High-refractive-index resin, preparation method and application thereof

A resin and alkyl technology, applied in the field of high-refractive resin and its preparation, can solve the problem that the coating film is difficult to achieve high refractive index and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

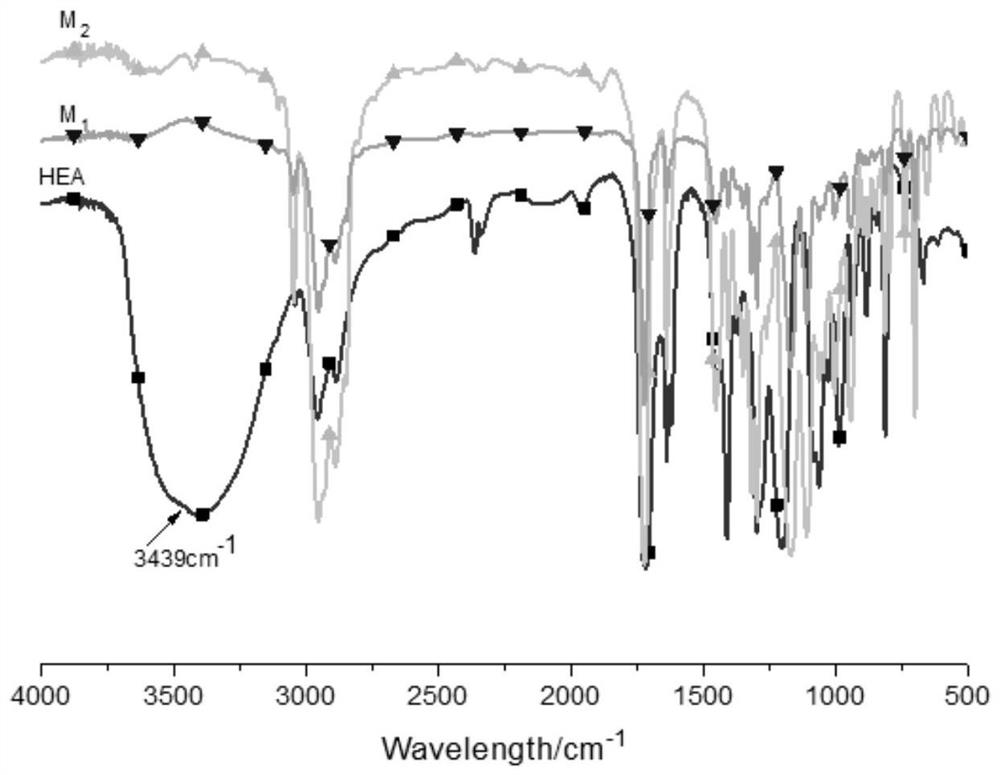

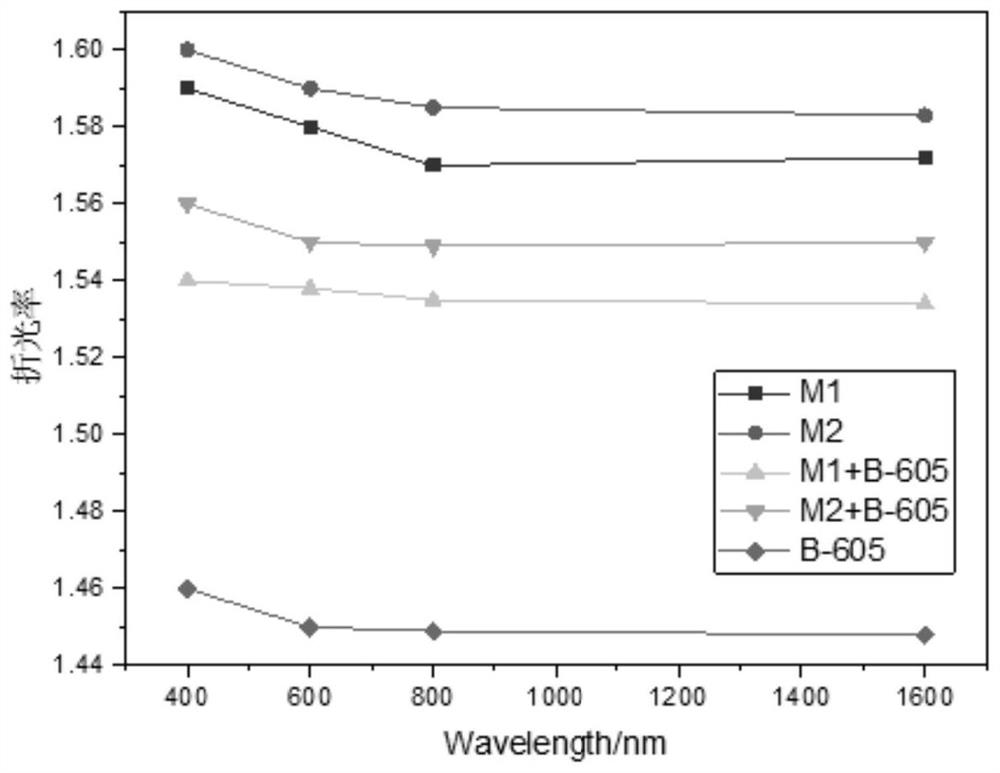

Method used

Image

Examples

preparation example Construction

[0061] Further preferably, the preparation method of the hydroxyl-terminated silicone oil of the present invention comprises: reacting the hydrogen-terminated silicone oil and alkenyl alcohol under a catalyst to obtain the hydroxyl-terminated silicone oil. More preferably, the reaction temperature of the present invention is 90-120°C, for example, 90°C, 95°C, 100°C, 105°C, 110°C, 115°C, 120°C. The reaction time of the hydroxy-terminated silicone oil can be determined according to the method of sodium hydroxide titration, and is not specifically limited. In one embodiment, the reaction time is 8 to 12 hours, for example, 8h, 9h, 10h, 11h , 12h.

[0062] The method of described sodium hydroxide titration is: get the mixture of terminal hydrogen silicone oil and alkenyl alcohol reaction under catalyzer, add in the acetone solution, titrate with 1N sodium hydroxide solution, when the reaction solution that takes out has no bubble (due to The silicon-hydrogen bond will react with ...

