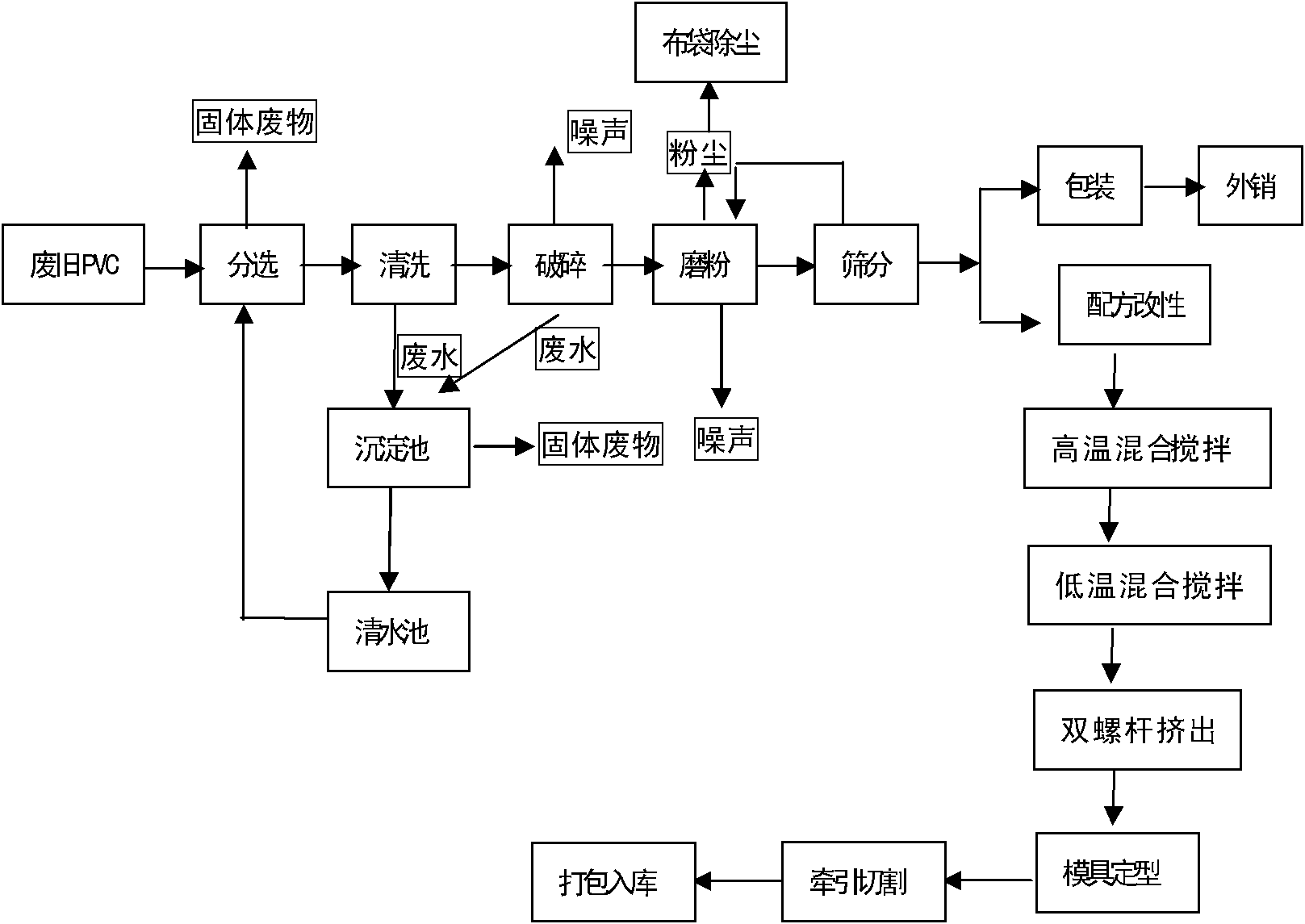

Bamboo shred waste regenerated composite plastic plate and production technology thereof

A composite plastic board and waste plastic technology, which is applied in the field of recycled composite plastic board and its production process, can solve the problems of unsatisfactory smoothness and color uniformity of carbon fiber plastic boards, poor fluidity of composite materials, high carbon fiber filling, etc., to achieve The production of raw materials has a wide range of sources, good thermal stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Embodiment 1: The technical solution of the present invention relates to a kind of bamboo scrap waste regenerated composite plastic board, and its composition comprises the raw material of following weight ratio: 100 parts of waste PVC powder, 20-30 parts of bamboo scrap powder, composite stabilizer 5- 7 parts, processing aid ACR 3-5 parts, impact modifier CPE 5-8 parts, lubricant 0.8-1 part, filler 8-10 parts, colorant 0.1-0.2 parts, anti-ultraviolet agent 0.01-0.015 parts share.

