Extraction method of sapindus saponin

A technology of sapindus saponin and extraction method, which is applied in the direction of steroids, organic chemistry, etc., can solve the problems that affect the normal operation of the unit, the process of solvent residue, the large consumption of solvent, etc., and achieve the improvement of product enrichment ratio , Shorten the water extraction time, the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

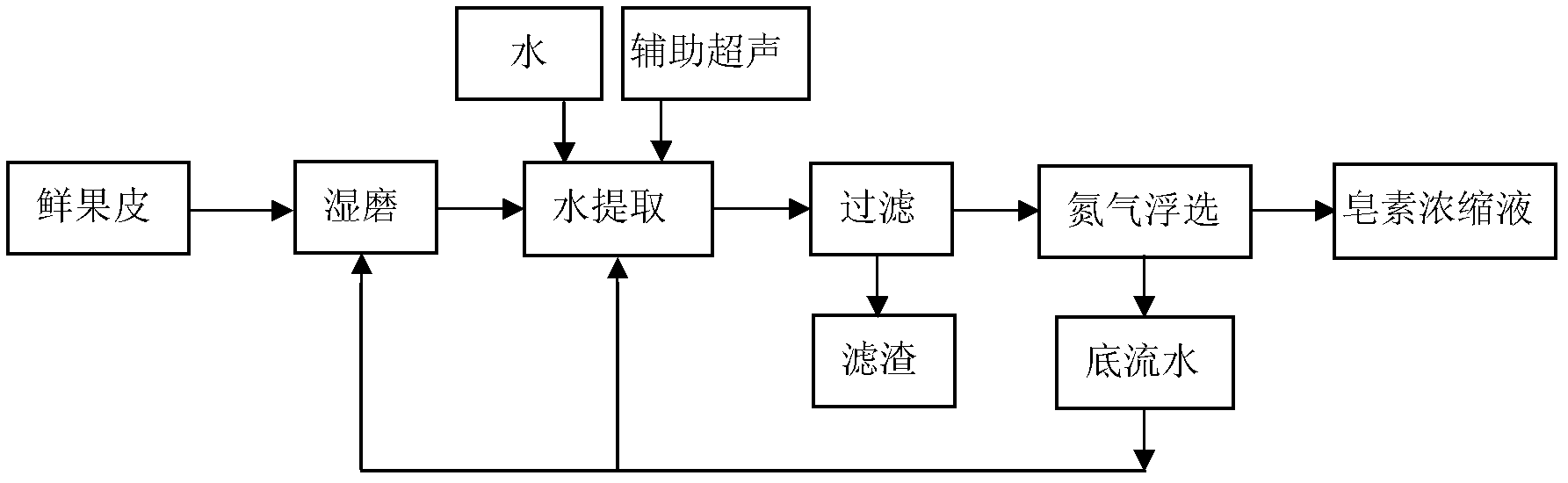

Method used

Image

Examples

Embodiment 1

[0023] The Sapindus fruit peel is directly subjected to water extraction, the material-water ratio (mass ratio) of the peel and water is controlled at 1:4 during extraction, and the extraction temperature is 40°C; assisted ultrasonic extraction, ultrasonic frequency 20KHz, ultrasonic intensity 20W / cm2, ultrasonic time 10min; water extraction time 60min. Direct nitrogen flotation of the water extract, the separation and concentration of Sapindus saponin is carried out in a flotation tank, the flotation temperature is 35°C, the nitrogen purity is 99%, and the volume ratio of nitrogen in the flotation tank to the water extract is 0.6. The water circulation at the bottom of the flotation tank can also be used for the extraction of Sapindus saponin. The enrichment ratio of Sapindus saponin is 3.13, the yield of Sapindus saponin is 35.3%, and the purity of sapinin is 71.5%.

Embodiment 2

[0025]Wet mill fresh Sapindus sapindus peel with a disk mill, the concentration of the peel is 20%, the pulp is vibrated and screened, the sieve hole diameter is Φ2mm, and the sieved coarse residue is sent back to the disk mill for re-grinding. The undersieve enters the saponin water extraction, the material-water ratio (mass ratio) of the peel and water is controlled at 1:4 during extraction, and the extraction temperature is 40°C; ultrasonic extraction is assisted, the ultrasonic frequency is 20KHz, the ultrasonic intensity is 20W / cm2, and the ultrasonic time is 10min ; Water extraction time 60min. Nitrogen flotation, the separation and concentration of Sapindus saponin is carried out in a flotation cell, the flotation temperature is 35°C, the nitrogen purity is 99%, and the volume ratio of nitrogen in the flotation cell to water extract is 0.6. The water circulation at the bottom of the flotation tank can also be used for wet grinding and saponin extraction of Sapindus frui...

Embodiment 3

[0027] The Sapindus fruit peel is directly subjected to water extraction, the material-water ratio (mass ratio) of the peel and water is controlled at 1:4 during extraction, and the extraction temperature is 40°C; assisted ultrasonic extraction, ultrasonic frequency 20KHz, ultrasonic intensity 20W / cm2, ultrasonic time 10min; water extraction time 60min. The extract was filtered by a filter press, and the moisture content of the filter residue was 39%. Nitrogen flotation, the separation and concentration of Sapindus saponin is carried out in a flotation cell, the flotation temperature is 35°C, the nitrogen purity is 99%, and the volume ratio of nitrogen in the flotation cell to water extract is 0.6. The water circulation at the bottom of the flotation tank can also be used for the extraction of Sapindus saponin. The enrichment ratio of Sapindus saponin is 3.13, the yield of Sapindus saponin is 32.5%, and the purity of sapinin is 86.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com