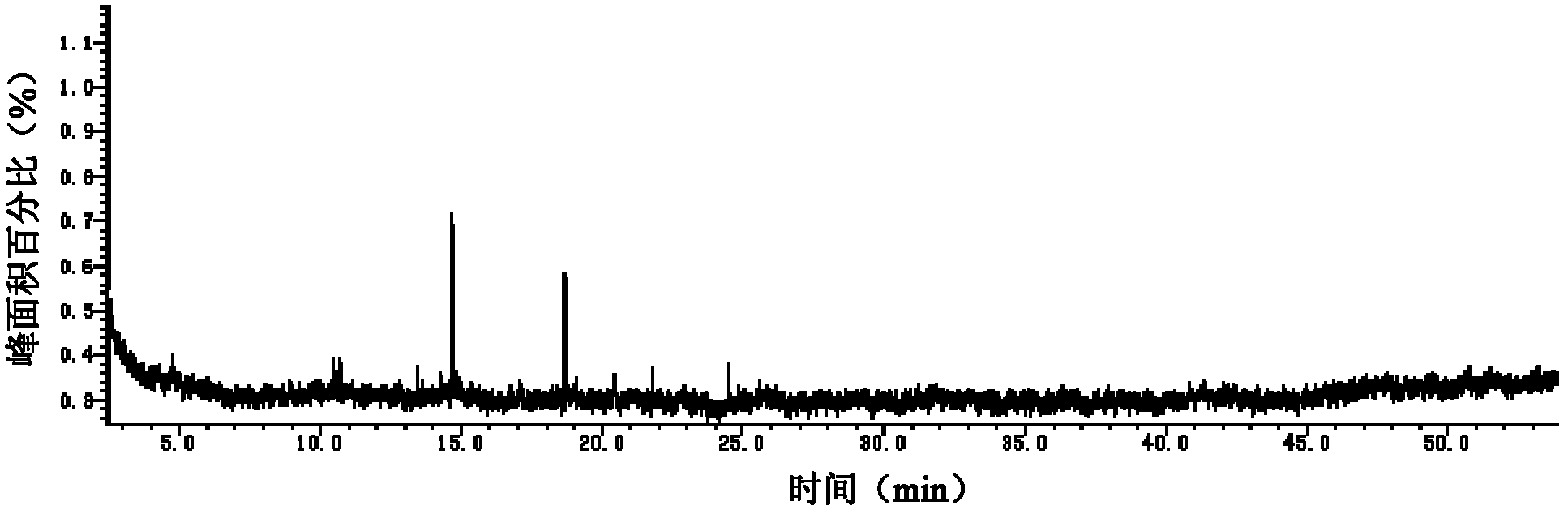

[0040] Similar to Example 1, take 100ml of bio-oil distillate, drop into calcium chloride solution containing 0.3mol calcium ions, drop into NaOH solution to adjust the pH value to 8.5, oscillate and stir evenly in a 75°C water bath, and complexes precipitate After vacuum filtration, the precipitate was acidified and replaced by 2.5mol / L hydrochloric acid solution, extracted by dropping 10ml of ethyl acetate, and the upper layer solution was extracted. After distilling the extractant, 2.8g of phenolic substances were finally obtained, indicating that In the solution treated in a 75°C water bath, the extraction rate of phenolic substances is increased by 6-7 times. The sample is injected into GC-MS, and the composition of the bio-oil extract obtained by analysis is shown in Table 3 and image 3 shown.

[0041] table 3

[0042] peak number

[0043] Note: CaCl 2 As a precipitant, 75 ° C extraction temperature, ethyl acetate as an extractant.

Embodiment 3

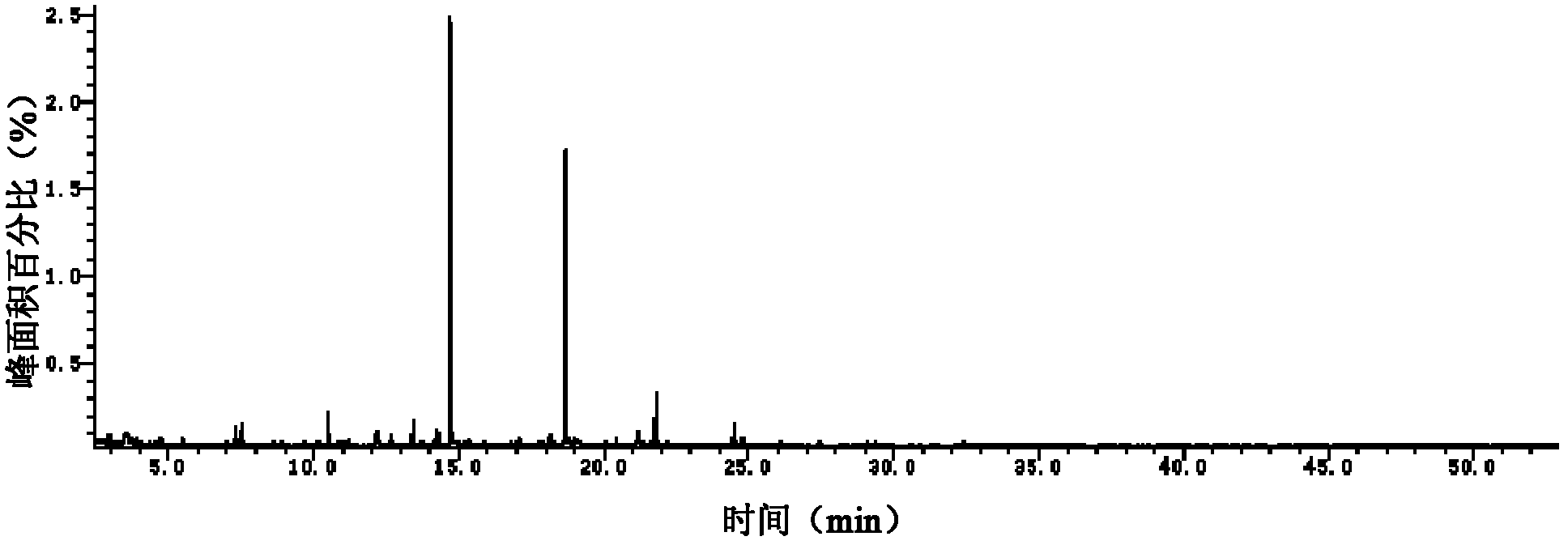

[0045] Similar to Example 1, take 100ml of bio-oil distillate, drop into magnesium chloride solution containing 0.3mol of magnesium ions, drop into NaOH solution to adjust the pH value to 8, oscillate and stir evenly in a 75°C water bath, and a complex precipitate is formed. After vacuum filtration, the precipitate was hydrolyzed and replaced by 1.5 mol / L hydrochloric acid solution, then extracted with 10 ml of ethyl acetate dropwise, the upper layer solution was extracted, and the extractant was distilled to finally obtain 3.4 g of powdered phenolic substances. The sample was injected into GC-MS, and the composition of the obtained bio-oil extract was shown in Table 4.

[0046] Table 4

[0047] peak number

[0048] Note: MgCl 2 As a precipitant, 75 ° C extraction temperature, ethyl acetate as an extractant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com