[0036] The composite stabilizer refers to the mixture of tri-salt, di-salt and metal soap in the reaction system with nascent grain size and various lubricants by using the symbiotic reaction technology, and the processing aid refers to the acrylic acid series Resin, impact modifier refers to chlorinated polyethylene, lubricant refers to paraffin and stearic acid, filler refers to CaCO 3 , the coloring agent refers to a pigment, and the anti-ultraviolet agent refers to 2-hydroxy-4-methoxyben...

Embodiment 2

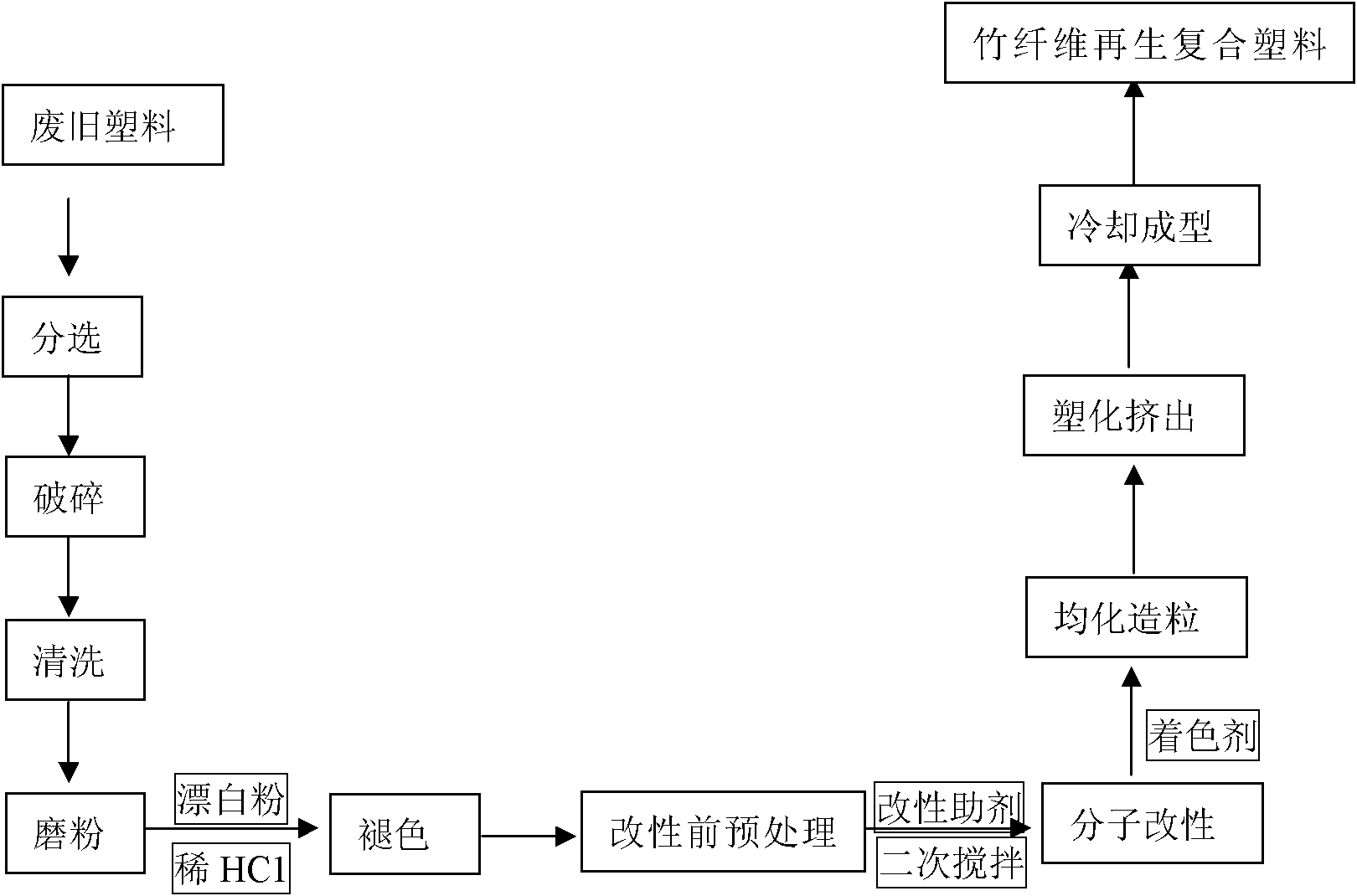

[0037] Embodiment 2: The operation steps of the method invention of improving the color and luster of bamboo scrap waste regenerated composite plastic board are as follows:

[0038] (1) Sorting, crushing, cleaning and milling the waste PVC material and bamboo powder at first, adding bleaching powder, dilute hydrochloric acid and other medicaments to the milled powder to fade the color;

[0039] (2) Send the faded powder to a magnetic stirrer and add azodicarbonamide for pretreatment before modification;

[0040] (3) The pretreated powder is then passed through the "secondary stirring device", adding aluminate coupling agent and butyl acrylate coupling agent to carry out molecular modification of PVC;

[0041] (4) PVC powder particles enter the granulator through the discharge pipe, add colorants and processing aids, knead, homogenize, and granulate;

[0042] (5) After granulation, it is transported to the feeder in the molding workshop through the transmission channel, and en...

