Solid catalyst component for olefin polymerization and catalyst

A solid catalyst and olefin polymerization technology, applied in the field of olefin polymerization, can solve the problems of insufficient wide molecular weight distribution and poor processability of polypropylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

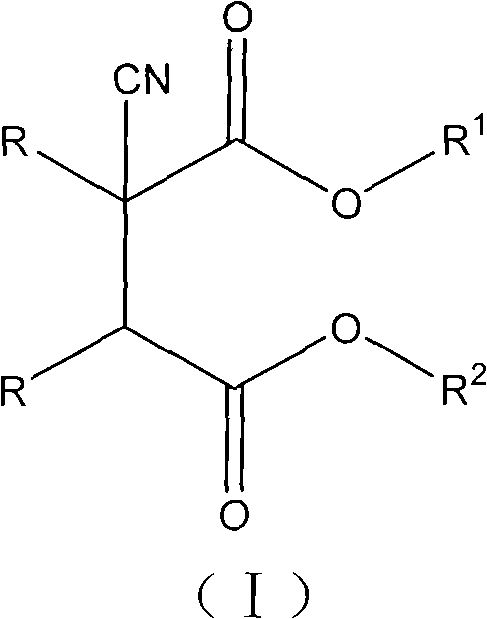

Image

Examples

Embodiment 1

[0048] 2, the preparation of 3-diisopropyl-2-dicyanodiethyl succinate (referred to as "JS" in Table 1): according to the disclosed embodiment 1 method of International Patent Application No. PCT / CN2010 / 000202 , expand the consumption of reactant and solvent in Example 1 by 10 times, and separate and purify 2,3-diisopropyl-2-dicyanodiethyl diethyl ester crude product with a chromatographic column filled with silica gel, Change to vacuum distillation for separation and purification, and collect 124-127°C fractions under the pressure of 110-120Pa. The infrared analysis of the product is consistent with the diethyl 2,3-diisopropyl-2-dicyanosuccinate obtained in Example 1 disclosed in PCT / CN2010 / 000202.

[0049] IR (cm -1 ): 2979, 2881, 2246, 1733, 1469, 1394, 1371, 1299.6, 1141.

Embodiment 2

[0051] (1) Preparation of catalyst components

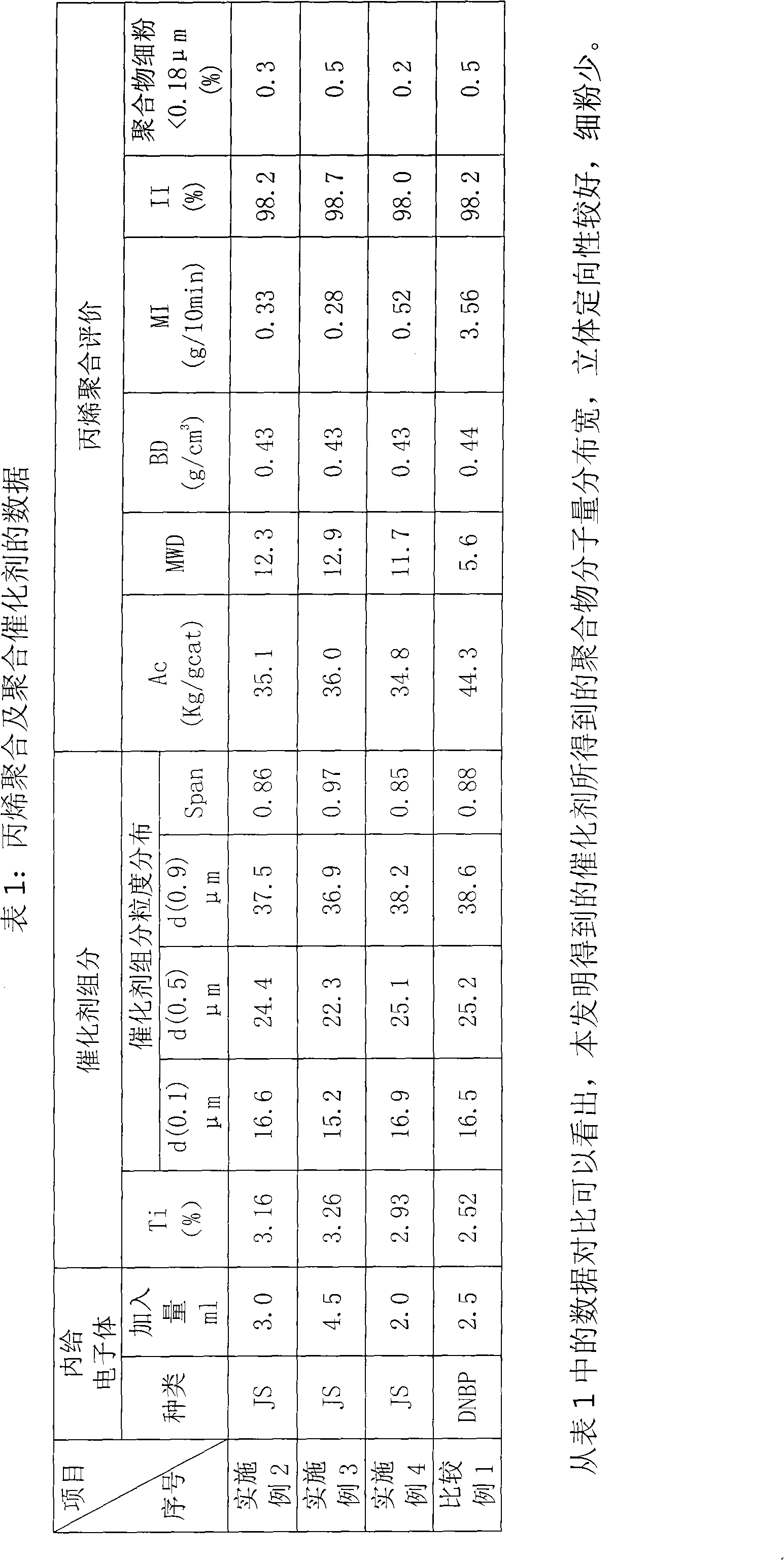

[0052] Choose magnesium alkoxide (d (0.5) is 26.4 μm, Span value is 0.85) 10g and toluene 50ml, the 2,3-diisopropyl-2-dicyano-diethyl succinate prepared by the method of embodiment 1 (abbreviated as "JS" in Table 1) 3.0ml is prepared into a suspension; in a 300ml reaction kettle repeatedly replaced by high-purity nitrogen, add 10ml of toluene and 90ml of titanium tetrachloride, heat up to 80°C, and then prepare Add the suspension into the kettle, keep the temperature constant for 1 hour, continue to heat up to 110°C, keep the temperature constant for 2 hours, and then filter the liquid clean. Then add a mixture of 120ml of toluene and 30ml of titanium tetrachloride and raise the temperature to 110°C and stir it for 1 hour, treat it like this 3 times, filter off the liquid, wash the obtained solid 4 times with 150ml of hexane, filter off the liquid and dry to obtain solid catalyst components.

[0053] (2) Olefin polymerization ...

Embodiment 3

[0057] Except in the preparation (1) of catalyst component, the diethyl 2,3-diisopropyl-2-dicyano succinate (abbreviated as " JS " in Table 1) prepared by the method of Example 1 Except that add-on is changed into 4.5ml, other is with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com