Thermal insulation composite coating and preparation method as well as application thereof

A composite coating and coating technology, applied in the field of materials and coatings, to achieve good ability to reflect heat and sunlight, improve refractive index, and good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

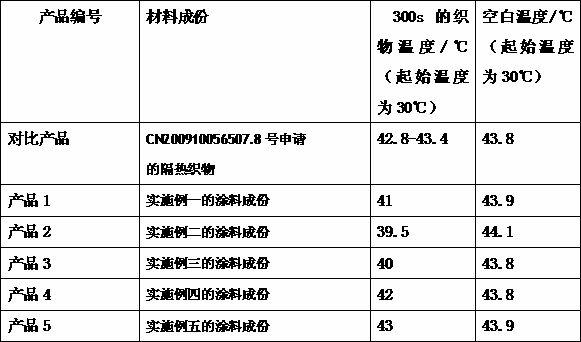

Examples

Embodiment 1

[0025] Preparation of titanosilicate complexes:

[0026] Take tetrabutyl titanate, anhydrous ethanol, distilled water, and glacial acetic acid, prepare materials in a volume ratio of 2:4:1:1, mix tetrabutyl titanate C 16 H 36 O 4 Ti was added to half anhydrous ethanol, stirred in an ice-water bath for 5 minutes, then slowly added dropwise the other half of anhydrous ethanol, distilled water and glacial acetic acid to form a mixed solution, and stirred for 1 h to obtain a transparent sol; 8 (H 2 O) 4 [Si 6 O 16 ] 2 (OH) 4 ·8H 2 O powder stirred into sol; Mg 8 (H 2 O) 4 [Si 6 O 16 ] 2 (OH) 4 ·8H 2 The particle size of O powder is 50-90 microns; sol and Mg 8 (H 2 O) 4 [Si 6 O 16 ] 2 (OH) 4 ·8H 2 The weight ratio of O is 1:1-2; then placed in the atmosphere for 4 hours, then heated to 600°C at a rate of 100°C / h in a heat treatment furnace, kept at a constant temperature for 6 hours, and then cooled to room temperature with the furnace to obtain a titanium-c...

Embodiment 2

[0029] The preparation of the titanium-containing silicate composite is the same as that in Example 1.

[0030] Preparation of coating: by weight percentage: ethanol 20%; dioctyl phthalate 10%; phosphate ester 0.9%; titanium-containing silicate composite 20%, polyacrylic resin 12%, and the rest are polyurethane, and the ingredients are mixed , stir evenly in the container to form the thermal insulation composite coating.

Embodiment 3

[0032] The preparation of the titanium-containing silicate composite is the same as that in Example 1.

[0033] Preparation of coating: by weight percentage: ethanol 25%; dioctyl phthalate 7%; phosphate ester 0.8%; titanium-containing silicate composite 170%, polyacrylic resin 9%, and the rest are polyurethane, and the ingredients are mixed , stir evenly in the container to form the thermal insulation composite coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com