Embodiment 3

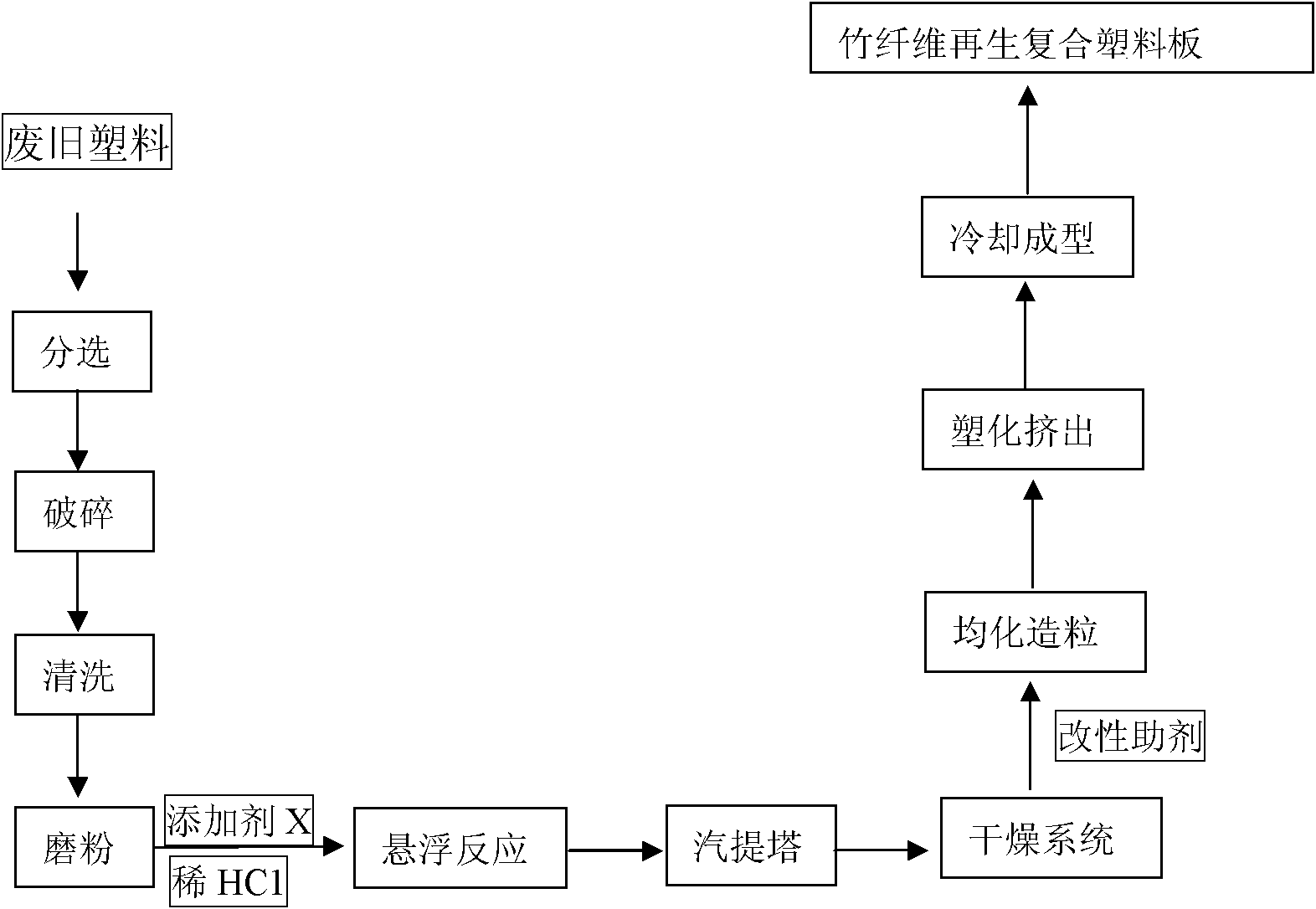

[0044] Embodiment three: the method invention of improving the surface smoothness of bamboo scrap waste regeneration composite plastic plate is as follows:

[0045] Firstly, the waste PVC material and bamboo powder are sorted, crushed, cleaned, and pulverized, and then include:

[0046] (1) Transport the grinding powder to the suspension reaction kettle through the belt, add azodicarbonamide, dilute hydrochloric acid, etc. to stir and react, and adjust the stirring intensity to control the particle size and particle size distribution of PVC, and form the PVC molecule on the particle surface. The coating film makes the PVC resin particles regular in shape and uniform in particle size;

[0047] (2) The PVC slurry directly enters the stripping tower through the discharge port of the reaction kettle. After the azodicarbonamide substance in the PVC particles is removed, it is sent to the drying tower for centrifugal dehydration through a conveyor belt, and then conveyed by a screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com