Embodiment 1

[0079] Embodiment 1 provides a kind of hydroxyl-terminated silicone oil

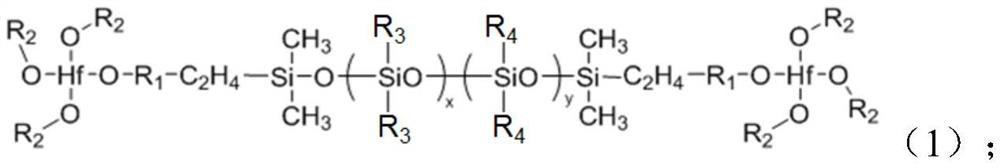

[0080] This embodiment provides a kind of hydroxyl-terminated silicone oil A 1 , its structural formula is as follows:

[0081]

[0082] x mean 18, y mean 22.

[0083] This example also provides the preparation method of the above hydroxyl-terminated silicone oil, including: in a 1L four-necked round bottom flask, add 550g of hydrogen-terminated silicone oil (x average value 18, y average value 22), heat up to 100 ° C, constant temperature 100 Add allyl alcohol (KarstedtPt catalyst 0.005g, allyl alcohol 12.54g) pre-mixed with KarstedtPt catalyst dropwise at ℃. After the addition is completed, the reaction solution is turbid. Continue to react at a constant temperature of 90°C for 3 hours, and the reaction solution gradually becomes clear. Transparent, get 5g of reaction solution in acetone solution, titrate with 1N sodium hydroxide solution, when the reaction solution taken out has no bubbles (due...

Embodiment 2~3

[0087] Embodiments 2-3 provide a kind of organic hafnium modified resin

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com